Durst Group has celebrated the official launch of the P5 SMP, the new Super Multi-Pass solution, together with customers from around the world at its site in Lienz, Austria.

With this system, Durst introduces a printing solution distinguished by exceptional versatility and performance. The maximum production capacity reaches 5 million square metres per year.

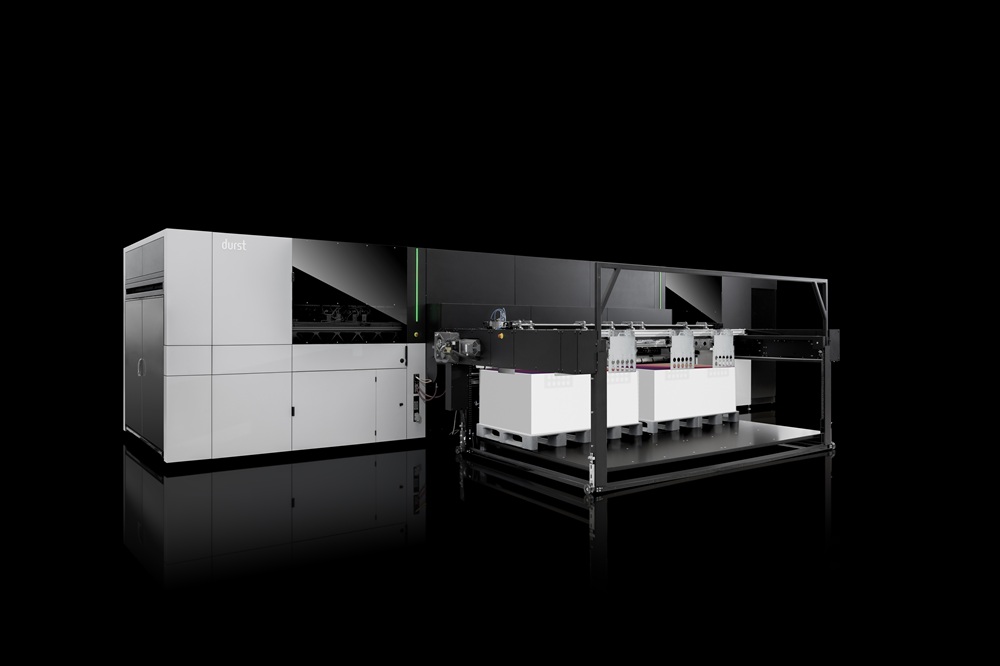

The P5 SMP is a hybrid LED multi-pass inkjet system with a printing width of 3.5 metres, designed for both board and roll printing. Based on the proven P5 platform, it provides a powerful alternative to conventional single-pass systems.

The P5 SMP was first unveiled a drupa 2024. For the field test, Durst partnered with ARIAN GmbH from Gleisdorf, Austria – a demanding collaborator that defines itself as a service provider for POS campaigns and acts as a global full-service provider.

In the Lienz Demo Center, visitors experienced live how quickly a complete material change can be performed on the P5 SMP

In the Lienz Demo Center, visitors experienced live how quickly a complete material change can be performed on the P5 SMPRobert Posch, chief production officer (CPO) at ARIAN GmbH, emphasised during the event that the P5 SMP has closed a production gap and impressed with its flexibility and reliability.

“We have tested over 200 materials in various formats on the P5 SMP. The short setup times and high level of automation help us manage this material mix in practice. With the P5 SMP, we’ve also expanded our production capacities and can respond to customer requests much faster – a decisive success factor in today’s sales environment,” said Posch.

Christoph Gamper, CEO and co-owner of the Durst Group, highlighted that together with ARIAN, Durst was able to fully exploit the potential of the P5 SMP in a real production environment, bringing the system to market readiness based on practical feedback.

“The response from both existing and potential customers to the P5 SMP has been overwhelming. We recorded additional sales during the event itself. The P5 SMP is a true game changer, elevating productivity and efficiency in digital large-format printing to a new level.”

In the Lienz Demo Center, visitors experienced live how quickly a complete material change can be performed on the P5 SMP. The system targets the sign and display, POP/POS, corrugated packaging and display, as well as industrial décor printing markets. The P5 SMP handles both roll and board materials up to 70mm thick. Currently, two formats can be loaded simultaneously; in its final stage, up to four formats will be possible.

Another highlight is the “DSA – Digital Substrate Alignment” system, providing precise digital image registration with an accuracy of ±0.25 mm. This feature is particularly valuable for double-sided printing, ensuring perfect front-to-back alignment and accurate registration forguillotine and die-cut processes.

Additionally, the “Automated Corrugated System” ensures high production safety, especially in corrugated printing. The material is continuously and automatically kept flat, preventing edge lifting and reliably avoiding material collisions.

Depending on the application, the P5 SMP can control up to 10 colour channels – for example, to extend the colour gamut with process colours (orange and violet), use light colours for smoother gradients, or apply white as a base for overprinting. The inks are cured using LED technology and print quality can be adjusted through resolution levels of 700 × 1200 dpi and 900 × 1200 dpi.

“To unlock the full potential of the P5 SMP, automation is essential. Durst offers comprehensive solutions here – from feeders with buffering, to alignment tables, and stackers that enable unattended operation throughout an entire shift,” said Andrea Riccardi, director of product management graphics and textile.

The maximum productivity of the P5 SMP is 1,940 m²/h or 340 boards per hour (format 3.2 × 1.6 meters). Even in the fully automated version, the required space is only about 160 m², a clear testament to its compact design. Furthermore, the P5 SMP is delivered with Durst

Workflow and Durst Analytics software packages – tools that continuously enhance production efficiency. Another advantage, Riccardi emphasised, is the low energy consumption of the LED solution, requiring only 35 kWh.

“In the B2B sector, investment security is a top priority. With the P5 XT concept, we offer a platform that evolves on every level – a commitment we have made to our customers. This applies to productivity, reliability, and the exploration of new application areas. Our systems grow with our customers’ needs and will continue to deliver top performance every day in the future,” Riccardi said.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter