In-wheel motors are a certain kind of vehicle propulsion system that attunes the behaviour of a car more specifically with the steering. By placing motors by each wheel, a car is more responsive to steering when accelerating or slowing down, due to heightened control of the wheels. Finland have tested their state-of-the-art in wheel motors with extraordinary results.

Why is Finland using in-wheel motors instead of traditional ones?

The world is moving towards a more sustainable future, and the automotive industry is no different. For more environmentally friendly vehicles, alternative fuel options have become very popular. While hydrogen has been successfully powering cars and bikes, nothing has quite compared to the success of battery-operated vehicles.

Traditional electric vehicles have used motors placed in the same location as gas engines, allowing for the use of technology that already exists. These motors have been successful in their implementation but have resulted in a slight time lag for tire rotation. Finnish EV development platform Donut Lab has found a solution that aims to improve EVs tenfold—the in-wheel motor.

How is an in-wheel motor more effective?

Donut Lab is committed to redefining the future of mobility with their in-wheel motors, backed by a leading team of designers, engineers and industry experts. While there have already been some groundbreaking electric vehicles designed (like this one that blew the public away), Donut Lab’s in-wheel technology aims to avoid the lag time that other EVs have and change the game completely. According to Nissan Global:

“With an in-wheel motor, motors are installed close to each of the drive wheels and are moving the wheels through extremely small drive shafts. Since the drive shafts are so small, the time lag that arises with the rotation all but disappears, and motor power is transmitted to the wheels instantaneously, making it possible to control the wheels very precisely.”

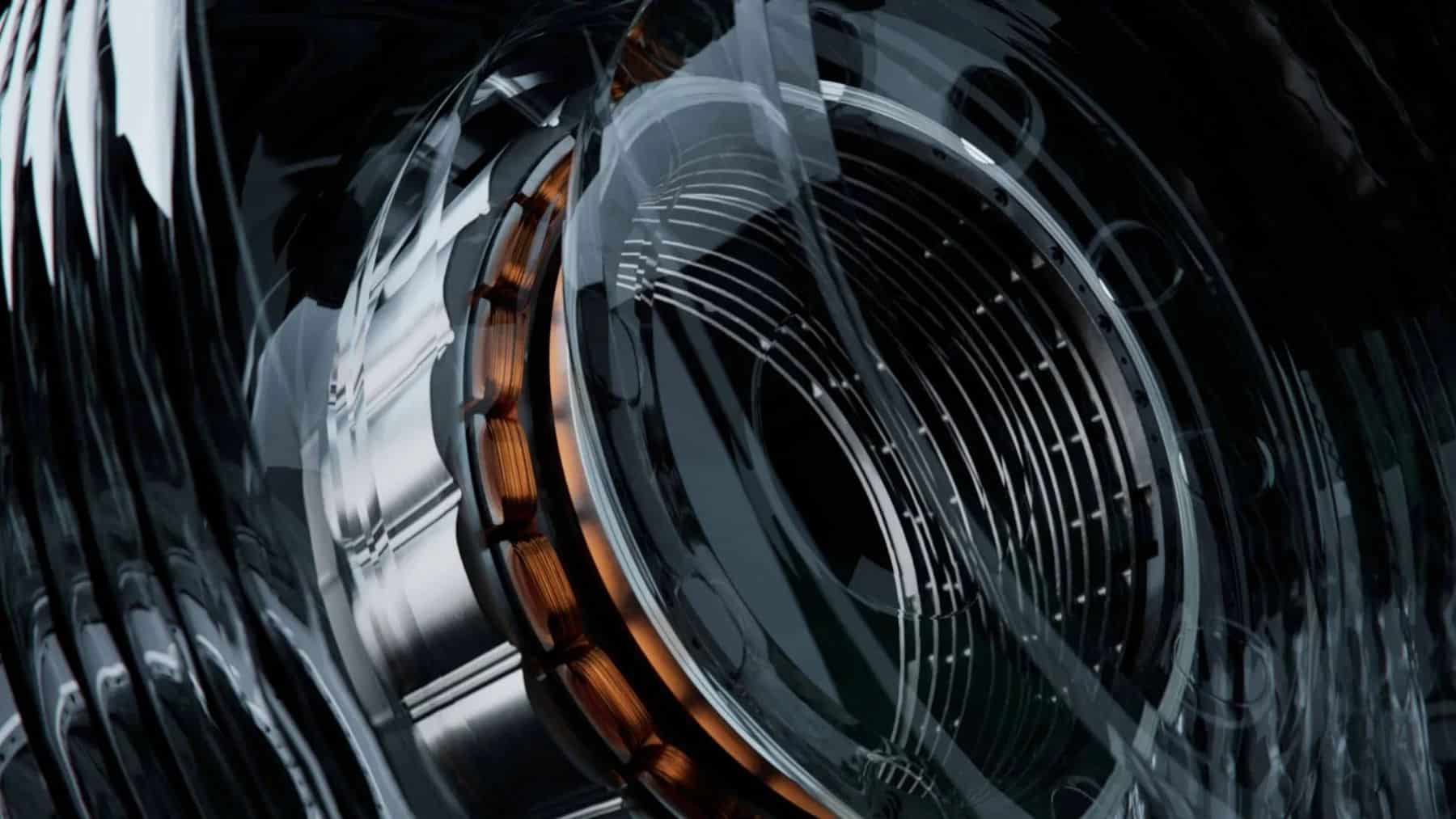

Donut Lab have produced a range of 5 in-wheel motors to power everything from drones to hyper cars, using the reduced lag time to improve efficiency and performance of various machines.

A closer look at Donut Lab’s range of motors

Unveiled at the CES 2025, the most powerful tech event in the world, Donut Lab’s motor family showed impressive results. They exhibited motors for automotive vehicles, semi-trucks, motorcycles, scooters and drones.

The star of the show was their automotive motor, which weighs only 40kg and produces an impressive 630 kW of power, placing it amongst the top contenders in the world. This motor also produces 4,300Nm of torque which far surpassing its competitors.

According to a Donut Lab LinkedIn post, their motors are a gamechanger because of the:

“Direct drive: No power transmission, no compromises – just pure efficiency.

Unrivalled torque and power density: Lightweight design meets extraordinary performance.

Optimized for every application: From compact scooters to heavy-duty trucks and beyond.

Cost-effective innovation: Higher performance at lower cost and weight, transforming the EV industry.

For two-wheeled motorcycles, Donut Labs has exhibited a motor with 150kW of power in a mere 21kg motor. For electric scooters, their motor can produce almost 15kW, and to power drones, the company has a tiny motor of 120mm that generates 3kW of power and weighs only 1,500g.

While the EV industry might not be expanding as rapidly as experts once thought, with companies like this one moving back to gas, it is still forecast that by 2032, the electric transportation market will grow from $550 billion to $4.4 trillion. Donut Labs is ensuring they remain at the forefront of this expansion, with their in-wheel technology allowing vastly reduced weight and costs and saving space inside the various machines. With a greener future in mind, this company is working hard to produce motors that almost all industries can make use of and minimise companies and individuals’ carbon footprints as much as possible.