BHPian Jaggu recently shared this with other enthusiasts:

This is the last part of the trip after the museum visit and the S Class experience drives. We are already running a little late and need to rush to Rottweil from the Immendingen Test facility for our last workshop. And we arrive just in time at a beautiful old power plant that is going to be the venue.

This power plant was built during the First World War and has been turned into an event venue after decommissioning. One can still see the conveyor belt for the coal and various other artefacts from the old era when it was an actual power station. But we are not here for the history and nor are we allowed any kind of camera, cell phone, smart watches or even smart glasses. Cell phones, even when allowed during the workshop, had their cameras stickered off to keep any kind of mischief away! You must be wondering why all this secrecy surrounding the event.

We are here at Rottweil for a sneak preview of the CONCEPT AMG GT XX!

AMG being the high-performance subsidiary of Mercedes-Benz, has been churning out performance-oriented models since 1967. It started as an independent outfit started by Hans Werner Aufrecht and Erhard Melcher. The original name was coined as Aufrecht, Melcher, and Großaspach (Großaspach being Aufrecht’s birthplace). In 2005, AMG was bought over by Mercedes and is now the core of performance-based development that is being done at the company. AMG has in recent years started working on hybrids as well as high-performance variants of EQS and EQE.

CONCEPT AMG GT XX – a New Dimension of PerformancePioneering technology programme offers insight into the first series-production model based on AMG.EA high performance architectureRevolutionary drive concept with three axial flux motors delivers more than 1,000 kW (>1,360 hp) peak outputGroundbreaking high-voltage battery with direct-cooled cylindrical cells enables supreme, sustained performance on the road and at the charging stationThe concept vehicle can recharge energy for about 400 kilometres of range (WLTP)1 in around five minutes – the distance from Affalterbach to Spa-FrancorchampsFour-door coupé packed with innovations inside and out

CONCEPT AMG GT XX is a tech program that gives us a sneak peek into a brand-new four-door sports car from Mercedes-AMG. This car is packed with three axial flux motors and a high-performance battery that’s been developed from scratch. It’s a revolutionary drive concept that takes performance to the next level. And guess what? All the best minds from Mercedes’ global R&D network have been working on this project, from Mercedes-Benz in Sindelfingen and Untertürkheim to Mercedes-AMG in Affalterbach and YASA in the UK, as well as their Formula 1 drivetrain experts at Mercedes-AMG High Performance Powertrains in Brixworth. It’s an incredible collaboration that promises to be a game-changer in the world of sports cars!

Exterior: rebellious design with first-class aerodynamics

With its dynamic fastback, low-slung bonnet and sharply raked windscreen, the CONCEPT AMG GT XX is a statement of the brand’s signature sports car performance. The striking colour scheme in sunset beam orange while the AMG specific front grille with ten vertical struts now comes with more oval and concave form. The Mercedes star is integrated into the middle. The slender, rectangular auxiliary headlights are recessed into the outer edges of the grille. The vertically arranged main headlights has low beam and high beam stacked one on top of the other.

Did you notice those cool two-part air outlets on the bonnet of some motorsport cars? They’re a classic feature that’s been around for ages. These outlets have a practical purpose – they help to dissipate the warm air from the cooling modules in the front of the car. This way, the engine stays cool and ready to race. And guess what? The front splitter on these cars is designed to enhance the cooling effect. It extends all the way around the front of the car, with an air curtain that reaches up to the front wheel arches. It’s like a built-in cooling system. The bonnet extends till the wheel arches and also adds to the overall look of the car, with its distinctive sports car genes highlighted by the two power domes. It’s a sight to behold.

The side view is all about the low-slung front end, where the fenders flare out towards the front wheels. The long, low greenhouse with double-bubble roof and three windows blends into the muscular rear end. The side mirrors are extended over the doors, just like in a typical sports coupe. And even the rear door handles help with aerodynamics. From a bird’s-eye view, the streamlined greenhouse gets smaller and chunkier as it goes back, giving it a really distinctive rear end. Another cool feature at the back is the wide diffuser in exposed carbon, which sweeps down deep on either side. It’s designed to keep the car stable at high speeds, just like AMG ONE.

