A paradigm-shifting research focus by Texas A&M and the U.S. Department of Energy Advanced Research Projects Agency-Energy (ARPA-E) is changing how petroleum coke is processed.

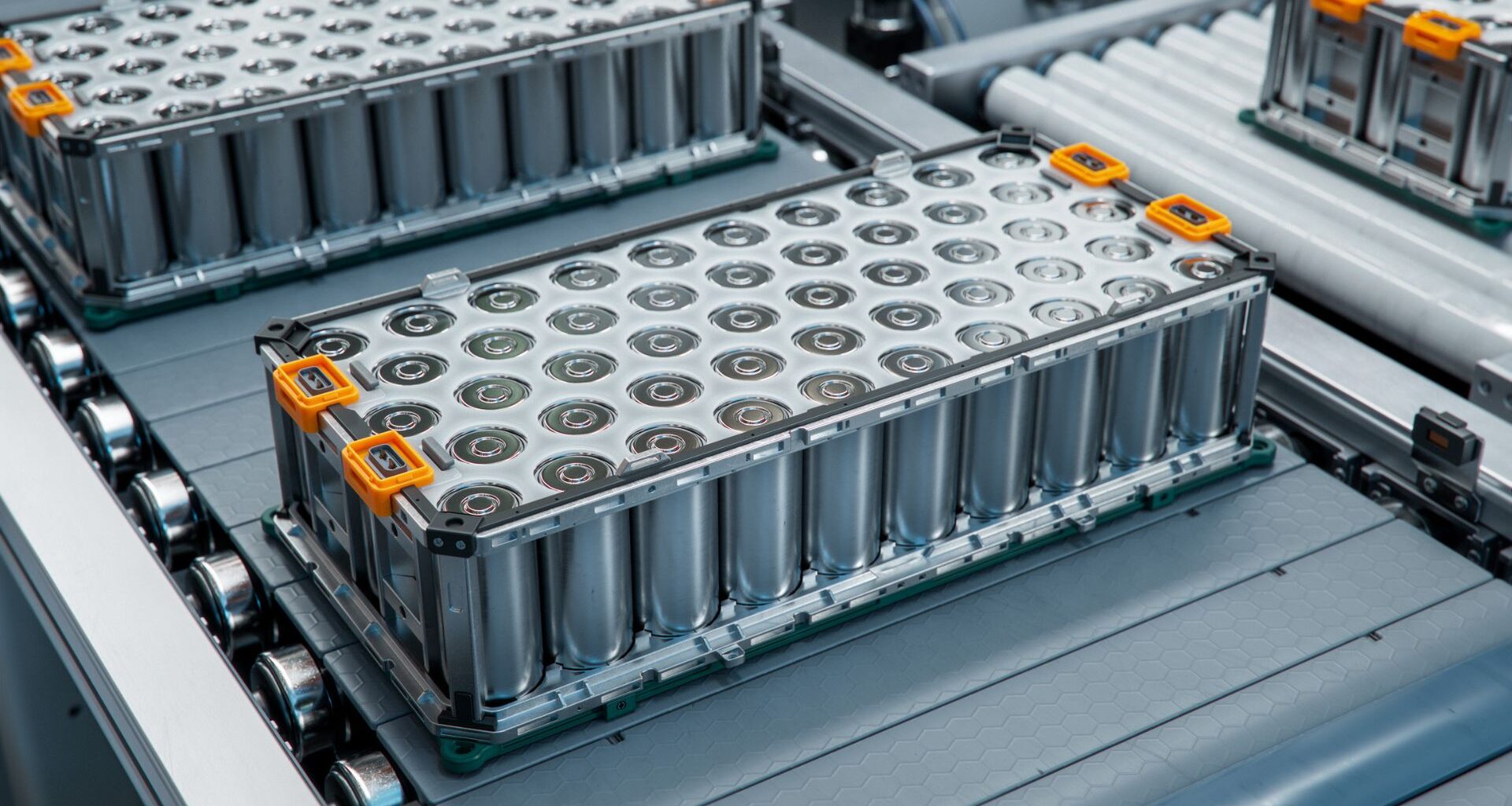

The $3 million, three-year project seeks to refine the process of converting petroleum coke to synthetic graphite—a vital component for energy storage systems, such as lithium-ion batteries—and make it much more efficient and less harmful to the environment.

“We are not only just solving one problem, in a sense this also reduces emissions,” said Dr. Faruque Hasan.

“Our grant is about changing the process by using catalysts so we can make petroleum coke into synthetic graphite that’s good for applications like batteries and for reducing American reliance on foreign sources of graphite,” Dr. Micah Green, associate department head of Texas A&M University Artie McFerrin Department of Chemical Engineering, said.

A sustainable approach to graphite production

Petroleum coke, a product of petroleum oil refining, can be converted into graphite, but the traditional method consumes a lot of time and energy, requiring the material to be heated as high as 5,000° Fahrenheit. The researchers at Texas A&M, on the other hand, have invented catalytic graphitization that drastically reduces the processing time as well as the temperature needed for treatment.

The innovative approach increases productivity while simultaneously lowering the carbon emissions and costs incurred by conventional synthetic graphite production.

“My group is very involved in the actual synthesis and developing the catalyst and showing how that process can be scaled up,” Green said. “We have already done some proof-of-concept experiments at the lab scale, but to transition into industry, we need to show that it can be done at a large scale.”

This effort is a part of ARPA-E’s VISION OPEN initiative, which aims to improve different crucial components of the energy industry, such as nuclear fusion, grid integration, and the development of sustainable chemicals and fuels.

The initiative looks to not only mitigate emissions but also fortify domestic supply chains by transforming petroleum coke into useful carbon goods instead of burning it for fuel.

Scaling up for industrial applications

Although the initial testing phases have been completed successfully on a small scale, the next obstacle is scaling the process up to industrial levels.

“My group specializes in computational modeling, simulation and optimization of emerging technologies,” Hasan said.

“In particular, we will determine optimal process design and operability domains for this exciting new technology developed in Dr. Green’s lab for producing highly value-added chemical products from petroleum coke in a sustainable manner.”

If this approach proves to be viable, catalytic graphitization would dramatically increase the ease and sustainability of graphite production without the reliance on foreign sources. It also opens the door for petroleum coke to be repurposed into high-value materials, contributing to cleaner energy solutions and a more circular carbon economy.