Meeting client requirements of a 200-year design life for the Kruunuvuori Bridge in Finland demanded ingenuity in structural engineering and material choices.

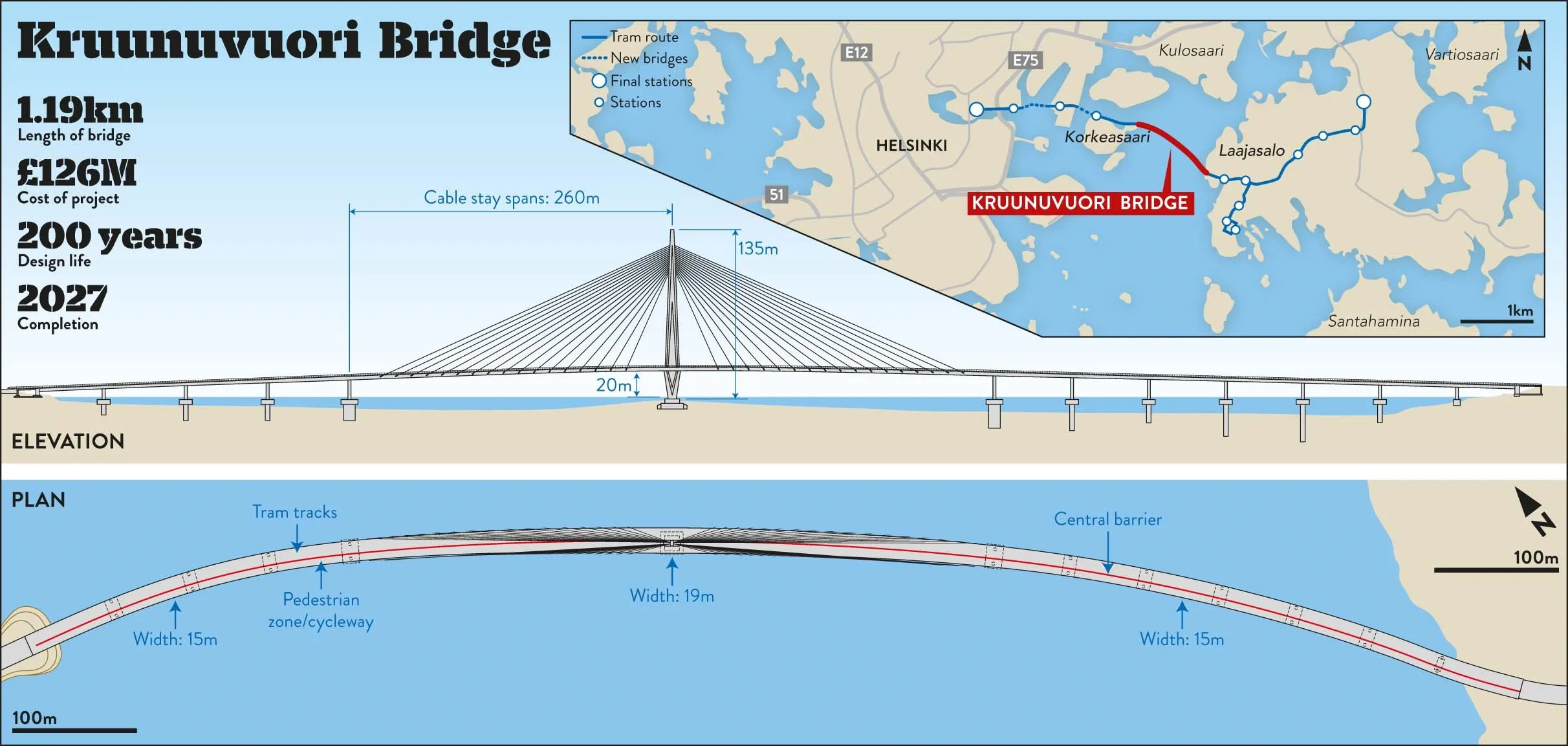

The 1.19km-long Kruunuvuori Bridge being constructed on behalf of Helsinki City Council to link the islands of Laajasalo and Korkeasaari will be integral to their enhanced connectivity to the city centre. When completed, it will be Finland’s longest and tallest bridge.