Take a look at the rear end of this car. It’s got a really cool design with a sharp angle and six big red taillights. The lights and the central MBUX Fluid Light Panel (we’ll talk about that more later) are all framed by a long recess with conical sides. It makes the car look really deep and impressive. And guess what? There’s even an active spoiler/airbrake that’s built into the back.

Aerodynamics: an important factor for high performance, especially at high speeds

Fun fact, at 300 km/h, around 83 percent of the drive energy is used just to overcome drag. It shows how crucial efficient aerodynamics are in the high-performance segment.

The CONCEPT AMG GT XX is a real showcase of what’s technically possible. It’s got a sporty, flat shape, a sharply raked windscreen, a low-slung bonnet, angled side windows, and no rear windscreen.The aerodynamics continue right down to the underbody. They’ve got a specially designed contour that ensures perfect aerodynamic balance, meaning maximum downforce without compromising efficiency. It creates the Venturi effect, which reduces lift at the back without affecting the cd figure. This means a lower rear end and less need for a big rear spoiler. The clever aerodynamics offer a high level of handling stability at all speeds, even up to the top speed of over 360 km/h.

In all, the painstaking aerodynamic refinements reduce the drag coefficient and frontal area – which contributes to high-speed performance as well as to longer range at high speeds. Despite the wide high-performance tires, the drag coefficient is cd=0.198.

Aerodynamics also support other cooling functions

In addition to the big air vents in the front of the hood, the CONCEPT AMG GT XX has a clever passive cooling plate at the front of the underbody. It uses the airflow under the car to keep it cool. Another cool feature is the AIRPANEL system, which is also in the AMG GT series models and has been improved here. This system finds the perfect balance between cooling and reducing drag. It controls the airflow in several stages, depending on how cool you want it to be. The louvers are hidden behind the air intake in the front bumper, and they’re usually closed to reduce drag and direct air towards the underbody. But when the temperature at certain parts of the car gets too high and you need extra cooling, the louvers open in multiple stages to let the cool air flow to the heat exchangers.

Interior design: purist cockpit with exposed technology

Step inside the CONCEPT AMG GT XX, and you’ll be transported to a world of pure racing car elegance. The interior is bathed in a deep, rich black, making the silver and orange accents pop like stars in the night sky. It’s a visual feast and the materials used are top-notch, with textures that are as visually stunning as they are tactile. You’ll feel like you’re driving a piece of art. And let’s not forget the body structures and interior components inspired by high-voltage cables.. a nod to AMG’s motorsport roots. The cockpit is designed with a purist focus on driving, featuring two integrated screens that are perfectly positioned for maximum visibility. The 10.25-inch instrument cluster and the (14-inch multimedia touchscreen are ergonomically angled towards the driver, ensuring a comfortable and immersive driving experience.

The interior features exposed extrusions of the body-in-white around the centre console, with illuminated orange pipes, evoking the appearance of high-voltage cables. The centre console design incorporates the AMG coat of arms. The CONCEPT AMG GT XX showcases its top electric performance with high-tech features machined from solid metal and illuminated. The instrument panel lacks cladding, resembling a classic sports engine block with the AMG logo machined into it and matt-black shrink paint. The structural crossmember forms the upper part of the cockpit, integrating the instrument panel and ducting for fresh air and cabling. Vertical H-struts positioned centrally beneath it combine the cockpit substructure and centre console mount. Consistent implementation of the extrusion structure defines the overall design. Minimalist door claddings with an armrest extruding from it. Subtly backlit racing perforations in the door panels provide a contrasting effect.

The steering wheel is similar to the one in the AMG ONE, with its almost rectangular shape and two horizontal struts on either side inspired by motor racing. The steering wheel paddles serve to control recuperation. A display on the steering column uses different colour codes via eight LEDs to signal the state of charge (blue), recuperation and current performance (red). In addition, there are two round AMG steering wheel buttons that control other functions and display the options with coloured icons.

