3D-printed homes get built by robots in Texas neighbourhood

Work is nearing completion on the world’s largest 3D-printed neighbourhood.

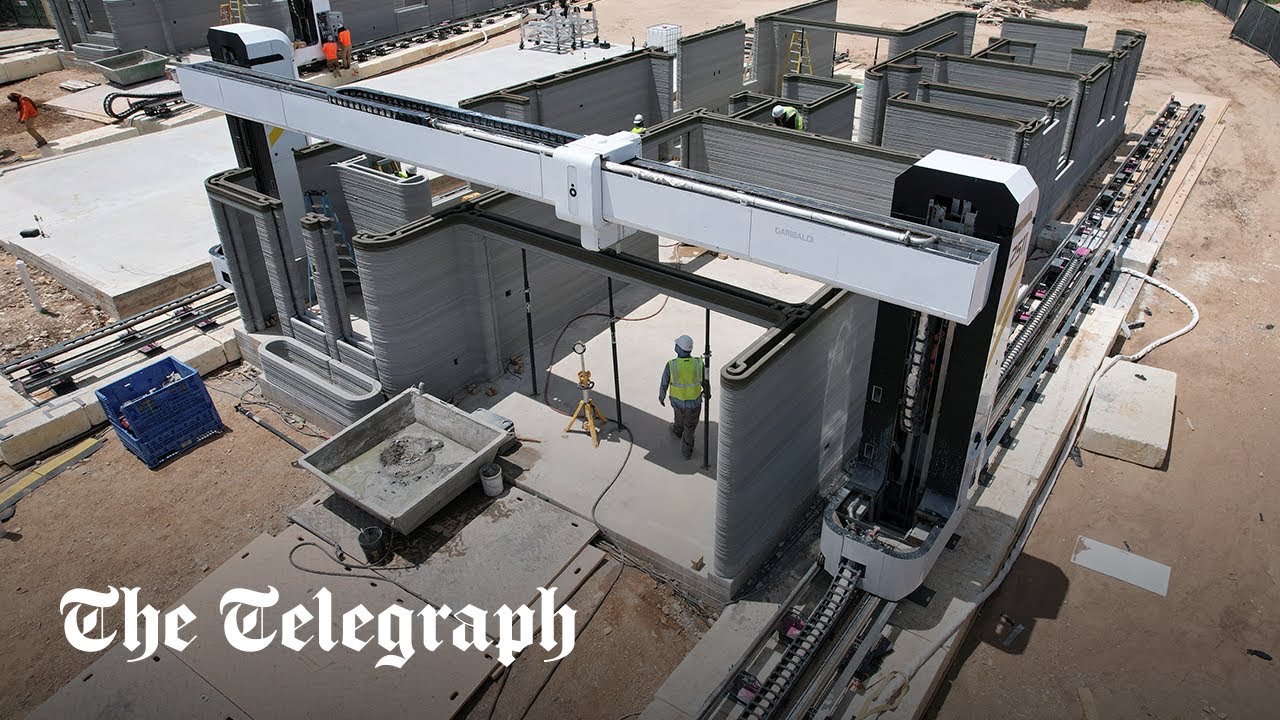

Some 100 homes have been built by the robotic printers since November 2022.

The ICON Vulcan printers measure 45 feet wide and weigh 4.75 tonnes.

Concrete powder, water, sand and other additives are mixed together and pumped into the printer.

A nozzle then lays the concrete mixture layer by layer along a pre-programmed path.

The single-story 3D-printed homes take about three weeks to finish printing.

Only the walls are printed – the foundation and metal roof are installed traditionally.

The walls are designed to be resistant to water, mould, termites and extreme weather.

3D printing homes is faster, cheaper and minimises waste of construction materials, says ICON.

The 3D-printed homes at Wolf Ranch in Georgetown, Texas range from $450,000 to $600,000.

35 comments

😮

Frost

Free East Turkestan / Free Kurdistan / Free Western Sahara / Free Northern Ireland/ Free Balochistan

amazing, please research further to build 6 to 8 story buildings by 3d printers and halve the construction costs by doing that.. South Korea needs that as soon as

yeah 500K is a little steep……

$450-$600k for a 3D printed house? How on earth is that economical? They are price gouging.

No need of mexicans

I feel bad for these entrepreneurs trying to get a foothold in homebuilding in Texas. The government is letting in so much cheap labor that its going to crush this technology.

DEI hire

Those ridges are gonna need some serious dusting 😉

Largest? There are more?

Modern twist on a mud hut!

Way overpriced jeez I thought this was supposed to be cheaper??!!!

Slava Ukraina ❤

I don’t think I could get used to those interior walls

More tradesman out of a job and sat at home claiming money off the state.

This is putting thousands of illegal immigrants out of a job. Thanks Obama.

Hope the local communities band together to allow this company to go bankrupt. All it does is increase the price of building the home all the while excluding actual humans of career paths😂

i see more workers than if it was a normal construction ….

Less and less jobs

Almost all 3D construction startup stop operating after covid.

So many questions: How thick are the walls, what is the insulation like in terms of heat and cold, why are there no PV panels on the roofs, why not render at least the interior of the walls smooth ? And so on..

China has been making entire cities like this for years.

I hate the texture

I was waiting for these 3D printed houses, which can be built by machines. This saves a lot of hard labor and saves the cost of making this house. Future, let's go !😄

Why is no mentioning how uneven and inconsistent the building looks

still expensive so what is the point?

Hard NO!!

Finally a house in USA not made of paper 😂😂

i will never buy such house

When this stupid project started 10 years ago, it was going to be used to build single person homes that were affordable, but no, the developers realized it would be better to build much larger homes for hugely higher $/sq ft. A good idea thrown in the trash can. Better go back to SIP panel or prefab factory houses. Even a HomeDepot shed for $20k plus upgrading.

nice we need badly in canada homelssnss rising by the min

The house is “loud”. It needs acoustical treatment.

"Cheaper" doesn't mean a lower price for home buyers, it means more profit for the crooked contractors.

Three weeks to make what is basically a modern mud hut? A good crew can frame out a small house in 3-4 days. It's also going to be a headache when the slab settles, and the walls start cracking.