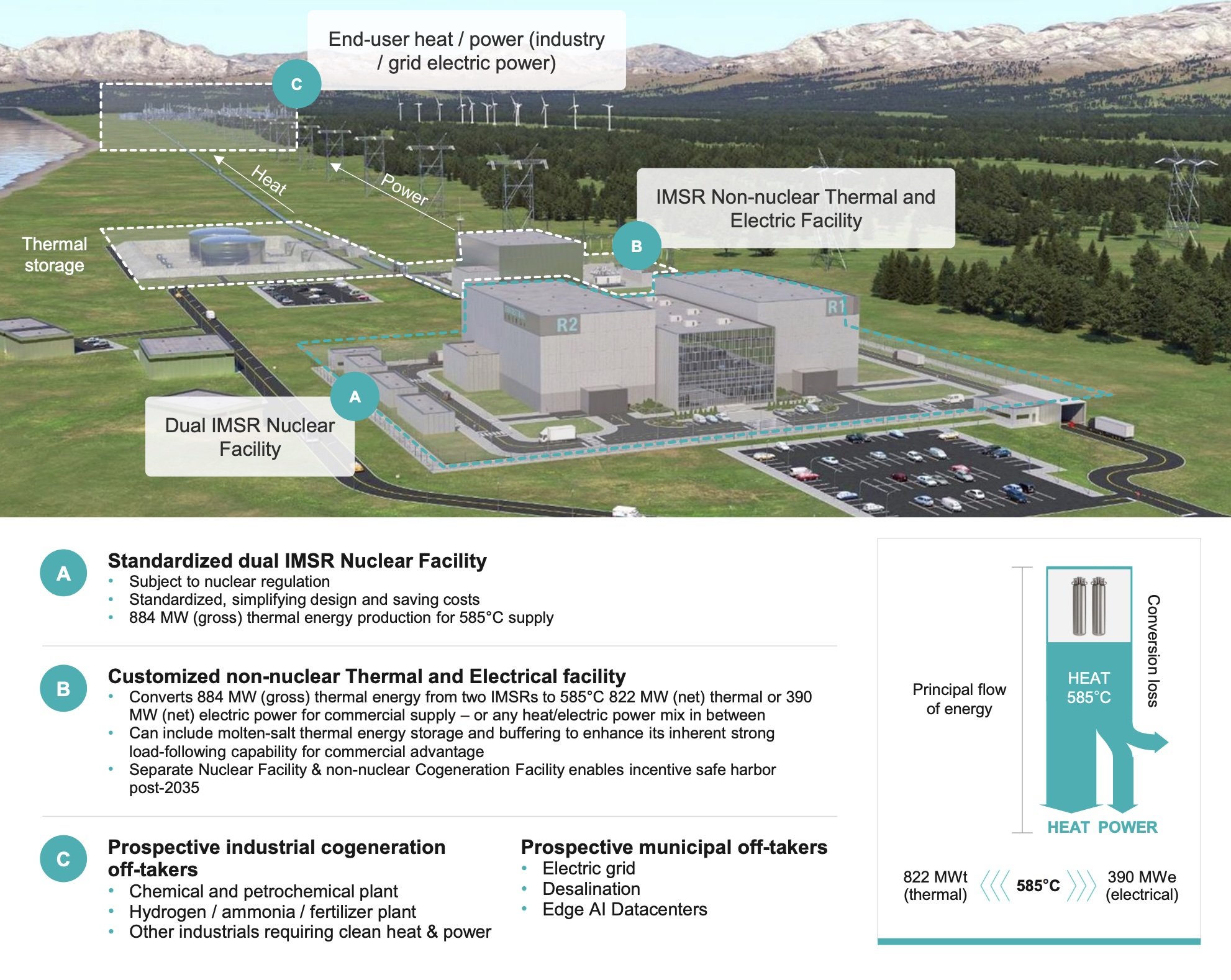

As the U.S. faces surging energy demand driven in part by data centers and artificial intelligence, Terrestrial Energy believes its integral molten salt reactor (IMSR) plant can deliver what traditional nuclear plants can’t.