Emotional and intuitive MBUX

The user interface and the Mercedes-Benz User Experience (MBUX) in the CONCEPT AMG GT XX is based on the in-house Mercedes-Benz Operating System (MB.OS). The deeply integrated chip-to-cloud architecture networks and controls all domains and functions. For the CONCEPT AMG GT XX, the UI/UX design team in Sindelfingen programmed an exclusive interface that shows the highlights of the electric drive system, including the High Performance Electric Battery as a video animation on the multimedia display.

To save weight, the individually formed carbon-fibre bucket seats in the rear, including the cushions, are completely integrated into the car’s rear bulkhead. The roof has no headliner, which saves weight and exposes the carbon-fibre structure. The door panels with lightweight pipes and orange closing loops complete the innovative and sporty overall look. The chequered flag design of the colour-backlit fabric is a further reference to motorsport. The fastening points on the doors are clad with small buttons of machined aluminium. In a neat finishing detail, they display the AMG coat of arms and are accented with the exterior paint colour. The floor covering is made of 100-percent recycled materials.

Revolutionary drivetrain: high-performance axial flux motor and a new kind of battery technology

AMG performance tradition continues and the team at Affalterbach are carry forwarding the same to EV’s with the CONCEPT AMG GT XX, which introduces a revolutionary drive technology in the form of the innovative axial flux motor. Its technological underpinnings were originally developed by British electric motor specialist YASA – a 100- precent subsidiary of Mercedes-Benz AG. For its application in the CONCEPT AMG GT XX and subsequently in series production, the concept was taken to a whole new level of performance. This was achieved in a collaboration between Mercedes-AMG and the technology experts from YASA. AMG team also developed the software for the operating strategy, which optimally utilizes the high performance of the engines in the technology carrier. The innovative electric motors enable high power from an extremely compact package and enter series production at Mercedes-AMG in 2026.

CONCEPT AMG GT XX has an incredible power output of over 1,000 kW, which means it can reach speeds of over 360 km/h! And guess what? The new high-performance battery and three axial flux motors take it to a whole new level, especially when it comes to continuous power. This means the CONCEPT AMG GT XX can push its limits repeatedly, delivering a level of continuous performance that was almost unheard of in the world of electric mobility until now. But that’s not all! The battery stays in an optimal temperature range even during continuous spirited driving, which means not only can it perform on the road, but it can also charge super fast. You can recharge it for about 400 kilometres of range (WLTP) in just five minutes, which is roughly the distance from Bangalore to Palakkad. And after the charging stops, it can deliver full power again, which is pretty remarkable.

