Automated visual quality control outperforms manual processes and has become standard across many industries and applications. However, to increase profitability and gain a competitive edge, it is not enough to simply sort out defective parts – their production must be prevented from the outset. A cloud-based platform can help achieve this by closing the loop between production parameters, quality control, and product quality.

Virtually no modern production facility today can operate without cameras and corresponding image processing systems. These monitor production processes, detect errors, and enable fully automated identification and rejection of parts that fail to meet specifications. This reliably prevents defective parts from entering subsequent production steps or reaching customers, which in the worst case can lead to complaints and damage the company’s reputation.

Harnessing the potential of data and preventing waste

“The potential of the data obtained through quality control is even greater than that of the inspection itself,” says Peter Droege, CEO of Maddox AI. The company automates visual quality control in production using AI technology. Depending on the setup, such systems for big data analysis in quality control can be connected to existing cameras or use its own camera systems adapted to the respective production processes. An industrial PC receives the image data and evaluates it with the help of artificial intelligence. “Compared to conventional systems, AI-based models are significantly better at detecting and classifying errors and deviations. They produce far fewer false-rejects because, unlike traditional rule-based methods, the models are not affected by factors such as changing lighting conditions or the reflective properties of materials,” says Droege.

With intelligent, AI-based data analysis, companies can go even further, he says. “It should be possible to eliminate waste entirely, if data is collected, combined and analyzed for ongoing process optimization.” This can be achieved, if companies process the data collected during quality control and combine it with production parameters such as temperature, pressure, tool IDs, etc. This provides a basis for identifying patterns, correlations, and other insights that can be used to continuously optimize production processes to improve product quality and ultimately increase production yield.

Combining production and quality parameters

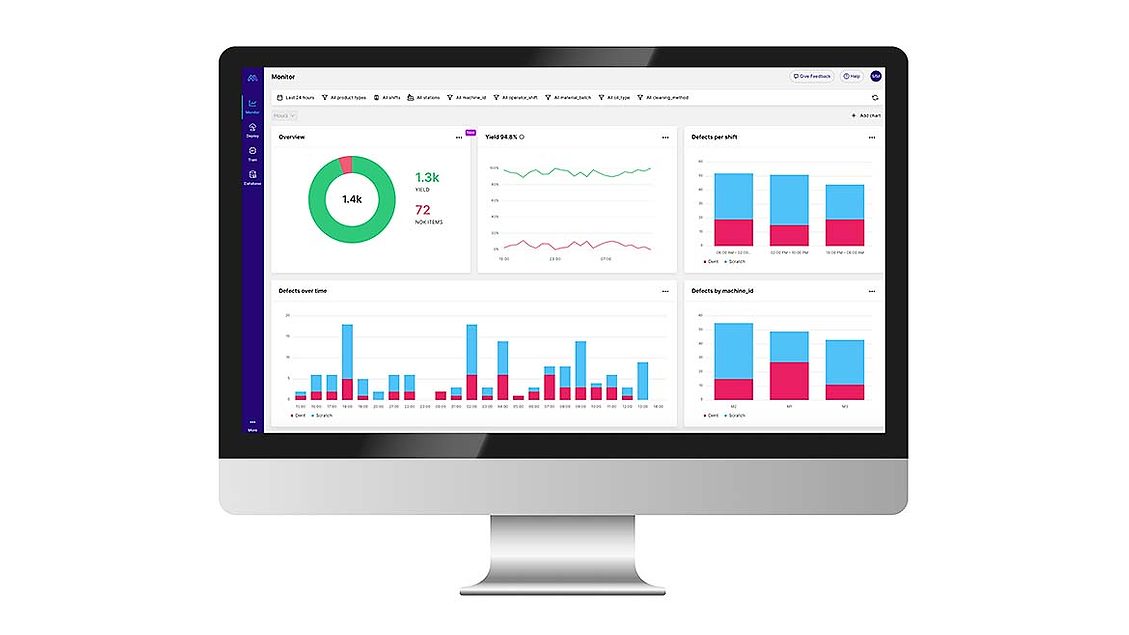

Key to leveraging all advantages of AI-powered quality control is the combination of quality data with production parameters in the cloud application. According to Droege, “Our AI inspection models run locally and do not require an internet connection. This is state-of-the art. But in addition, the data from quality control should be transferred to a cloud platform for further analysis, together with the process data. This data aggregation helps to identify possible correlations.” As a result, heat maps can be displayed, for example, in which the distribution of errors on manufactured components is visualized in real time. Views per machine and flexible filters by time period, shift, order, material, etc. provide further insights. These can reveal conclusions about the cause of the error, leading to improvements in the production process. This consistent digitization of the production process – from machine settings to the end product – enables a completely new understanding of processes and interrelationships. It helps reduce and prevent rejects over the long term.

Combining and analyzing data enables conclusions to be drawn about the causes of errors. This helps to continuously improve production processes.

