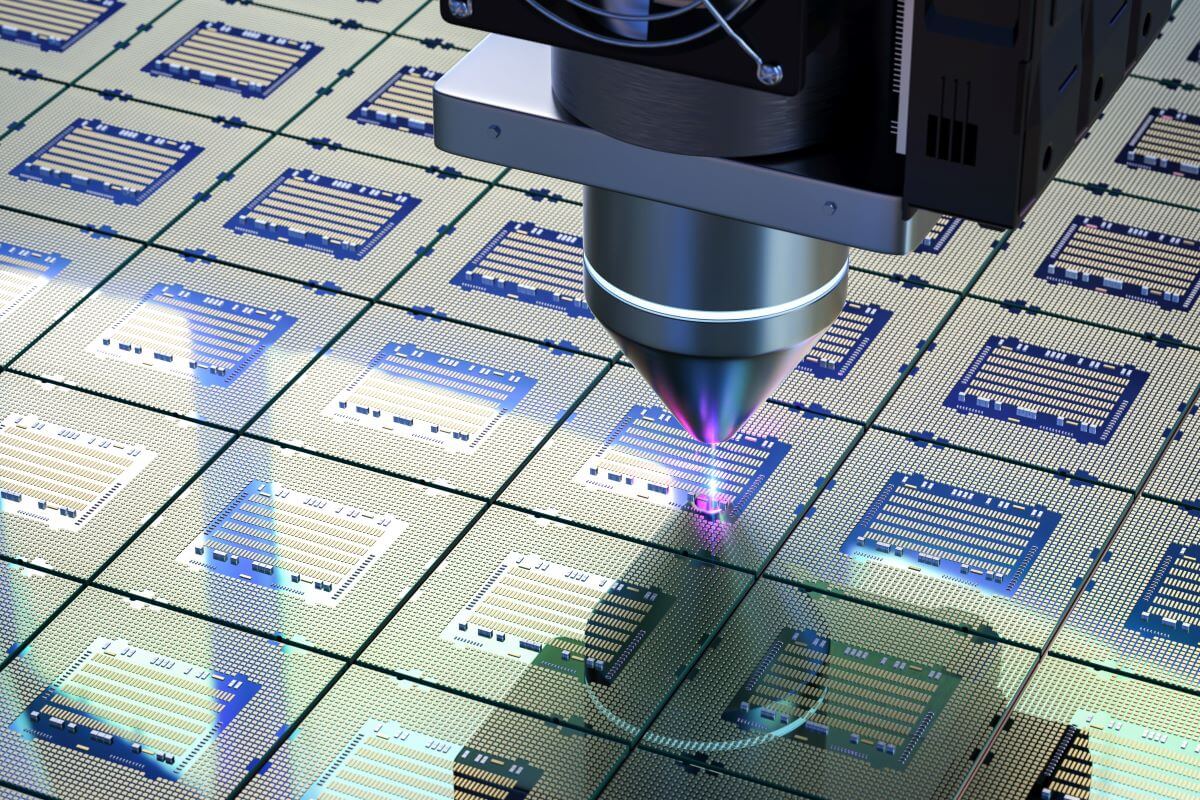

With a nod to Charles Dickens, Taiwan’s Semiconductor Manufacturing Company (TSMC) and America’s Intel could be a “tale of two companies,” with a string of opposite characteristics but a mutual stake in the Trump administration’s still-fluid tariff regime. Both also use the most recent models of a fabrication system (commonly called a “fab”) made only by a Dutch company, ASML, though only recently in the case of Intel. Fabs require a constant flow of specialized tools, components, and hundreds of dopes, chemicals, and purified gases. Most of these expendables are made in Japan, South Korea, and China, and could become subject to tariffs. Whatever form the administration’s still-changing tariff regime takes will have significant impact on the companies’ bottom lines and the future of U.S. semiconductor manufacturing.