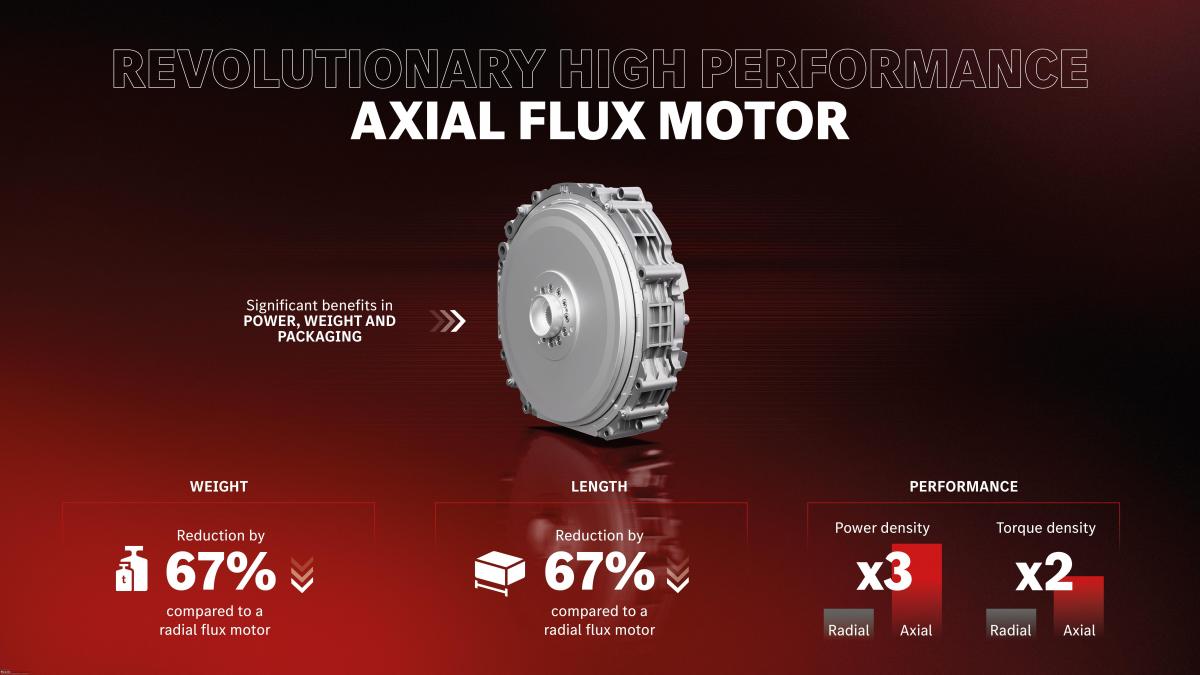

Significant benefits in power profile, weight and packagingAxial flux motors offer many benefits

They are significantly more compact, lighter and, above all, more powerful than conventional electric motors (radial flux motors). The power density of axial flux motors is around three times that of conventional electric motors. At the same time, motors are around two-thirds lighter and take up just one-third of the space, offering more freedom when it comes to drivetrain packaging. Compared with conventional electric motors, this system delivers a considerably higher sustained power output as well as higher torque. This means performance is not compromised even under extended, extreme runs. In an axial flux motor, the electromagnetic flux runs parallel to the motor’s axis of rotation. In a conventional electric motor, on the other hand, it runs perpendicular to the axis of rotation. In an axial flux motor, the large components are shaped like slim discs. The stator is positioned between two rotors on the left and right sides. This layout of stator and rotors enables optimum power transmission to the rotors through the electric field generated by the stator. In the CONCEPT AMG GT XX, this combination is barely nine centimetres wide. Each of the two motors at the rear is around just eight centimetres wide.