That is 400 megawatts of clean nuclear power on just 25 acres located where it’s needed most, with a non-nuclear steam system deployable as soon as the full IMSR plant is developed.

The plant’s steam supply system can integrate with other forms of energy like battery storage or natural gas to drive turbines for electricity generation or to meet industrial direct heat needs.

“It gives you the ability to establish a nuclear power plant in a mode where it is generating electricity in under five years,” Terrestrial Energy CEO Simon Irish told Hart Energy. “That’s very relevant for the data center community because they … realize that AI is nothing more than a race to energy.”

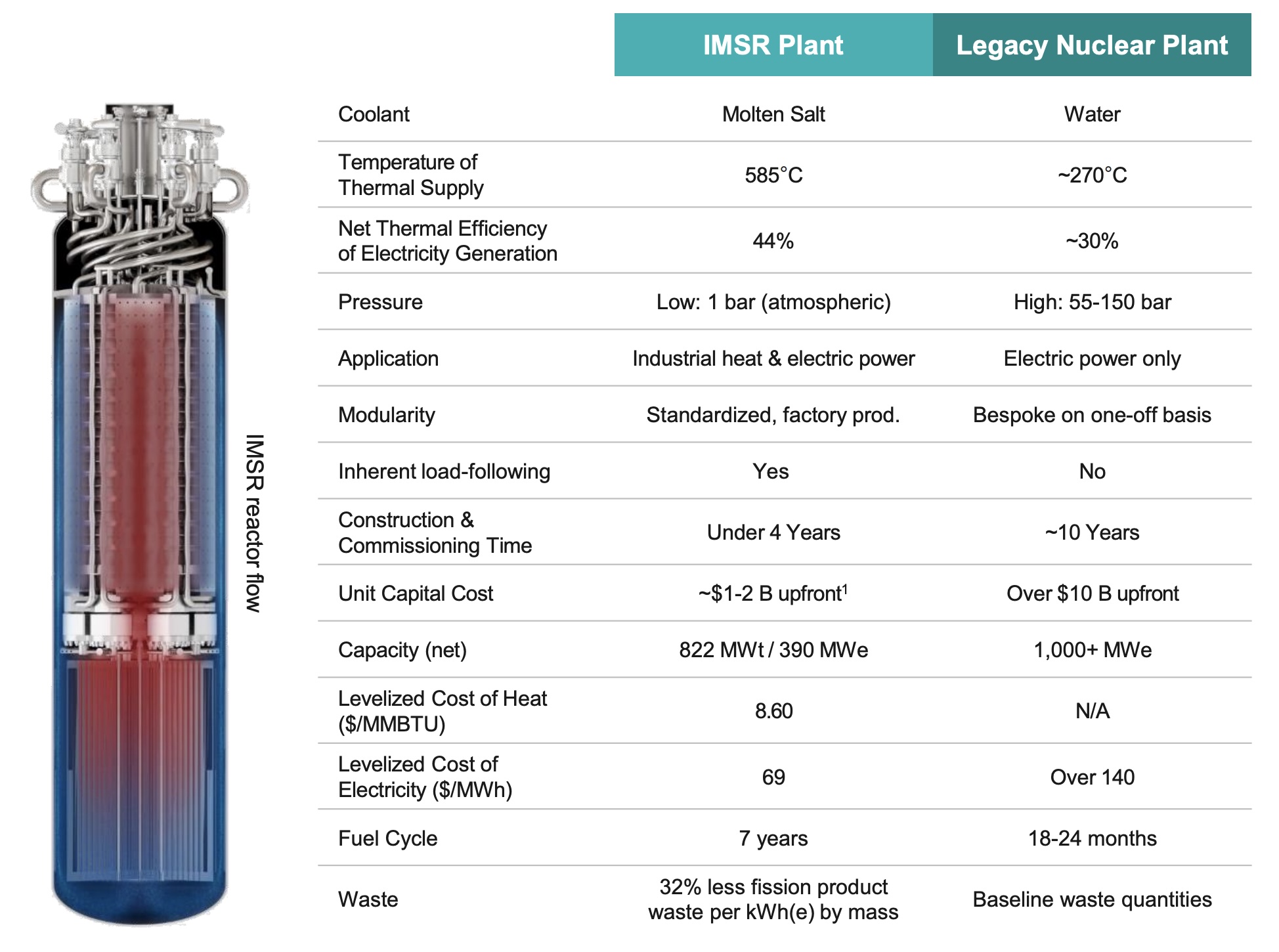

Terrestrial Energy is among the companies working to develop, license and construct small modular nuclear plants. Its IMSR is a Generation IV system using molten salt as both fuel and coolant. It delivers steam at 585 C, significantly hotter than traditional light water reactors, boosting turbine efficiency by nearly 50%. The company is advancing several IMSR-related initiatives, including regulatory and development work, but does not yet have an operational reactor. It aims to deploy its first commercial IMSR plants in the early 2030s.

The system operates at atmospheric pressure, removing the need for super-pressurized cooling, simplifying safety and engineering requirements. It’s also designed for 90% uptime with relatively simple maintenance protocols.

“That eases the engineering environment and creates a very different safety profile for your reactor,” Irish said.