TSMC is by far the world’s largest and most technologically advanced fabricator of semiconductors, a position that was Intel’s two decades ago. In Taiwan, the company fabricates 92% of the world’s cutting-edge semiconductors under contract, mostly for American companies like Nvidia, Apple, Advanced Micro Devices (AMD), Google, and Qualcomm. In Phoenix, Arizona, TSMC and its growing cluster of late model fabs are leading the renewal of cutting-edge semiconductor manufacturing.

TSMC’s Origins and Close Ties to the U.S. Semiconductor Industry

TSMC was founded in 1997 by Dr. Morris Chang, a Chinese American engineer with three degrees from MIT, a PhD from Stanford, and three decades of experience in the U.S. semiconductor industry. With high-level government encouragement, funding from Taiwan’s National Development Fund (NDF), and valuable production technology IPR licenses from the Dutch electronics giant Philips, Chang pioneered the “pure play” semiconductor foundry model of fabricating other companies’ chip designs under contract.

TSMC did not “steal” the America chip manufacturing industry. For more than 30 years, as predicted by Intel’s CEO Gordon Moore in 1965, the number of transistors that could be crammed onto a thin fingernail-sized silicon chip grew exponentially, doubling roughly every two years with ever increasing power, speed, and energy efficiency.

In 1972, semiconductor chips had about 10 thousand transistors, but by 1997, when TSMC was founded as a contract manufacturer, the density of transistors on chips had risen to about 8 million. The transistor count crossed 1 billion in 2017 and 40 billion in 2019. Nvidia’s current RTX Pro 6000 GPU chip has 92.2 billion transistors.

By the late 90s, the constant need for companies with in-house foundries to upgrade their fabs for the next-generation chip had become so expensive that only the largest companies — Intel being the biggest — could afford to keep designing and manufacturing their chips in-house.

TSMC’s new contract foundry model gave chip companies the option to go “fabless” and focus on research and chip design, both of which had a higher rate of return on capital. Nvidia, founded in 1995 and still led by Jensen Huang, a Taiwanese American, might not exist except for TSMC. His company was close to bankruptcy in 1997 when Chang responded to a personal appeal to fabricate “on spec” a new chip design, the RIVA 128, one of the first high-performance graphics processing units (GPU) chips. The rest is history.

TSMC’s Role in the Bipartisan August 2022 CHIPS Act

In a suburb of Phoenix, Arizona, TSMC Arizona is building a cluster of three cutting-edge “fabs” that directly respond to the goal of Section 103 of the bipartisan August 2022 CHIPS and Science Act to promote the “production of semiconductors and equipment and material related to production of semiconductors”. Its operations in Arizona are incorporated as the TSMC Arizona.

It was the city of Phoenix, Arizona, not the U.S. government, that made the first move to reestablish cutting-edge semiconductor fabrication on American soil. In the summer of 2019, the mayor and economic development director of the city of Phoenix traveled to Taiwan to pitch the Greater Phoenix region to TSMC, by then the world’s dominant fabricator of advanced semiconductors. The Phoenix area was already a major center for semiconductor design and manufacturing companies, including Intel, ON Semiconductor (Onsemi), a successor to Motorola, NXP semiconductors, and specialized supply chain companies.

When both TSMC and the Taiwan government showed interest, a team headed by the first Trump administration’s Undersecretary of State Keith J. Krach, a former Chairman and CEO of DocuSign, followed up from Washington with high-level negotiations that constituted no less than a historical U.S. shift toward “tech diplomacy” with Taiwan.

On May 15, 2020, TSMC announced that it would invest $12 billion in a single fab near Phoenix that would produce by far the most advanced semiconductor ever produced on U.S. soil. During a September 2020 trip to work out details, Krach became the highest State Department official to visit Taiwan in 41 years.

Krach and his team informed TSMC that they were working to get government support to help cover incremental costs arising from building fabs in the United States. The semiconductor industry, Congress, and the executive branch were already in prolonged negotiations for what became the CHIPS and Science Act.

The act appropriated $52.7 billion to support increased domestic research and manufacturing of semiconductors, of which $39 billion was for direct awards to attract investment in cutting-edge chip manufacturing. Three-quarters of the CHIPS funds have been awarded to American companies, but CHIPs awards were not final until specific milestones had been certified in multiyear projects.