The bridge will also have international significance, as it will be among the world’s longest bridges built solely for public transport, pedestrians and cyclists. The €150M (£126M) Kruunuvuori bridge is one of six being built as part of a £505M project which will extend the tram network 9km from the city centre to Laajasalo, where a major residential development is being built.

Having an unusually long design life of 200 years also puts this bridge on the international map. “120 years would be a typical design life for bridges of this scale,” says UK-based Knight Architects director Tom Osborne.

Helsinki City Council head of project management for major infrastructure projects Ville Alajoki says the decision to construct to a 200-year design life resulted from a cost-benefit analysis, which translated a lifespan expansion into monetary terms. The client found that the benefits of the selected design life justified the additional investment and strengthened the business case for the bridge’s construction.

“It is a big bridge and therefore a big investment. But taking a 200-year position on the returns of that investment – in both financial and climate terms – shows that big projects need to be paired with a long-term view,” says Osborne.

Concept to final design

Helsinki City Council approved a wider city master plan in 2003, which included the development of a new housing area in Kruunuvuorenranta in the western part of Laajasalo. With thousands of people expected to reside in the area, it is vital for them to have access to public transport to the city centre.

Alajoki says the council explored both tunnels and bridges as connectivity options, as it was considering whether the optimal solution was to expand the existing underground system or tram network. In 2008 the decision was made in favour of the tram.

The international design competition for the Kruunuvuori bridge was launched four years later. “We didn’t specify the bridge type. We specified that we need to get from point A to point B and that it is to be used by pedestrians, bicycles and trams. It was up to the competition contenders to give us ideas about how that connection would be made,” says Alajoki.

He says 10 designs were submitted. “We had a variety of ideas. For example, there were closed bridges; and two-level solutions, where the transport methods were separated into different levels. We had different alignments, from a straight long line to deviating lines. We had some more traditional design ideas and some that went a bit over the top.”

The winner of the competition – announced in 2013 – is a cable-stayed bridge featuring a diamond-shaped pylon, designed by Knight Architects and WSP Finland. “The diamond was a reference to the Crown ownership of the area, so it was founded in the identity of the city,” Osborne says.

With a height of 135m, the pylon is one of the tallest structures in the city and the country, making the bridge a landmark.

“Building something that is quite tall and distinctive was perhaps not the obvious thing [as the city is low-lying] but there was a good reason. Having a central tower allowed the skyline at deck level to be much less cluttered than having many smaller towers. The water gets quite deep on either side of the tower, and so having smaller spans would have been more expensive,” Osborne explains.

The bridge alignment is curved for structural reasons. WSP Finland business area director for bridges Sami Niemelä explains that curvature was needed to balance the transverse flexure of the pylon caused by deck weight, because the pylon is not standing in the middle of deck. “The asymmetrical position of the pylon in relation to deck is a consequence of the difference in width between cycling/pedestrian lanes passing the pylon from the south side and tram lanes passing pylon on the other side,” he says.

Osborne adds that this alignment enhances active travellers’ experience. “We want people to be able to see where they are going. On a bridge this long, if you just have a straight plan alignment, you get a vanishing point and you can’t see one end of the bridge from the other. That can put people off, as it can make the crossing feel impossibly long.”

The bridge’s width varies from 15m to 19m – the widest points being around the pylon – with a 20m maximum clearance.

Aside from the abutments, the bridge has 12 piers. Pier number 6 is the pylon support and separates the two cable stayed spans which are 260m long, with the length of the other spans varying between 48m and 66m.