Terrestrial IMSR Nuclear Facility (Source: Terrestrial Energy Investor Presentation)Poised to meet demand

Terrestrial IMSR Nuclear Facility (Source: Terrestrial Energy Investor Presentation)Poised to meet demand

The U.S. is counting on small modular reactors (SMRs) to help meet rising electricity demand. Unlike legacy nuclear plants, developers of SMRs offer baseload power with lower costs, faster deployment and a smaller footprint.

Though molten salt reactors have existed for decades, Terrestrial’s design is part of a new wave of advanced reactors seeking commercial viability.

Terrestrial was one of the 11 companies initially selected for the U.S. Department of Energy’s (DOE) Nuclear Reactor Pilot Program. The program seeks to streamline nuclear reactor testing and create a pathway to fast-track commercial licensing activities.

The goal is to achieve criticality—when fission events achieve a self-sustaining chain reaction— for at least three test reactors using the DOE authorization process by July 4, 2026.

“The pilot program gives us a different pathway and a potentially truncated pathway to construct, develop and operate a pilot reactor,” Irish said. He added the pilot reactor gives data essential for the company’s commercial license application.

Historically, nuclear projects have taken about 10 to 12 years to go from planning to operation. Irish believes this timeline can be shortened as regulators become more familiar with the technology and its advanced designs.

Designing for speed

IMSR Plant vs Nuclear Plant (Source: Terrestrial Energy Investor Presentation)

IMSR Plant vs Nuclear Plant (Source: Terrestrial Energy Investor Presentation)