The Commerce Department awarded Intel $7.865 billion (final adjusted award) for sites in Chandler, Arizona, Hillsboro, Oregon, New Albany, Ohio, and Rio Rancho, New Mexico, with a planned total investment of more than $100 billion. Micron, the only domestic maker of memory chips, was awarded $6.14 billion in grants and up to $7.5 billion in loans for new advanced fabs in Clay, New York and Boise, Idaho.

TSMC received an award of $6.565 billion to build three leading-edge fabrication plants (fabs) in North Phoenix, Arizona, the first of which the company started on its own before the CHIPS Act was passed, with a total investment of $65 billion of its own capital. The three fabs were designed for progressively more advanced node technologies, starting with 5nm (later 4nm), 3nm, and 2nm M16 (1.6nm). The completion of the third fab has been advanced from 2030 to 2029, while the second fab is scheduled to be online in 2026-2027. Without TSMC’s decision to build the first fab in the Phoenix area, the reshoring of cutting-edge semiconductor manufacturing on U.S. soil would have required many years more to get off the ground.

Commerce also awarded Samsung, which already has a large semiconductor operation near Austin, Texas, $4.7 billion towards a minimum of over $17 billion to expand its existing production facilities. That project was previously behind schedule but has now increased its investment to $40 billion and reportedly has an order from Tesla for its next-generation AI chips.

More than 20 (mostly American) companies received awards tailored to broadening out the domestic supply chain. These included Amkor Technology (advanced chip packaging and testing, a close TSMC “back-end” manufacturing partner), Corning (UV Glass/High Purity Fused Silica Materials), and Applied Materials (Silicon-core substrate R&D) companies.

Two decades ago, Intel was riding high with its Pentium microprocessors and the exploding popularity of PCs. In 2000, during the dot.com bubble, Intel’s market value hit $495 billion, making it one of the world’s most valuable companies, but it failed to maintain its leadership. Among other factors, it allowed fabless Nvidia to dominate the new graphics processing units (GPUs) that facilitated gaming and multimedia applications. Later, Intel also turned down a deal to make microprocessor chips for Apple’s new iPhones.

During the period from 2014 to 2016, Intel declined to buy the new extreme ultraviolet (EUV) lithography system developed by ASML that quickly became essential to making the next generation of cutting-edge chips, including those required for iPhones, high-end telecommunications equipment, and AI.

The longer-term impact on Intel was nearly catastrophic. Without ASML’s EUV lithography system, Intel fell behind both TSMC and Samsung. Intel struggled for two years to make a next-generation 7nm chip using a previous generation ASML machine but eventually had to ask TSMC to carry out the most complicated steps with its own in-house process technology using its EUV system fabs.

In January 2021, Intel’s board appointed Pat Gesinger as CEO with the mission of turning the company around. After decades of cautious, conservative CEOs at Intel, Gesinger adopted what turned out to be an overly ambitious program of building new foundries and upgrading others that left a $90 billion hole in Intel’s capital. On July 23, 2020, when Intel announced that a new 7nm chip (now rebranded as Intel4) had a major defect and would be delayed six months, the company’s stock fell 16%. Six months became two years before Intel turned it over to TSMC to fabricate. Currently, TSMC is making the graphics processing part of Intel’s current Meteor Lake and future Arrow Lake “chiplets” (a kind of chip-on-chip assembly) using its cutting-edge 3nm processing node and advanced packaging.

Trying to make up for Intel’s past decision not to buy ASML’s EUV system, Gesinger bought two of AMSL’s latest HA (High Aperture) EUV lithography systems that currently cost about $380 million each, even before TSMC had decided to buy them, with the goal of passing TCMC.

Intel had also received a $3.2 billion award from the CHIPS funds for a Secure Enclave Program administrated by the Department of Defense to expand trusted manufacturing of leading-edge semiconductors for military and intelligence requirements. The award generated congressional criticism that it represented a “classified handout” that shouldn’t have been taken from the CHIPs account. While Intel said that the award reflected confidence in its latest chip under development that would compete with TSMC’s 2nm chip and was “on-track” for production in 2025, the company had cut 15% of its employees to resize and refocus after “disappointing” results for Q2 2024.