The 68 cables connect to the pylon at a height of 100-122m. Weather conditions were taken into account for the selection of steel cables. Even though ice accumulation on stay cables is rare in Scandinavia according to Niemelä, it was a parameter that needed to be considered.

There were discussions with manufacturers about solutions such as electrical heating and surface texturing. “Texturing was chosen because it is a low maintenance solution,” he says. “In the instances that there is a lot of ice on the stayed cables, there is the possibility of mechanical removal.”

Particular attention was also paid to the parapets’ design, as they play an important role in the active travellers’ experience. The bridge has three parapets – on the south side where the pedestrian zone/cycleway is located; on the north side where the tram tracks are located; and on a central barrier separating the active travel zone with tram zone.

Commenting on the parapets’ design, Osborne says: “We wanted to strike a balance between blocking the wind and not creating negative amounts of enclosure, where you’re behind a huge glass screen or something that would make you feel you are inside.”

The parapets will be made of stainless steel, as they must be robust enough to sustain contact with a snow plough.

“Each parapet looks like a single element that has been cut or curved. So, the south parapet looks like it was a flat sheet that was bent outward. Rather than, as is typical, being edge-on to the wind, it’s face-on which gives it a porosity of 50%. We are basically adding wind deflection properties to the parapet, rather than having a parapet and then adding a wind barrier on top of it. It doesn’t entirely protect you from the wind, but it gives some wind comfort.

“The middle parapet has an impact barrier in case of tram derailment. We wanted to mask this big bit of concrete, and allow some views, so it twists 90°. The north parapet is on the leeward side of the wind, so we put it edge-on to maintain views.”

The bridge design also includes generous seating provisions to give pedestrians the opportunity to stop and rest.

When completed, the €150M (£126M) Kruunuvuori bridge will be Finland’s longest and tallest bridge (Picture credit: Knight Architects)

Designing for 200-year life

“A major challenge for us designers was that the design life for this bridge is 200 years. There are some parts that can be replaced over time, but the most critical structural parts – the pylon, piers and deck – cannot,” Niemelä explains.

The pylon and piers are made of reinforced concrete, while the composite deck features two longitudinal steel I-girders with a height of 2.6m, with concrete placed on top with an average thickness of 270mm.

“The pylon and piers will face an aggressive environment [due to Finland’s winter weather conditions] so we needed to design concrete that should withstand those 200 years,” says Niemelä.

For the development of the concrete specification, WSP Finland worked with professor Jouni Punkki from Aalto University, who has researched the use of concrete across Scandinavia for decades.

The piers in the sea are the most susceptible to corrosion, so particular attention was paid to their design so that the required design life can be achieved. Their design involves the use of stainless steel on the outer layer of rebar, as well as a steel outer case at low-level to resist damage from ice.

“The distance from the concrete cover to stainless steel rebars is 40mm. They are not structural; they are just preventing cracking of the concrete’s surface. The structural steel is conventional, but there is a concrete cover of 10cm,” Niemelä explains.

Commenting on the use of the stainless steel, Osborne says: “It has a high cost. You could imagine some clients not wishing to take on that cost, because they’re not going to be around in 200 years to benefit from those decisions. So, they were taking a really long-term view, which is something we see regularly throughout Nordic projects.”

For the deck, the team focused on design for fatigue for the steel parts because steel welds are the most sensitive to fatigue. “What we tried to do is to make the steel structure as simple as possible. It sounds easy, but we also had to make sure steel consumption was not going to be too high,” says Niemelä.

To eliminate issues related to water infiltration, the deck was designed as a single unit so that there are no intermediate joints.

Niemelä adds that when the design work started, the team did not have a loading model for the tram, so WSP worked with the client to produce one. It then made an estimation about how much tram traffic there will be on the bridge over 200 years “and from this estimation, we produced the design for fatigue of steel parts”.