Compelling power: more than 1,000 kW peak output

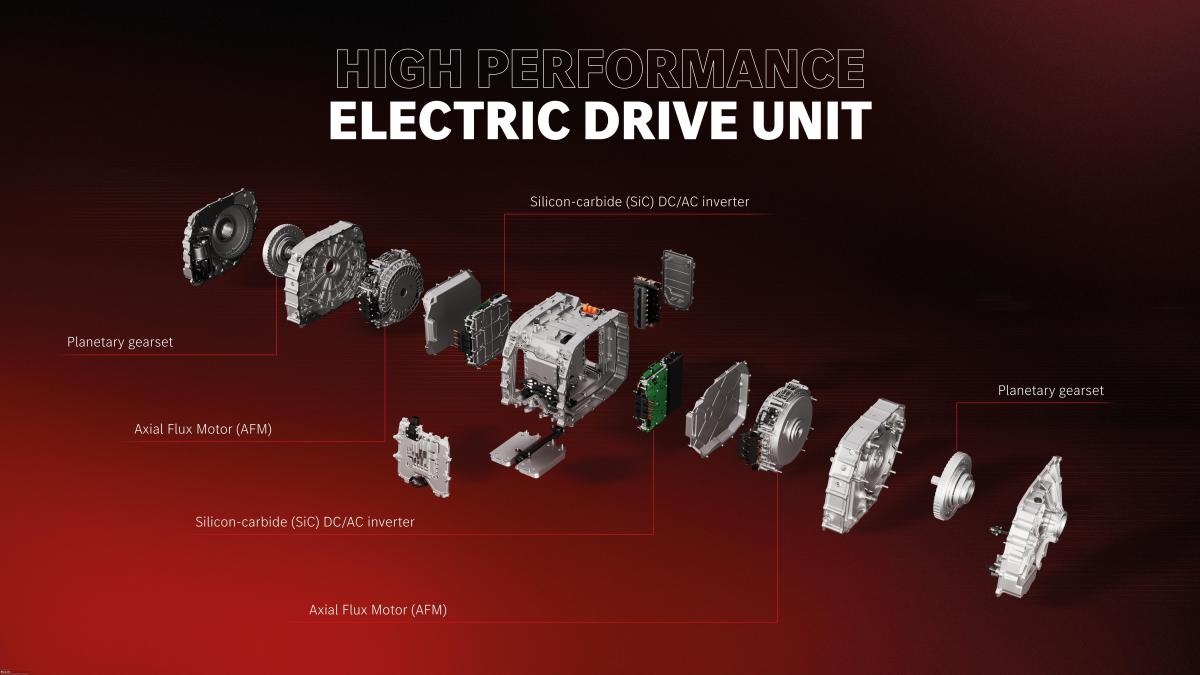

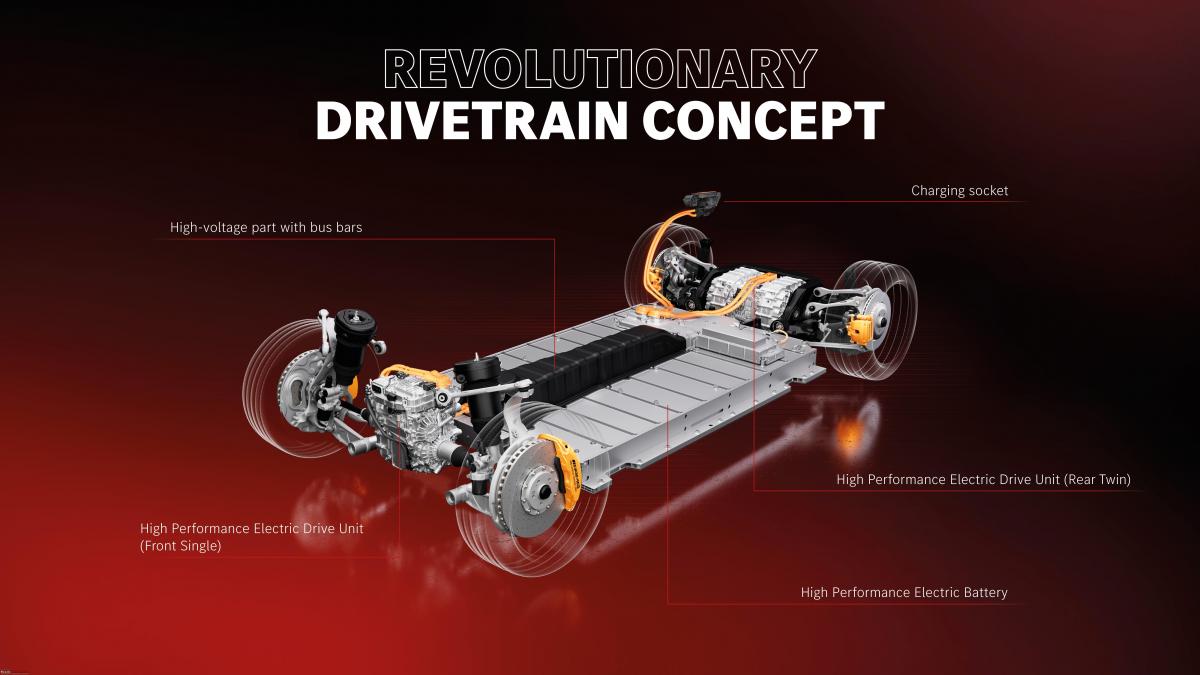

CONCEPT AMG GT XX has three electric motors that can produce over 1,000 kW, which is more than 1,360 horsepower! Can you imagine that? These motors are cleverly packed into two High Performance Electric Drive Units (HP.EDUs). One is at the front, and the other is at the back. The rear HP.EDU has two axial flux motors, each with a compact planetary gearset and an inverter all in one. They’re oil-cooled, which is great for keeping them running smoothly. And guess what? The pump control unit with hydraulic pumps and suction filters is also built into the HP.EDU to save even more space. The two inverters (one for each motor) are water-cooled. And here’s the best part: silicon carbide materials are used in these motors, which offer a bunch of benefits for demanding applications like high voltages, high currents, high temperatures, and high heat conductivity. Talk about cutting-edge technology!