Photo courtesy of AIMS Metrology

Droege and his team have a number of ideas for further expanding the capabilities of AI-based analysis of quality control and production data in the future. The CEO hints at one of these ideas. “In the future, it will be possible to not only show users which errors have been detected and how they might have occurred, but also make proactive suggestions as to what measures can be taken to avoid these errors.”

Production optimization across lines and locations

Another advantage of the digital solution: setting the optimal production parameters is no longer left to the experience and expertise of the operating personnel. Instead, the interactions between production data and quality are traceable and documented at all times. The findings can also be transferred between production lines within a plant as well as across locations and countries. This speeds up the setup of new production lines and thus also creates the basis for greater productivity and cost-effectiveness.

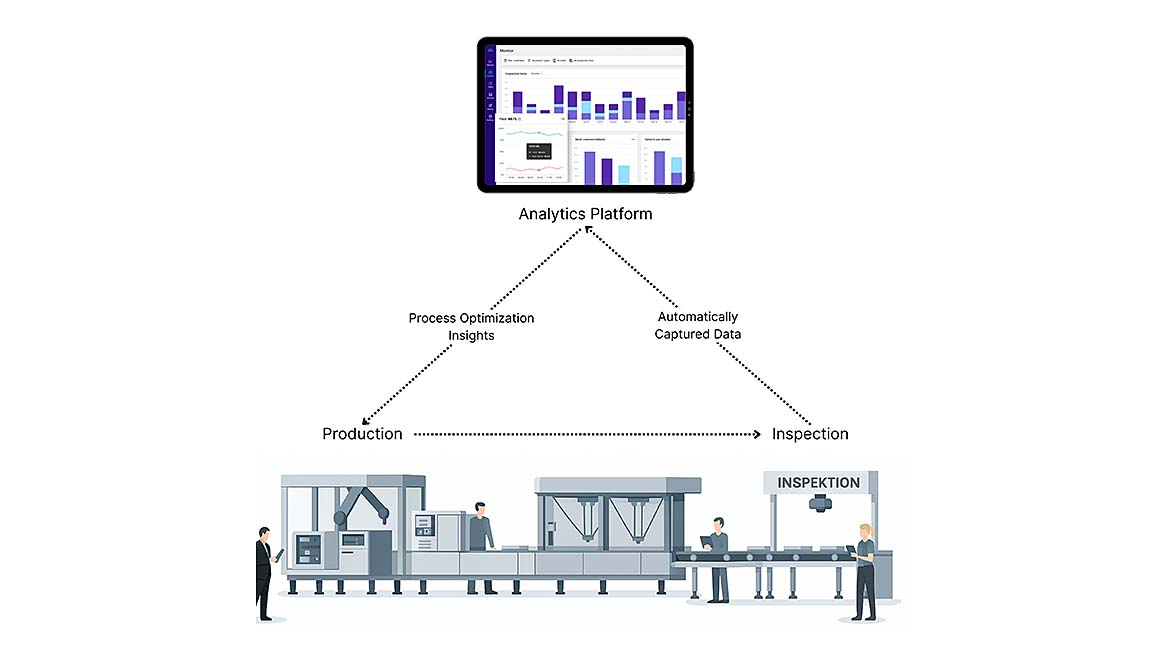

Production, quality, and process optimization in a closed loop

“The digitization of processes is increasingly becoming the norm,” says Droege. “With cloud-based and AI-powered platforms for data analysis, we enable data not only to be collected but also to be used profitably. We create a closed loop: from understanding production conditions via data, to product quality as a feedback signal, and back to optimizing production parameters. This creates a new understanding of production, and leads to less waste.” The more data the AI collects, the richer the understanding of production becomes, both for the AI and for engineers and operators applying these insights. Based on these insights, rules and measures can be derived for responding to production deviations during operation, in order to detect and avoid deviations even earlier in the future. To demonstrate secure cloud-based data transmission and processing to customers, solutions should ideally be SOC2 or ISO 27001-certified.

Cloud-based platforms turn production, inspection, and process optimization into a closed-loop system.

Image: Maddox AI

Rapid ROI, on many levels

The introduction of a hybrid model for quality assurance, which combines AI-based quality inspection with cloud-based analysis of process and quality data, delivers cost savings on several levels. This ensures a rapid return on investment: Fewer rejects increase productivity and reduce costs for re-sorting, repair, manual rework, and disposal. In addition, the AI models used enable better differentiation between genuine defects and pseudo-rejects or production variance. The central, cloud-based platform also makes insights transparent and comparable across plants and locations. This helps to transfer knowledge and avoid errors before they even occur. “Customers use cloud-based quality control platforms to improve their product quality and optimize processes,” says Droege. “In addition, product quality becomes more predictable and the effects of adjusting production parameters become understandable. This saves expensive experiments, time, and costs, to the benefit of productivity.”

READ MORE