Norwegian shipbuilder Vard has partnered with the Norwegian University of Science and Technology in Ålesund and other key stakeholders to explore the potential of nuclear propulsion in maritime applications through the Nuclear Propulsion in Shipping I (NuProShip I) project.

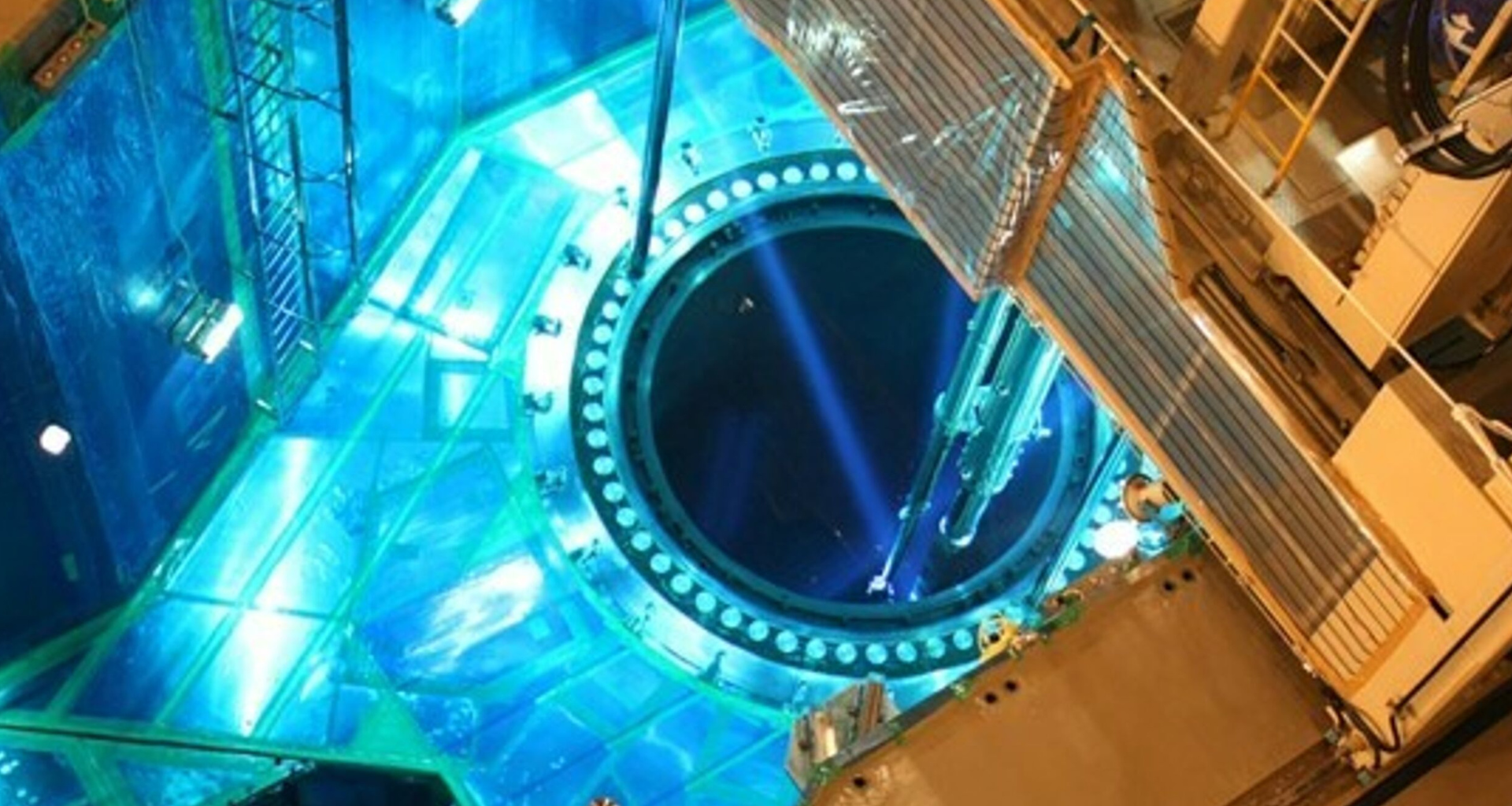

This initiative evaluates the feasibility of using fourth-generation nuclear reactor technologies in commercial shipping, offering a potential zero-emission alternative to fossil fuels.

The global shipping industry emits approximately 1,000 million metric tons (Mt) of CO2 annually, accounting for 3% of global emissions, making decarbonization critical.

The International Maritime Organization projects that shipping emissions could rise by as much as 50% by mid-century without stringent measures. With the NuProShip, Vard seeks to address this challenge and promote sustainable maritime operations.

The reactors behind NuProShip’s maritime advances

This project involved an extensive assessment of 99 companies that develop advanced reactor technologies. This eventually led to the selection of three promising reactor types:

Kairos Power: High-temperature Molten Salt Reactor (MSR)

Kairos Power’s design utilizes a fluoride high-temperature molten salt reactor, which is notable for its use of TRISO fuel particles. These particles are known for their high resilience and containment capabilities, making the reactor highly efficient for maritime applications.

This reactor operates at high temperatures, increasing thermal efficiency and potentially reducing operational costs.

Ultrasafe: Helium-cooled gas reactor (HTGR)

The helium-cooled gas reactor from Ultrasafe also employs TRISO fuel particles, known for their durability and safety features. This reactor type leverages helium cooling, which enhances thermal efficiency and offers negative temperature coefficients, reducing the risk of overheating and ensuring a safer operation under extreme maritime conditions.

Blykalla: Lead-Cooled Fast Reactor (LFR)

Blykalla’s innovative approach features a lead-cooled fast reactor using uranium oxide fuel. This technology provides high efficiency and advanced cooling mechanisms through lead or lead-bismuth eutectic, which serves as a coolant, offering significant safety advantages and the capability of operating at higher temperatures.

Integration and collaboration

Vard’s role extends to integrating these reactor systems into various vessel types while facing the technical challenges of retrofitting nuclear reactors in maritime settings. This work is supported by a consortium that includes DNV, the Norwegian Maritime Authority, shipowner Knutsen Group, and Spanish nuclear consultancy IDOM.

Looking ahead: NuProShip II

Following the successful completion of the NuProShip I project on December 31, 2024, it will evolve into NuProShip II. This next phase involves expanding the consortium to include insurance companies, a step Vard identifies as critical for evaluating the business viability of nuclear propulsion.

Using nuclear technology in maritime shipping will not only help cut greenhouse gas emissions to meet global sustainability goals but also extend the life cycle of vessels and remove the uncertainty of fuel and refueling infrastructure.

However, the path forward involves addressing several challenges, including regulatory frameworks, public perception, and the technical complexities of deploying nuclear technology in commercial shipping.

Meanwhile, the NuProShip project, backed by the Research Council of Norway, is leading the industry to a more sustainable and productive future.