After the Alaska Airlines incident: Is aviation quality control insufficient? | DW News

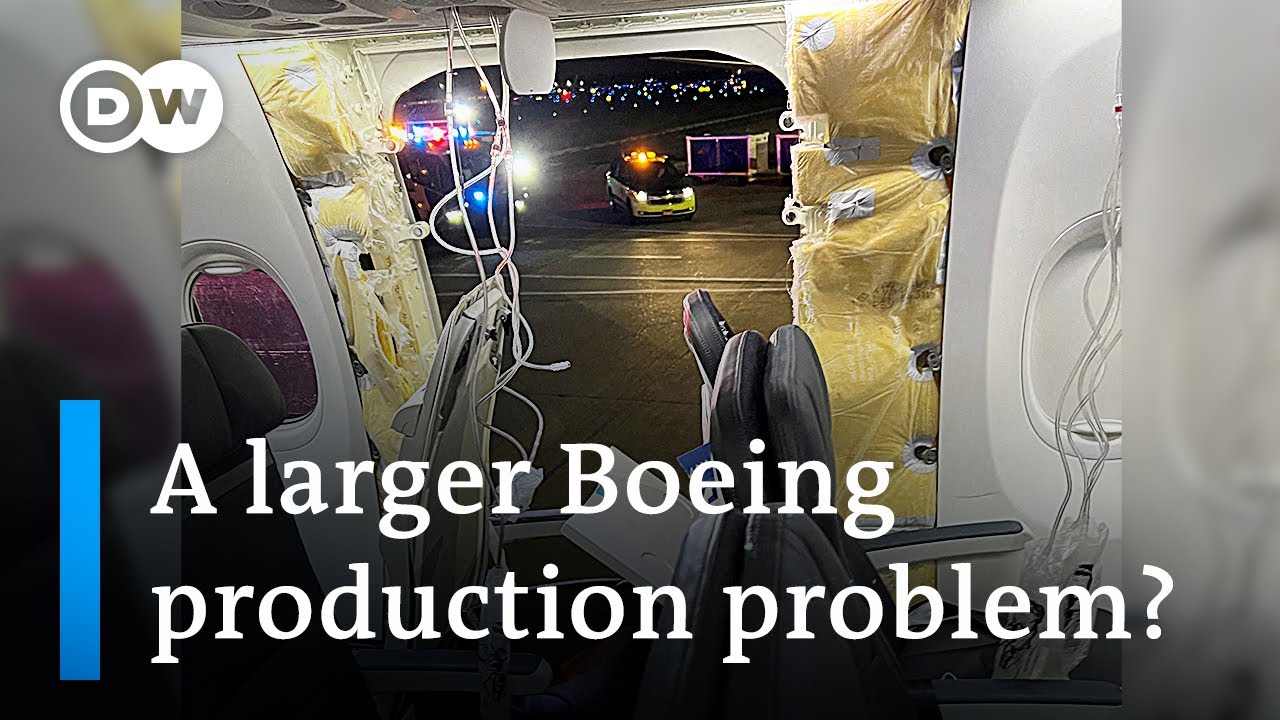

United Airlines has found loose bolts on the door plugs of some Boeing 737 max9 planes during inspections the checks were triggered after a door plug of an Alaska Airlines jet blew out mid-flight last week investigators are still trying to determine exactly what happened now the two US carriers grounded the Boeing

Model after the incident causing hundreds of flights to be cancelled one of the missing pieces of the puzzle the door panel that fell out of the Alaska Airlines flight midair found in the garden of a high school teacher in the US state of Oregon my heart did start beating a

Little faster at that point cuz I thought oh my goodness people have been looking for this all weekend and it looks like it’s in my backyard investigators are still in the process of trying to identify exactly what caused the panel to blow off the Boeing 737 and if it had been properly

Installed the the exam to date has shown that the door in fact did translate upward all 12 stops became disengaged allowing it to blow out of the fuselage uh we found that both guide tracks on the plug were fractured uh we have not yet recovered the four bolts uh

That restrain it from its vertical movement and we have not yet determined if they existed there that will be determined when we take the plug to our lab in Washington DC passengers on board the flight captured the moments after the door panel blew off the plane some reached for oxygen