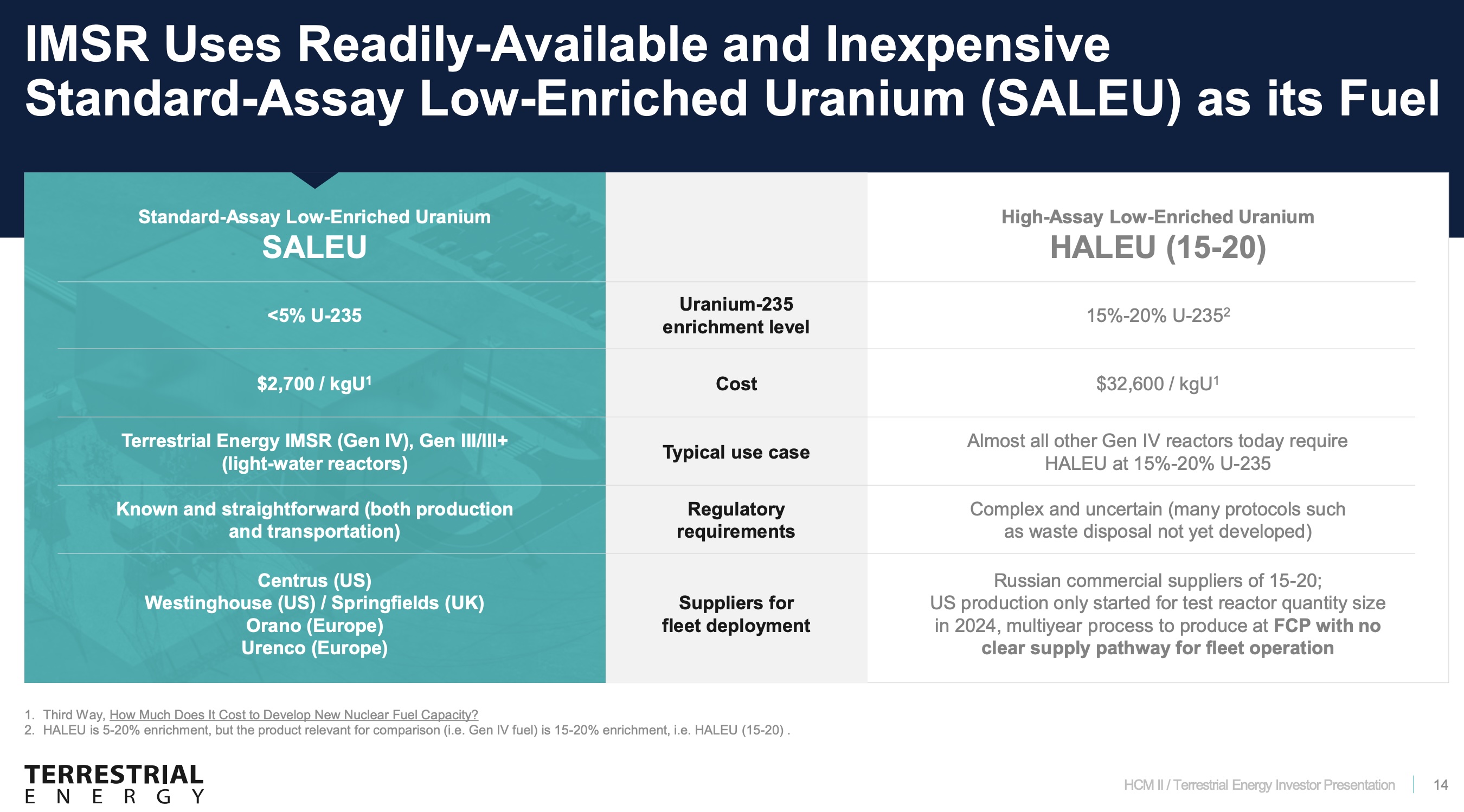

To accelerate deployment, Terrestrial is designing its IMSR system to work within the existing supply chain using standard low-enriched uranium—the same fuel used in conventional commercial nuclear power plants.

“You’re not looking [for] the perfect product. You’re looking [for] the product that meets a market need and is deployable fast,” Irish said. “To avoid that chicken and egg construction, you need to design to the capabilities of the existing supply chain.”

The company is focused on sourcing components from North America—and Western Europe—to strengthen its domestic position. That could be seen as an advantage in today’s policy landscape in the U.S.

“You don’t want to be saying I’m reaching halfway around the globe for key components,” Irish said. “What you want to be saying is I’m reaching to a different state, perhaps, for a different component.”

Partnering, looking ahead

Terrestrial is also focused on partnerships in its journey to deploying IMSR plants. It is one of four companies working with Texas A&M University to develop SMRs at its 2,400-acre RELLIS innovation campus in Bryan, Texas. In June, Terrestrial announced a partnership with Ameresco to support commercial deployment.

Rather than building and operating plants itself, Terrestrial plans to supply critical components—including the proprietary IMSR core unit—which is replaced every seven years in a sealed module, Irish said. It is targeting companies already capable of operating multiple plants.

Looking to the next three years, Irish said the company aims to demonstrate—through the development of its technology and project portfolio—a commercially compelling strategy. This, he said, will show that the company is capable of meeting deployment requirements the nation expects.

“What the nation needs is a technology that is affordable, equipped to deploy, has that supply chain to support fleet deployment, drive the steam turbine quickly, can be used in this double mode of thermal supply and electrical supply, and can do so near site,” Irish said.

(Source: Terrestrial Energy Investor Presentation)

(Source: Terrestrial Energy Investor Presentation)