Overall, Intel stock declined from $68.3 in mid-2021 to $19.95 on August 7, 2025. It rose to $37.01 on October 16, after the Trump administration’s announcement that it would buy $9.9 billion of Intel’s common stock using $5.7 billion that had not been awarded from the CHIPS Act funds and $3.2 billion from a DoD national security Secure Enclave Program.

Tariffs, Real and Threatened

The futures of both TSMC and Intel and the reshoring of cutting-edge chip manufacturing on American soil continue to be affected by President Trump’s tariff policies. Broadly, the administration is using tariffs and the threat of tariffs to incentivize foreign investment in domestic manufacturing. Regarding large-scale investment in domestic manufacturing, the policy has been both aggressive and erratic to date.

The use of tariffs on imports of Chinese-made parts and components is a separate issue that has been heavily influenced by President Trump’s effort to negotiate a comprehensive trade agreement with Beijing. Currently, the combined rate is 70%. Many U.S. companies depend on Chinese components that are “mature” technology but are either not available from other sources, or if they are, at a much higher cost.

As for semiconductors and more high-end components from other countries, much depends on whether the president’s announcements about tariffs are set in stone or are bargaining moves. Thus far, the only tariff with permanence is the baseline 10% tariff, which is applied to nearly all imports, including devices containing semiconductors, but semiconductors themselves remain duty free.

President Trump has raised the possibility, most recently in early August, of applying very high tariffs, as much as 100%, to semiconductors imported from companies that do not establish manufacturing operations in the United States. On March 3, 2025, in a White House meeting with CC. Wei, TSMC’s CEO, the President said that the company would invest $100 billion for three additional fabs, two advanced chip packing plants, and a R&D center, amounting to the largest ever foreign investment in the United States. TSMC denied that their investment decision was made because the president’s claim that he had threatened the company with a 100% tariff if it failed to deliver.

Rather, TSMC said that the components of the additional investment had already been decided in response to high confidence in growing demand from Apple, Nvidia, AMD, and possibly other fabless American companies. They cited the seemingly insatiable demand for AI chips for use in data centers and advanced computing as the main driver.

TSMC’s investments so far have been the most significant advance towards the U.S. goal of self-sufficiency in cutting-edge semiconductors. The addition of three fabs, two advanced packing facilities, and the R&D center will help broaden the buildup of a domestic supply chain.

The main risks are the 30% (or more) higher costs for fabricating advanced chips in the United States and the diminishing possibility that the administration might go through with a significant tariff on foreign semiconductors, including Taiwan’s. So long as demand is growing, U.S. production will be accompanied by the continued import of millions, if not billions, of chips of all kinds.

Still, because the administration is using tariffs as much for revenue as an incentive for foreign companies to invest in U.S. manufacturing, there can be no certainty about future policies. A move back to tariffs on chips would change the financial calculations on existing and prospective foreign invested manufacturing facilities and raise the cost of American manufactured vehicles, appliances, and the products of other industries that rely on foreign chips. The vast majority of these are mature technology legacy chips that will probably always have to be imported from lower-cost producers, including China, Vietnam, and India.

A New or an Ersatz Industrial Policy?

U.S. industrial policy regarding semiconductors is likely to remain more “ersatz” and opportunistic, in contrast to the CHIPS Act plan, which is comprehensive and has specific priorities. On March 31, the President issued an executive order establishing the United States Investment Accelerator within the Department of Commerce that is intended to facilitate and accelerate investments above $1 billion. The CHIPS Program Office (CPO) has been transferred to the new organization. There is little information on its future under the Trump administration, except for the fulfillment of the awards that were in place as of January 31, 2025 and a mandate to renegotiate them downward, if possible, to get a “better deal for the American people.”