Regarding non-load bearing elements that will need to be replaced over the next 200 years, the team designed these for a long life and low maintenance requirements. Osborne adds that “there was no room for decoration, because any decoration would surely fail after half the bridge’s life”.

The use of concrete, steel and stainless steel to secure its 200-year life has inevitably increased Kruunuvuori Bridge’s embodied carbon. Osborne is a strong supporter of the industry’s efforts to reduce embodied carbon, but highlights that sometimes it is important to view carbon impact more holistically.

“People often focus solely on embodied carbon, because that’s the easy thing to measure. But you shouldn’t judge the entire success of a project on the embodied carbon number, because you can spend quite a lot of embodied carbon achieving positive sustainability outcomes,” says Osborne.

“People should start to focus, particularly in the world of infrastructure, on the carbon payback period. So, if this bridge saves vehicular journeys because people ditch their cars and cycle or get on the tram, then the bridge will actively reduce carbon as a result of being built. And if you can measure that, you will be able to establish a carbon reduction rate and therefore a carbon neutral point and payback period.”

Osborne highlights that with the bridge’s design life being double that of some modern bridges, any additional embodied carbon will be significantly less compared to having to build another one.

The piers on the water are founded on piles with a diameter of 1000mm or 1200mm and with a maximum depth of around 40m (Picture credit: Aarni Salomaa)

Construction progress

Even though the decision for the tram route was taken in 2016, the final budget for the eastern side of the project – which includes the Kruunuvuori Bridge – was only approved in 2021. Alajoki says there were challenges related to securing funding and exceptionally strict requirements had to be met to secure environmental permits.

Construction works started in October 2021. “We started with building a working bridge along Kruunuvuorentanta towards the pylon,” says TYL Kruunusillat project manager Jari Humalajoki, adding that the fabrication of the deck’s steel structures also began in late 2021.

The construction of the substructure started in early 2022 and was completed in the summer of 2023. Humalajoki says the piers on the water – except for the pylon support – are founded on piles with a diameter of 1000mm or 1,200mm and with a maximum depth of around 40m. “

There were 62 piles in total,” says Humalajoki. “The pylon is built on a rock foundation. The foundation of the pylon is 9.5m below sea level,” he adds.

The contractor had to work with different ground conditions: rock, clay, dredging and fill soil. “Each subsoil condition requires its own special attention and working method: piling or dynamic compaction. All of these are common working methods in Finland, but different working methods require their own special equipment and make the work more difficult.”

Limitations on marine engineering operations for environmental reasons added to the project’s complexity. “There are seagulls’ nests on two islets near the pylon. During the seagull nesting season from April to the end of June, work below deck level is prohibited within 250m of the islets. Additionally, sea trout spawning occurs between August 15 and the end of September, so no underwater work can be done during that period,” says Humalajoki.

Construction of the Kruunuvuorenranta side of the bridge was completed in late 2022, while the Korkeasaari side was finished the following summer – when the sections of the cable-stayed section were lifted into place.

“The concreting and insulation of the bridge superstructure was carried out during 2023 and 2024,” says Humalajoki, adding that construction of the pylon was completed in January this year.

Delivering the exceptionally long design life has created challenges for the contractor. Humalajoki gives some examples: “Concrete has additives that make it more durable, but these additives made the concrete more difficult to work with.

“The 200-year lifespan requirement has led to more complex structures, for example the use of stainless steel in addition to normal reinforcement.” He notes that the steel grades used for the project, which are more durable, are more difficult to weld.

Humalajoki adds that the overall project has been technically challenging because cable-stayed bridges of this size have not been constructed in Finland for decades, resulting in a lack of workers with relevant experience.

Alajoki says the Kruunuvuori bridge should be open for pedestrians next spring. In 2026, the tracks for the tram will be installed and tests will be carried out, with trams expected to officially start crossing the bridge in 2027.

Like what you’ve read? To receive New Civil Engineer’s daily and weekly newsletters click here.