Nuclear fusion reactors rely on powerful superconducting magnets that must function under intense magnetic fields and at temperatures approaching absolute zero. These extreme conditions place extraordinary demands on the structural materials used, which must remain strong and stable despite the cold and stress.

Finding a material that can withstand both has challenged scientists for decades. Now, researchers in China have introduced CHSN01—China high-strength low-temperature steel No 1—a specially engineered alloy designed to meet these demands.

This year, it was used in the construction of what Chinese media reports claim to be the world’s first fusion nuclear power generation reactor, marking a significant milestone in materials science and fusion technology.

China’s fusion goals outpace ITER

More than a decade ago, Chinese scientists were already looking beyond the capabilities of international fusion projects. In 2011, a team developed the first viable material solution for fusion reactor magnets.

However, Li Laifeng, a researcher at the Chinese Academy of Sciences’ Technical Institute of Physics and Chemistry, remained cautious. He pointed out that while International Thermonuclear Experimental Reactor‘s (ITER) magnets were designed to operate at a maximum of 11.8 Tesla, future reactors would likely require even stronger magnetic fields and more advanced materials.

He also noted that the ITER being built in France was designed only for research and would not produce electricity, unlike China’s own planned fusion reactor, the South China Morning Post reported.

Hence, in 2017, Li presented a new material at the International Cryogenic Materials Conference in the U.S. However, many foreign experts were skeptical, believing that improving on the ITER-standard 316LN stainless steel—already designed for extreme fusion conditions—was virtually impossible and saw no need for a new approach.

By 2017, Chinese researchers had made progress by adding vanadium and adjusting carbon and nitrogen levels to improve the steel’s strength and toughness. Still, the material fell short of fusion-grade performance.

Renowned physicist played key role

The breakthrough did not come until 2020, when renowned physicist Zhao Zhongxian began attending the team’s meetings. A leading expert in cryogenic physics and winner of China’s top science award in 2017, Zhao had long stressed the importance of materials in superconducting technologies. His his involvement helped shift the project’s momentum at a critical time.

In 2021, China set demanding standards for its fusion reactor materials: 1,500 MPa yield strength and over 25% elongation at cryogenic temperatures. Fusion expert Li Jiangang called advanced steel development essential. That same year, Li Laifeng led the launch of a national research alliance to create a new domestic cryogenic steel, uniting institutes, companies, and welding specialists.

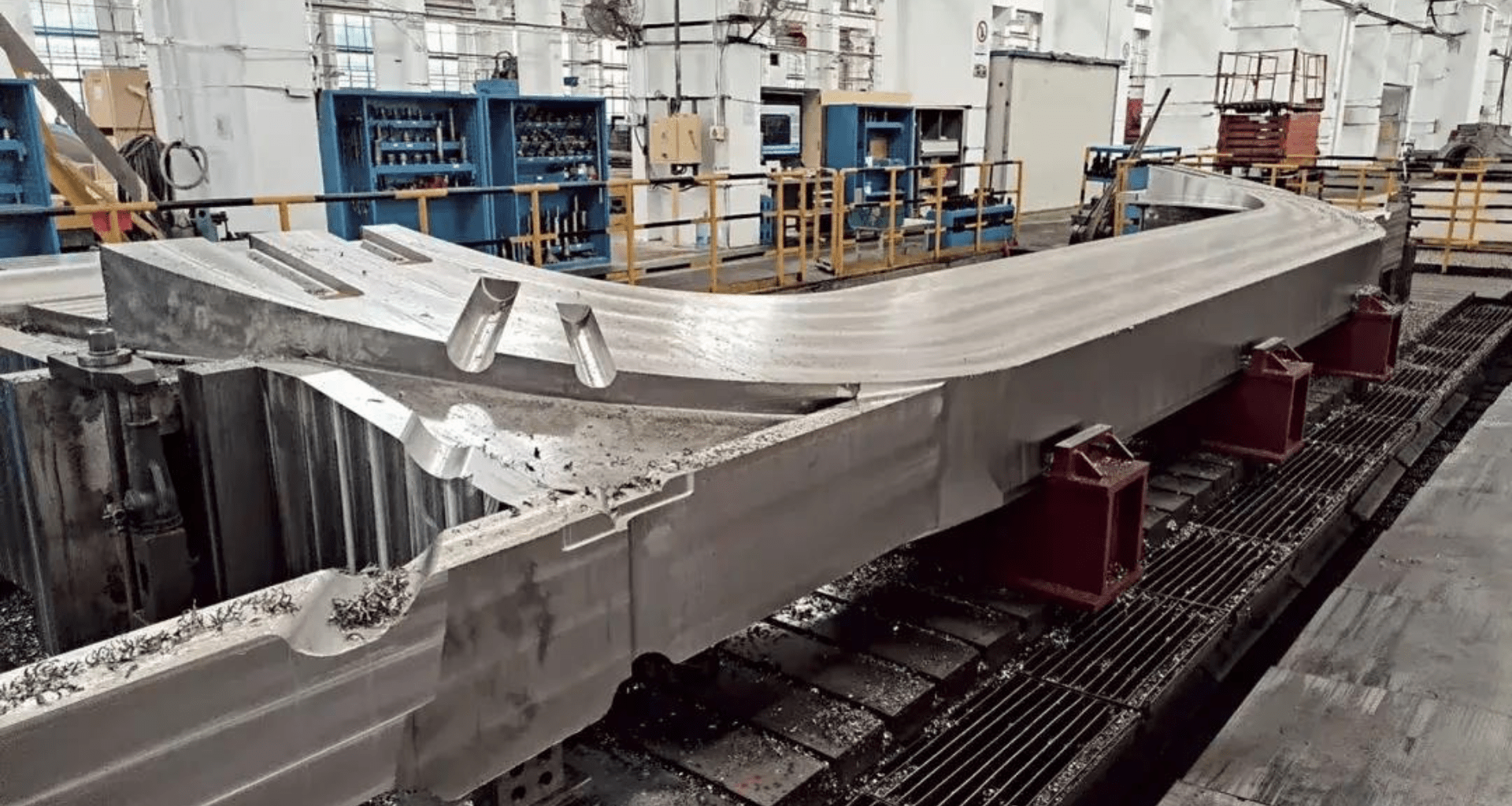

In August 2023, CHSN01 steel was confirmed to meet key standards, handling 20 Tesla magnetic fields and withstanding 1,300 MPa stress with high fatigue resistance. CHSN01 is now used in China’s BEST fusion reactor, which began assembly in May 2023 and aims for completion by 2027.

Of more than 6,000 tonnes of parts assembled for the reactor, 500 tonnes of conductor jackets are made from domestically produced CHSN01 steel, which China also plans to apply beyond fusion projects.