President Trump’s decision to allow Nvidia and AMD to export tuned-down AI chips to China if they pay the Treasury 15% is purely a revenue issue and the obverse of an industrial policy. The chips in question, Nvidia’s H20 and AMD’s MI308, were designed to meet the Commerce Department’s criteria for exporting to China without an export license, but permission had previously been withheld. While the chips are detuned from cutting-edge, they still can help China with a “paradoxical situation” of an excess of computational power “coupled with a shortage of chips that meet the current needs for inference and regulatory realities.” This raises questions about the new policy’s impact on U.S. strategy to stay ahead of China in AI.

The Issue of a “Trusted Foundry”

Global Foundries, a “pure play” contract fabricator like TSMC, faced the same issue as Intel when commercial cutting-edge chips rapidly reached 7nm. Both companies had decided not to order ASML’s next-generation $250 million EUV lithography systems. It dropped out of the race and focused on making 12nm and 14nm chips for which there was and still is strong demand.

The consequence was that the Department of Defense lost its sole “Trusted Foundry Program” partner and had to rely on TSMC and Samsung for 7nm, 5nm, and beyond, and specialized chips that should be made in a secure domestic environment. This urgent national security supply chain issue was of concern even before COVID and was a major driver of executive branch and Congressional support for what became the CHIPS Act.

This unresolved national security dilemma dovetailed with President Trump’s desire for an American flagship foundry that could produce state-of-the art chips. Unfortunately, it is still not clear when Intel will be able to produce chips at the necessary 5nm-2nm technology nodes.

While the Trump administration is determined that Intel’s Foundry Division succeeds, this is problematic for several reasons. The division is losing billions of dollars, with overall gross margins on capital in the mid-30s versus historical rates of 55%-60%. A fundamental problem is attracting foundry business from competitors like AMD while Intel also produces its own chips. Why should they change from TSMC?

But for the government’s acquisition of Intel’s stock and commitment to acquire more, if necessary, the future of Intel’s foundry division would be very uncertain. The key objective of the CHIPS Act was to build up a domestic capacity to produce advanced and cutting-edge semiconductors, which was the reason that Intel was originally awarded the $8.76 billion.

Intel’s CEO Pat Gesinger bought two of ASML’s latest fabs, the HA EUV lithography systems, even before TSMC felt the need to do so because of his ambition to catch up with and supplant the industry leader. That just one of these systems sells for $380 million contributed to Intel’s financial situation.

President Trump has left no doubt about his belief that the U.S. semiconductor industry must be American led. The president has talked of requiring a 1+1 balance of domestic production and imported semiconductors to avoid crippling tariffs. The administration’s investment of $8.9 billion for about 10% of Intel’s stock makes clear that the struggling company must be a significant part of that equation.

In mid-August 2025, when talk of a purchase of Intel’s common stock by the administration was in the news, Japan’s Softbank invested $2 billion in Intel stock. In mid-September, Nvidia, which has deep involvement in AI and the semiconductor industry, announced that it would invest $5 billion in Intel, with plans to collaborate on custom datacenters and products for PCs. The move is apparently aimed at reducing its now total dependence on TSMC.

Following a trip to Taiwan at the end of September, Commerce Secretary Howard Lutnick said in a press interview, “The idea that I pitched them [Taiwan] was let’s get to 50-50. We’re producing half, you’re producing half.” The Taiwan government and TSMC both reject this concept as diluting TSMC’s role and are increasingly wary of the Trump administration’s “America first” protectionism.

In the near term, at least, chip production in the United States will depend mostly on TSMC and its fabs in Arizona. Both construction and production are moving even faster than originally planned, and their order book is growing. Given the disparity of TSMC’s fabs in Taiwan and the United States, the balance is likely to be closer to 80-20, never 50-50. This underscores the importance of Intel, and especially the viability of its Foundry Division. Nvidia’s $5 billion investment is a good start, but many other American companies will have to become customers for the division to stabilize and become profitable.

As for tariffs, it appears that just making the effort to invest in production on U.S. soil may allow foreign chips tariff-free entry. The threat remains that tariffs on components and operational supplies may significantly raise the cost of domestic chip production, which is already estimated to be 30% — or more — higher than in TSMC’s fabs in Taiwan.