Now, let’s talk about the front HP.EDU. It’s got one axial flux motor, a spur-gear transmission, and an inverter. This electric drive acts as a booster motor, kicking in when you need extra power or traction at the front wheels. But when you’re not using it, a Disconnect Unit (DCU) takes care of it and disconnects it. During acceleration and recuperation, the DCU stays on for optimal performance. And when you’re cruising along at a low load or coasting, it disengages again, reducing drag losses and increasing efficiency. Pretty cool, huh?

Innovative production processes for manufacturing the axial flux motor

The axial flux motors are produced at the Mercedes-Benz plant in the Marienfelde area of Berlin. It has been an important part of the global Mercedes-Benz Powertrain production network for decades and handles the production of various drive components. The manufacture of axial flux motors in Marienfelde involves around 100 production processes. Approximately 65 of these processes are new for Mercedes-Benz and 35 of them are world firsts. They include new forms of laser technology combined with innovative joining processes and artificial intelligence. These new production processes were developed largely in-house by Mercedes-Benz, and the innovations led to more than 30 patent applications.

Inspired by Formula 1, developed in Affalterbach: the High Performance Electric Battery

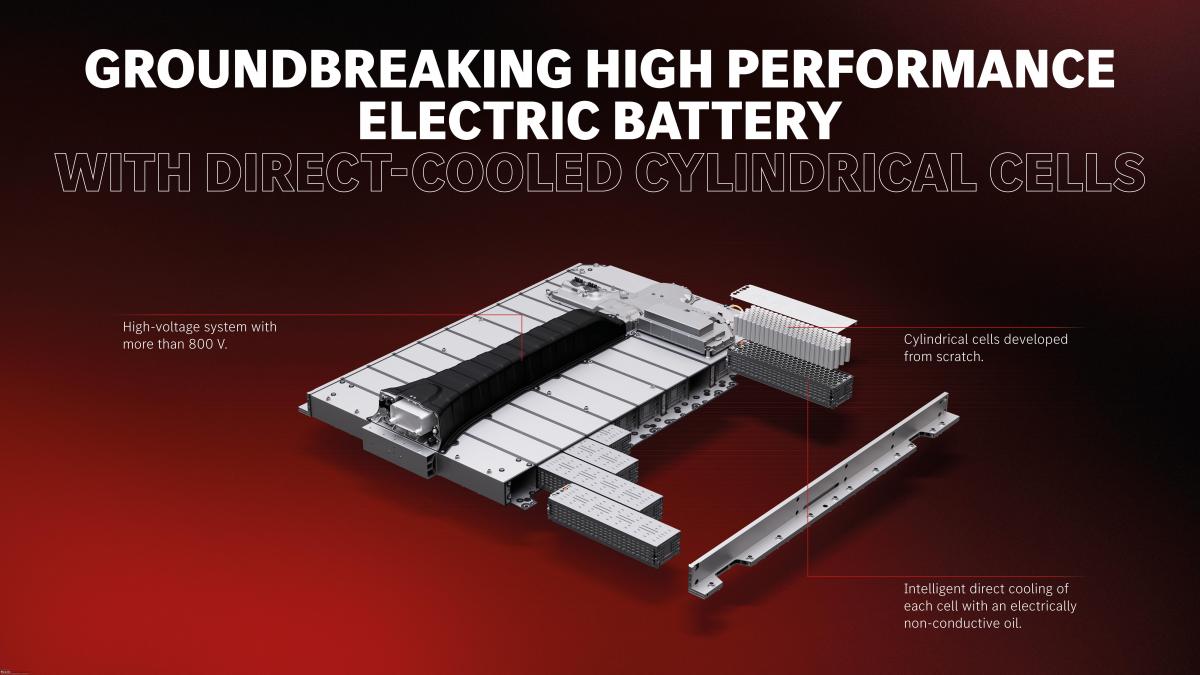

The high-voltage battery in the CONCEPT AMG GT XX is a completely new development. It benefits from all the experience from the AMG ONE and Formula 1 as well as the knowledge of engineers from Mercedes-AMG in Affalterbach and Mercedes-AMG High Performance Powertrains (HPP) in Brixworth (UK). The High Performance Electric Battery (HP.EB) delivers a high power output with exceptional repeatability, guaranteeing the vehicle’s outstanding overall performance. This is paired with rapid energy absorption and high power density. Contributing to the high system performance are three main aspects: new battery cell developments, direct cooling of the cells and high voltage.

