The light reaching Earth has a variety of frequencies, some of which are visible to us and others that are not. Of these frequencies, shortwave infrared (SWIR) stands out for its unique properties that make it extremely useful for Light Detection and Ranging (LIDAR) systems.

LIDAR is a system that calculates distances using laser pulses, similar to how SONAR uses sound waves.

SWIR waves are unique in that they don’t pass through the cornea and lens of the human eye and reach the retina, which is hazardous. This makes SWIR eye-safe and ideal for practical applications such as LIDAR systems.

Researchers at the Institute of Photonic Sciences (ICFO) have demonstrated a new method to synthesize silver telluride (Ag₂Te) colloidal quantum dots. Quantum dots are used in LIDAR systems as light detectors (or photodetectors).

The new method addresses the challenges associated with traditional SWIR photodetectors, which use toxic heavy metals like lead or mercury in the quantum dot components.

Silver telluride colloids, a more environmentally friendly alternative, have been previously investigated for use in quantum dots. Despite their potential, several obstacles limit their widespread use.

The new study addresses these challenges by optimizing the surface engineering of silver telluride colloidal quantum dots to extract maximum efficiency while still being environmentally friendly.

Toxicity associated with quantum dots

Quantum dots are small semiconductor particles with diameters ranging from 2 to 10 nanometers. For comparison, around 15,000 quantum dots could be arranged next to each other along the width of a human hair.

Electrons within a quantum dot are confined. These quantum confinement effects lead to the unique electrical and optical properties seen.

The use of toxic metals for their components arises from their inherent stability and optoelectronic (light and electrical) properties, which makes them a good candidate.

Although safer alternatives like silver telluride colloids are available, they are challenged by noise, slow reaction times, and a limited range of light detection, affecting their effectiveness in detecting bright and dim light.

Surface engineering

The researchers approached these challenges using two steps.

They started by optimizing the synthesis of the silver telluride colloidal quantum dots. Improving the process allowed them to eradicate surface defects on semiconductor particles, which are known to decrease efficiency.

The second step is where the innovation lies and happens post-synthesis. Researchers applied silver nitrate to the thin film of the quantum dot after the synthesis.

The process of doping, which involves applying silver nitrate, introduces impurities to the quantum dots, altering their electronic properties.

In the case of these quantum dots, the silver nitrate changed the quantum dots from p-type to n-type semiconductors. The p and n indicate whether positive or negative charges are responsible for the current flowing in the material.

While the p-type quantum dots show low performance and high dark current, the n-type does not have this issue.

Eye-safe LIDAR applications

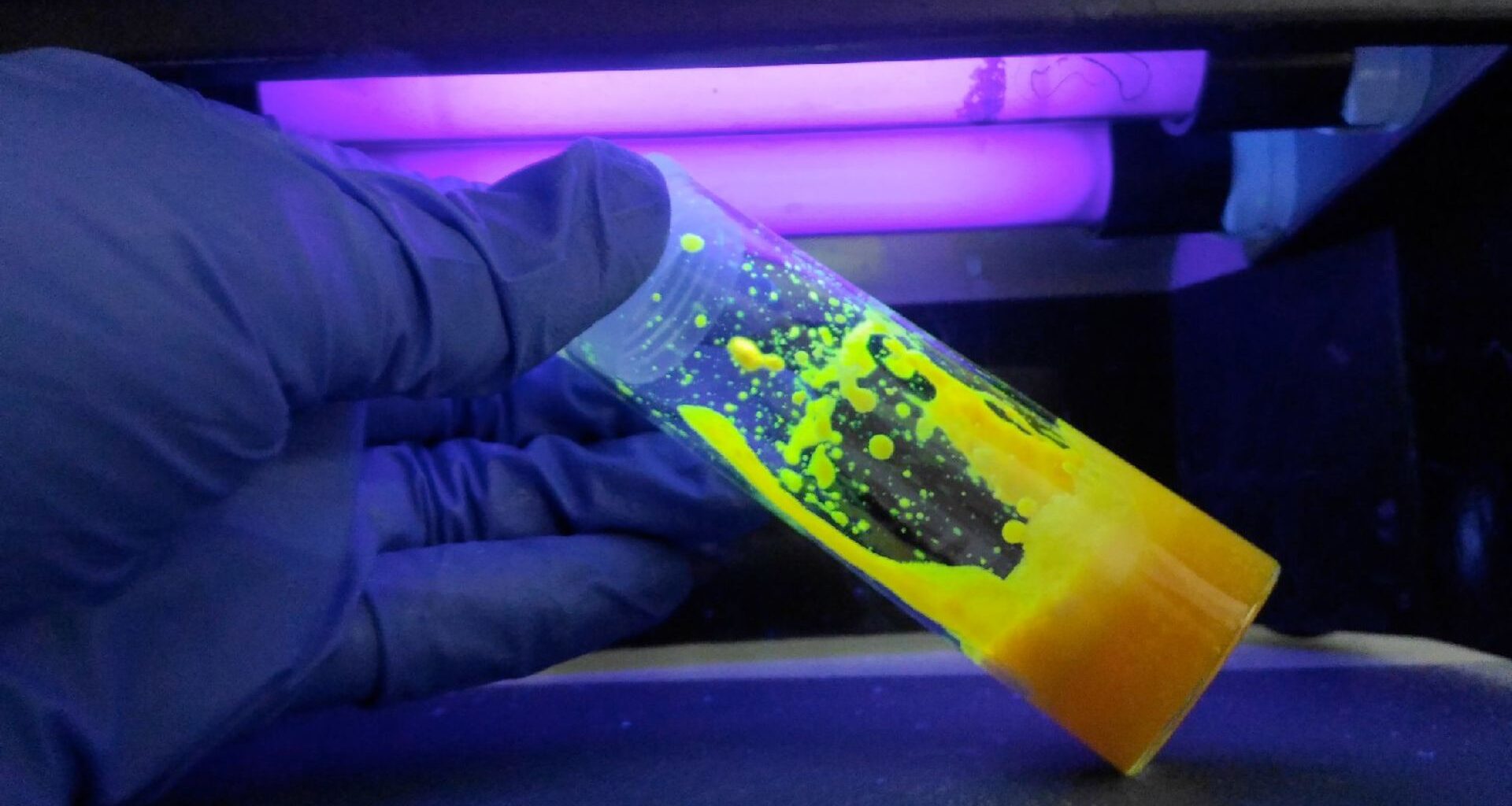

The researchers tested the performance of their SWIR photodetector made of silver telluride colloidal quantum dots.

The photodetector significantly reduced the dark current, reducing noise and improving accuracy. With a 30% efficiency in capturing light of a given wavelength, the device showed increased efficiency in detecting light.

Further, the detector has a quick response time of just 25 nanoseconds, allowing it to measure distances accurately. Finally, the detector can handle a much wider range of light intensities.

Using these environmentally friendly quantum dots, the researchers built the first proof-of-concept for a SWIR LIDAR system. The prototype accurately measured distances of more than 10 meters, with a margin of error of only 0.1 meters.

The findings are encouraging for the possible applications of these systems in areas like environmental monitoring, consumer electronics, and mapping.

“At the beginning of the project, we didn’t expect such a significant leap in the final device performance,” said co-author Dr. Yongjie Wang from IFCO in a press release.

The findings of the study are published in Advanced Materials.