Masks the Alaska Airlines flight was at an altitude of 16,000 ft when it began its emergency descent with a gaping hole on the side of the the plane the plane landed safely with over 170 people on board us Regulators have ordered a temporary grounding of some Boeing 737 Max 9 jets for

Inspections United Airlines and Alaska Airlines have both identified loose Hardware in several of their 737 Max aircraft including dual bolts that need tightening this contributes to Serious concerns over the safety of the 737 Max model which was involved in two deadly crashes months apart in 2018 and

2019 and for more on this let’s bring in Steven brigh an international Aviation and safety expert he’s the president of the Finnish Association of aeronautical engineers and joins us from tempera thank you so much for joining us here on DW news what do you make of the the fact

That inspectors have now found loose bolts on some other of these planes H hello there Sarah um I’m not surprised that uh other problems have started to be uh discovered this type of event uh indicates that it is based on a latent type failure a hidden problem and

When you go looking for these hidden problems very carefully you find that the problem doesn’t often exist just with one individual unit I.E the Alaskan Airlines aircraft but rather it will affect a much larger number of aircraft and so this this type of event discovering things like this this isn’t

New so do you then share the assessment that the investigations so far indicate a construction problem rather than one with maintenance is that how we should interpret this yeah very much so um you have to put this all into perspective this is a brand new aircraft it’s only been out of

The factory matter of months it’s gone to the customer gone to the airline and they haven’t used it very much they’ve been preparing it they’ve probably done some test flights and then they’ve put it into commercial service what this means is it’s new they haven’t needed to

Do any maintenance at all and what we’re more focused on here these loose bolts these are behind a PL IC door panel so you can’t see them with the naked eye with the the interior panel Vis um when it’s fitted you have to take the panel

Off get a torque wrench out and then start mechanically checking things to see if it’s been installed properly so what sort of scale are we talking about here when we talk about fixing the problem can it be fixed easily if it’s you know a structural problem like what you’re highlighting

There well it’s it’s to me it sounds like it’s an assembly problem in the production phase um we uh until they find the bolts that hold this thing together then we won’t know but what we do know is that other aircraft have got the fastenings the correct fastenings

Attached that’s the most important thing are they the right bolts if they’re the right bolts have they been put in correctly and the ones that they found haven’t and it’s not just one aircraft that they found we’re talking about more than one which then implies there’s a big production

Problem Aviation expert Steven Wright thank you so much um for that perspective that analysis of the situation we appreciate it thank you let’s look at this with Geral vissle he’s an aviation expert and CEO of Airborne Consulting he joins us from Hamburg welcome to DW this is a scary

Story this idea that there were loose bolts on these aircraft we all assume as the traveling public that that airplanes are inspected and and and to within an inch of their lives how could this have happened yeah I feel that’s a a really good question um so normally we know

It’s it’s it’s a problem with the aircraft so we have to consider in general three levels construction production or um the maintenance level so in the case of the 737 Max 9 it the problem appears to be the to be on the uh production level to answer your

Question and to to understand especially what really happens we have to look shortly at the history background of this uh aircraft so normally production of a complete new aircraft is is very time consuming and um it takes a lot of time so this is why an existing aircraft

Is is modified to improve and optimize so the 727 Max what we see here is a modernized version of the um Boeing 737 900 ER and um this version in in normally was allowed to carry maximum of 189 passengers but there were demand of air some Airlines to increase the number

Of passengers so the manufacturer of Boeing has to increase the number of emergency exits as well so and um so and the fuses of the 77 Max yeah has um um has copied this so because it’s based on that aircraft with these extended numbers of emergency exits Alaska

Airline um has only uh a version for 178 uh passengers so they did not need this additional uh emergency exit and they have to repace place this emergency exit with a Fus panel or plug and um normally Fus page are parts are are joined together with rivets but in this case um

It was just mounted with with bolts and um and what we see here and this is this this the answer of your question is that it looks that it was a problem during the manufacturing of the aircraft and that this poles um were not mounted in

That way that it is secured and cannot fly out right so these so if and I appreciate that we are speculating now because we’re only going off news reports but if if this came from the manufacturer like that with these loose bolts it is not normal uh during