New battery cells developed to meet exceptionally high performance demands

Centre stage is the completely new battery cell design, developed for exceptionally high performance. The CONCEPT AMG GT XX uses cylindrical cells that are remarkably tall and slim. This format delivers many benefits for cell cooling: The narrow diameter means the distance from the cell core to the casing is particularly small. This enables rapid dissipation of heat generated under load and ensures each individual cell is kept within the optimum temperature window. Also new is the laser-welded aluminium cell housing. It is lighter than the steel containers usually used and has considerably better electrical and heat conductivity. This offers benefits in the targeted thermal control of the cells – with faster cooling or heating on demand.

The cells use the full-tab configuration which means the entire surface of the cell tail is electrically and thermally connected to the pole. This enables a significant reduction in the cell’s internal resistance, which facilitates high charging and discharging power. Furthermore, full-tab battery cells are especially robust and also function reliably under demanding load conditions. A further innovation is the optimised operating window. The full-tab cells underwent detailed measurement and testing in advance using a special reference electrode and core temperature sensors. The data gathered was implemented in the software for the battery management system. This enables better modelling of cell behaviour and thus a significant increase of charging power at higher temperatures.

The cell chemistry was developed specifically for the CONCEPT AMG GT XX. It is based on NCMA (nickel//cobalt/manganese/aluminium) in the cathode and an anode with silicon content. It offers a combination of high energy density of 300 Wh/kg (740 Wh/l on cell level), powerful charging performance and long lifespan that is thus far unique. Overall, the combination of a tall, narrow cell format, aluminium housing, full-tab technology and NCMA chemistry lays the foundation for high performance within the individual battery cells, especially in terms of sustained power delivery.

Intelligent direct cooling of the battery cells

The individual cells are packaged into laser-welded plastic modules, whereby performance thinking is also to the fore. Direct cell cooling is integrated into the plastic modules to ensure optimum heat dissipation. A high-tech coolant based on an electrically non-conductive oil flows around each individual cell to maintain the optimum temperature. The coolant flows through coolant channels in the modules, which are optimised for equal cooling of all the cells. A special piping system ensures even distribution of the cooling oil. There are more than 3,000 cells in the CONCEPT AMG GT XX.

The lithium-ion energy storage unit has a high voltage of more than 800 volts, which also contributes to overall performance. The benefits of the high voltage are lower weight due to the lighter cabling, higher continuous power output and shorter battery charging times. Charge losses via the charging cable are also considerably less.

Temperature control for short charging times, minimal ageing and a long lifespan

Temperature control of the HP.EB is intelligently configured for different driving situations. Heating it to the optimum temperature window is fast and precise. Maximum power is delivered across a wide temperature band. The operating strategy is programmed to facilitate maximum performance from the battery, followed by a reduction in temperature through the direct cooling system. Intelligent heat management controls the temperature of the coolant for each cell module at precisely the pre-determined value as required (on-demand cooling). As a consequence, the battery retains its high power reserves, even during dynamic driving with frequent acceleration (battery discharged) and deceleration (battery charged via recuperation). This effective direct cooling in combination with the cell enables the high level of sustained power density.