Maintenance to check them uh whether or not they’re tight enough it would just be presumed that it is fine yeah the maintenance is based on on an on a maintenance schedule and uh when we talk about fusel maintenance so there’s a longer time period between the the

Maintenance uh uh activities so uh what I think is that it was not a maintenance uh or inspection uh issue because what not was not the time in the maintenance book to look at this special uh uh uh part so um at the end uh it comes back

To the prod production and it was a production issue of of BOE and um I think this is what what what went wrong at that time so from my point of view right so these models have been uh grounded um uh certainly from stopped from flying into American airplace I

Believe the UK has stopped it as well do they get sent back to the manufacturer or does someone with a a big spanner go round all these aircraft and make sure that that these are all tightened up yeah I I I I think it’s it’s around 170 aircraft at the moment um active

Mostly with the United Airlines and also Alaska Airlines so um they are grounded at the moment and have to be inspected and repaired if necessary so Boeing must bear the repair costs and also loss of of Revenue so and the extent to which airlines uh so okay so so they this is

What what goes back to Boeing and and at the end and I think this is the the most uh important part is that the FAA the the relevant Authority in the US they have to independently review the the the production process and and the quality management so to ensure that the uh

Delivery of an aircraft is uh 100% compliant yeah to all safety requirements this is from my point of view the most uh uh uh important part so um I think when when they check the aircraft they inspect the aircraft they can they can fix the problem but at the

End we have to look also at the production P process of Boeing and also of the quality assurance process right and so if all this is found to be down to the the production process this is a disaster for Boeing isn’t it absolutely it is so uh we we we saw

Some some similar problems in the past with other aircraft types um uh linked to the production process so and and uh they already they had a trust problem um and and they repeatedly assured that they fixed it and they work on structures and processes so however it

It does not really seem that that it be uh sufficient and I assume that there must be independent audits of the production process under and under the supervis vision of the FAA in order to Res restore this trust and additionally also the European Aviation uh safety

Agency so the AA will also have to consider very carefully so what to extent to what extent to can rely on boing statements and if necessary demand further in investigations so again it is absolutely serious for boing and and they have to to uh bring back the trust especially on production and quality

Assurance processes so are there therefore wider implications for the aviation industry because as you say there is a there is a maintenance protocol but if you’re not looking for something because you it’s not part of of of what needs to be maintained then surely this might be a problem that

Applies to other models and other manufacturers in this case I think it’s it’s only applied to this mod this specific model as I said with the uh with the emergency exit numbers but you’re right but when we look back and say okay there’s a construction process first uh with the construction of an

Aircraft and and the prototypes and there are a lot of requirements safety require ments before an aircraft gets a type certificate and is ready then to for the mass production and these processes are very very um welld designed and U and they are inspected by the by the authorities so that we can

Assure normally that an aircraft which has the type certificate that is 100% safe okay thank you for talking us through that Aviation expert Geral vissel from Airborne Consulting thank you thank you

Alaska Airlines and United Airlines have found loose parts in the panels, or door plugs, of some Boeing 737 MAX 9 planes during inspections. The checks were triggered after a door plug of an Alaska Airlines jet blew out in mid-flight.

Chapters

00:00 United finds loose bolts on 7373 MAX 9 planes

02:45 Stephen Wright, Finnish Association of Aeronautical Engineers

05:45 Gerald Wissel, Aviation expert

Subscribe: https://www.youtube.com/user/deutschewelleenglish?sub_confirmation=1

For more news go to: http://www.dw.com/en/

Follow DW on social media:

►Facebook: https://www.facebook.com/deutschewellenews/

►Twitter: https://twitter.com/dwnews

►Instagram: https://www.instagram.com/dwnews

►Twitch: https://www.twitch.tv/dwnews_hangout

Für Videos in deutscher Sprache besuchen Sie: https://www.youtube.com/dwdeutsch

#Boeing737 #alaskaairlines

30 comments

This is what happens when businesses control regulators instead of the other way round. The US is one big corrupt plutocracy.

Boeing has nowhere near the quality control of Airbus nowadays. That’s a fact.

Boeing completely ruined the trust of companies in the past years with repeated and unbelievable mistakes with the system design and at the production level.