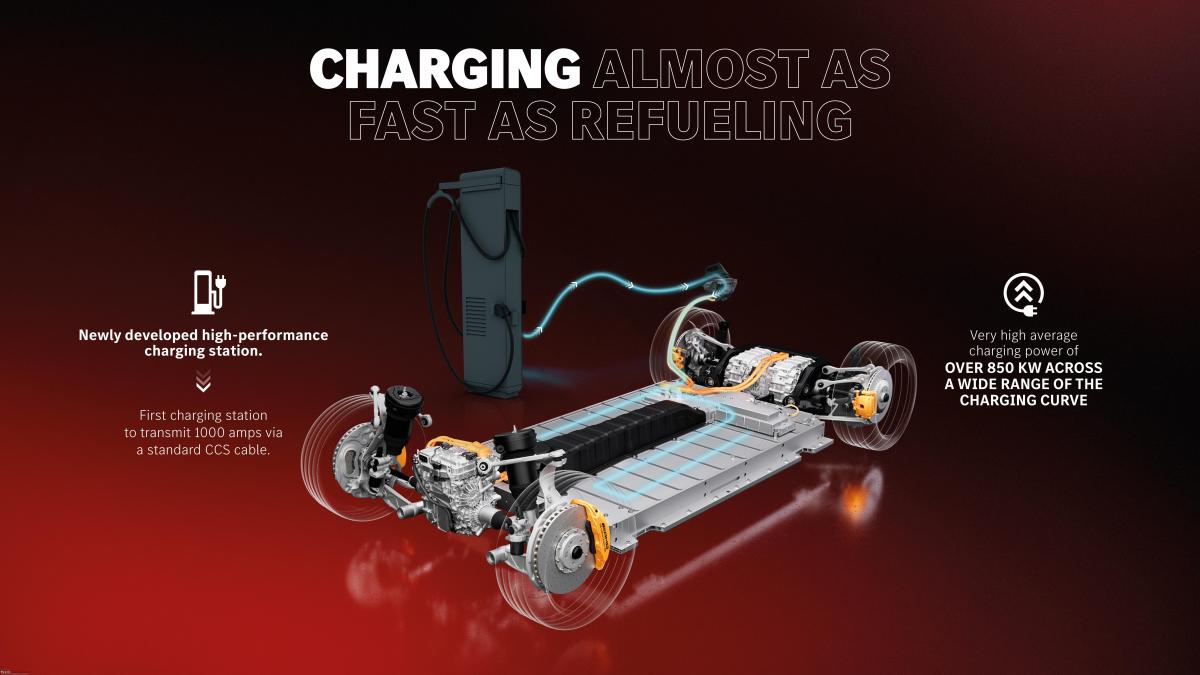

Charging almost as fast as refuelling

The charging performance likewise sets new benchmarks – again due to direct cooling. This pairs with optimised thermal management of the cells and power lines during charging. The CONCEPT AMG GT XX achieves a very high average charging power of more than 850 kW at 1000 amperes over a wide range of the charging curve.

To match the vehicle’s charging performance, the Mercede-Benz Charging Unit worked in close collaboration with its partner Alpitronic, the European market leader in high-power charging. Alpitronic has developed a prototype charging station. It is the first charging station able to transmit such a high current via a standard CCS cable. For the future series-production models, Mercedes-Benz will expand the infrastructure of its own Mercedes-Benz Charging Network with the next generation of high performance charging stations. Customers will benefit from extremely fast charging processes, where charging times differ only slightly from conventional refuelling with fuel.

Body-in-white plus battery housing: Safety is the number one priority

The body-in-white of the CONCEPT AMG GT XX is based on the new AMG.EA and is completely new. The intelligent material matrix consisting of aluminium, steel and fibre composite materials combines the exceptional stiffness that is a hallmark of AMG with low weight. Optimised material cross-sections and component design create space for the advanced technology and sophisticated running gear. The high-voltage battery is centrally integrated into the structure of the electric skateboard. Its protective housing encases the cell modules, all switch components and the Battery Management System (BMS), which is likewise an exclusive in-house development by AMG. Defined lateral load paths combine high torsional stiffness with low weight and form the basis for a high level of crash safety. The battery housing is part of the vehicle structure and integrated into the crash concept. Battery, high-voltage (HV) cabling and further HV components are configured and secured to fulfil high safety requirements.

Continue reading Jaggu’s experience for BHPian comments, insights and more information.