Complete disaster.

who does Boeing hire to assemble planes crack meth heads?if that panel was not fastened properly who is to say there isn't other loose bolts scary.this is poor workmanship you getting paid do the best job or do something else.there is no second chances in aviation things have to be done 100% with redundancy built in.

We can safely send a capsule to Mars or the Moon but we can't bolt on a panel.

Boeing Quality people call themselves doing quality work are sleeping in the noodles house.

"When one door closes another door opens!" – Boeing

Say what you will about lack of adherence to safety standards, but flying sure is safer today than it was even 20 years ago.

In the end the FAA signed off on this. that the most concerning to me.

Garbage report… this has nothing to do with Boeing… Boeing supplies the “plug doors” un- attached. It is up to the individual airlines to either install a plug, or working door. Proper bolting is up to them. Hopefully Boeing will sue DW for damages. DW should keep their mouth closed when they don’t know what they are talking about.

made in usa

Loose bolts in the door panels of the 737 is akin to a surgeon leaving tools inside the patient after the patient is sewn up. 😂

Well it's not that big issue. Happens very rare. Boeing is not responsible for maintenance of the plane forever. Airlines need to take care of their planes. And bolts etc can become loose with time and usage. Everything wears down. I think it's not that big issue but media trying to make it look big because it's their business to hype every news.

Any Boeing plane done under Muilenberg should be banned .

Your "Aviation Expert" is saying, "They probably did some Test Flights", implying it an option to test fly a New Aircraft Type ? ? ?

I worked in aviation, as a mechanic & maintenance QC Inspector, from 85 thru to 2022, w/ over 2 decades at Alaska Airlines regional carrier based in Portland Ore. In my experience, well over 90% of these so called "Aviation Experts" who do commentary for broadcast News are misinformed, fabricating facts, intentionally omitting relevant information and/or just spinning or exploiting what little the actually know on the subject. After all, they're being paid to "sell" the story.

If you really want to know how the story ends, read up on all the events that occurred w/ a United Airlines owned 747 that suffered an explosive decompression when a forward Cargo Door had its locks fail. When the door departed the A/C, it took an upper level floor section with 9 passengers and their seats attached to it. Boeing laid all the blame on the mechanic who last rigged the door because the NTSB had no door to investigate as it was 14,000ft under water. Two yrs later the U.S. Navy recovered the cargo door & the NTSB reopened the investigation. It was found the mechanic had rigged the door correctly and that the electricly operated door locks were were the problem. Boeing was forced to redesign the locking mechanisms for the door.

First the MCAS and now this

No more flight for every min n evry year all airlibe is there targeting n doing so much terrible thing my condolnce

Only 4 bolts????? Wth?????

The damage to the reputation of the 737 is irreparable. It use to be a safe plane, only other plane i can think of that was safer was the DC3. Ill fly that anyday. Never another 737.

Boeing 🤔 Bo ending finished. No safety No businesses. 😴😴😴

Just learning but if the child did not have his seatbelt on could he have been sucked out?

We will never ever set foot on a Boeing aircraft again. This former aviation giant is in a tailspin incapable of manufacturing a product folks can trust in.

I don't know-isn't this 737 airframe a decades old design which somehow didn't go thru the normal process of having an aircraft design certified when they changed the design-moved the engines? A bit too cozy with The FAA, & The NTSB, eh?

Who de regulated the airline industry telling "US" it would be best when we KNEW it would lead to this? We definitely need third party oversight committees in every industry with the lack of morals in folks these days. We used to take pride in our quality workmanship & longevity of our products-now it's churn n burn everyone/everything just for a buck. De regulation of Industries was a serious error in judgement, & things continue to go down the drain because of it.

Who on earth wants to fly on this horrendous aircraft?

Main thing they are meeting diversity quota who needs safety

I can tell the investigators what caused the problem. Shoddy Boeing engineering.

Look into DEI being a contributor.

What went wrong with Boeing lately?

I will not fly boeing aircrafts

They put profit over safety

The Majority Report had an interview with a former Boeing employee and he said Boeing is caught on record applying for engineering exceptions. Engineering exceptions to avoid regulations and safety protocols. This was negligence. 🫴