Inside T1 Energy’s state-of-the-art G1_Dallas facility in Wilmer, employees are dressed in gray and yellow vests, stationed at different points along seven parallel half-mile-long manufacturing lines.

The staff works alongside robots — some of which blare “The Imperial March” from Star Wars at full volume as they cruise through the crisp, bright factory — and large, boxy machinery to make 20,000 solar panels a day.

The advanced technology manufacturing facility, about 20 miles south of downtown Dallas, opened last year and employs 1,200 people. Operations have ramped up to 24 hours a day.

“What can we say? We’re bullish on American solar,” Russell Gold, T1’s executive vice president for strategic communications, told The Dallas Morning News in a recent email.

Production employees Raquel Sanchez Nino, left, and Kenia Landaverde check solar panels for framing imperfections at T1 Energy’s G1_Dallas manufacturing facility on Nov. 13, 2025, in Wilmer.

Angela Piazza

The company is investing $1 billion in the state of Texas and in domestic manufacturing, including G1 Dallas and its forthcoming G2_Austin, a 5-gigawatt solar cell manufacturing facility being constructed in Rockdale. The latter is expected to begin production later this year.

“Honestly, we couldn’t think of any other place we would rather be building right now,” Gold said. “Texas has got a great workforce, it’s got a great business environment and it’s got really good energy prices, which are all important.”

Nationwide, manufacturing has stumbled under the weight of macroeconomic headwinds like tariffs and stubborn inflation. Yet in North Texas, the sector has recently experienced a noticeable surge in domestic manufacturing, as other companies also place bets that the region — and state — can support these kinds of facilities and jobs at a rapid pace.

Some experts and manufacturers say the alternative energy industry has particularly acted as a catalyst for the uptick, as the region’s population continues to multiply and data centers move in to support the artificial intelligence boom.

Clean energy, building renaissance

Manufacturing in Texas isn’t new. It has led the nation as the No. 1 exporting state for 23 years in a row, accounting for more exports than California, New York and Louisiana combined, according to a U.S. Department of Commerce’s Bureau of Economic Analysis.

As of December 2024, Texas exports year to date totaled $455 billion, a 2% increase from 2023, and exports accounted for 17.3% of Texas GDP, according to the Texas Economic Development Corporation.

A manufacturing renaissance in the U.S. has been driven by a historic wave of investment in clean energy technologies like wind, solar and battery storage, according to a study published last May by American Clean Power.

MJ Shiao, the trade group’s vice president of supply chain and manufacturing, said the largely bipartisan push to reinvigorate domestic manufacturing came from the COVID pandemic, when global trade was disrupted and showed how fragile supply chains were. Then, he said, the Inflation Reduction Act of 2022 continued the momentum.

In the past couple years, American Clean Power tracked about 200 primary clean power component manufacturing facilities across the country. About 20 of those — a majority solar — are in Texas.

“A big driver of that is Texas being a clean energy hub with all the deployments of solar and wind and batteries that are already in Texas, that puts these facilities close to their customer base,” Shiao said.

Also driving the energy manufacturing wave are parts of the supply chains being completely absent from the U.S. That prompted companies to start their manufacturing businesses domestically with the end product, like a solar panel or battery energy storage system, before adding upstream components like solar or battery cells.

“You do see these clusters building up in and around Dallas, and so that’s helped Texas emerge as one of these leaders in clean energy manufacturing,” Shiao said.

‘North Texas checks a lot of the boxes’

In Mesquite last summer, Chinese manufacturer Hithium opened its first U.S.-based manufacturing facility.

The nearly half-million square-foot plant East of Dallas is producing complete battery energy storage systems, as well as battery modules and components.

Like the other manufacturing facilities, Hithium’s plants have high-level technology with artificial intelligence and robotics.

The facility was at about 60% production with 160 employees, according to James Boswell, Hithium VP for North America operations, who spoke during a panel discussion at The Intersolar & Energy Storage North America Texas conference in November.

“I’ve built many factories in my career in the U.S., and this was probably the smoothest, fastest, most supportive and complex factory situation that I’ve been a part of,” Boswell said. “Texas has been very beneficial for Hithium and that’s why we chose it.”

Abdul El Baba, vice president of advanced technology at Gray Construction, which designed and built the facility, also praised the local community’s business-friendly environment, adding that North Texas is becoming a hub for smart manufacturing.

“North Texas checks a lot of the boxes: logistics, talent, incentive and just the growing demand. It’s quickly becoming like a magnet for clean energy investment,” El Baba said.

Companies “…want to build in the U.S. and that’s a key indicator that this is an emerging market.”

‘A bit of a bet’

Quentin Nelson holds a flat pack battery at UTD’s Batteries and Energy to Advance Commercialization and National Security (BEACONS), a 15,000-square-foot facility that opened earlier this year, at UTD Dallas, in Dallas, Texas, Wednesday, November 19, 2025

Anja Schlein

The University of Texas at Dallas is also embracing the uptick in clean energy manufacturing, opening its new Batteries and Energy to Advance Commercialization and National Security (or BEACONS) facility earlier this year.

“We’re placing a bit of a bet here,” Joseph Pancrazio, UTD’s vice president for research and innovation, said.

“ … It’s easy for academics to stay in the realm of theory and basic science, but we know our best stories are going to be those that support economic development, and we are placing a bet that energy storage is going to be an area for continued economic development not only for North Texas but for the country,” Pancrazio added.

Supported in part by a $30 million award from the U.S. Department of Defense and millions more in private capital, the 15,000-square-foot facility is designed to develop and commercialize new battery technologies and manufacturing processes, as well as train students for jobs in the energy storage industry. It’s set up to fast-track energy storage innovation and close supply-chain gaps.

On a recent afternoon, students in white coats and blue jackets buzzed around the different rooms of the facility, taking notes, weighing out samples of anode material and monitoring the battery-making machines.

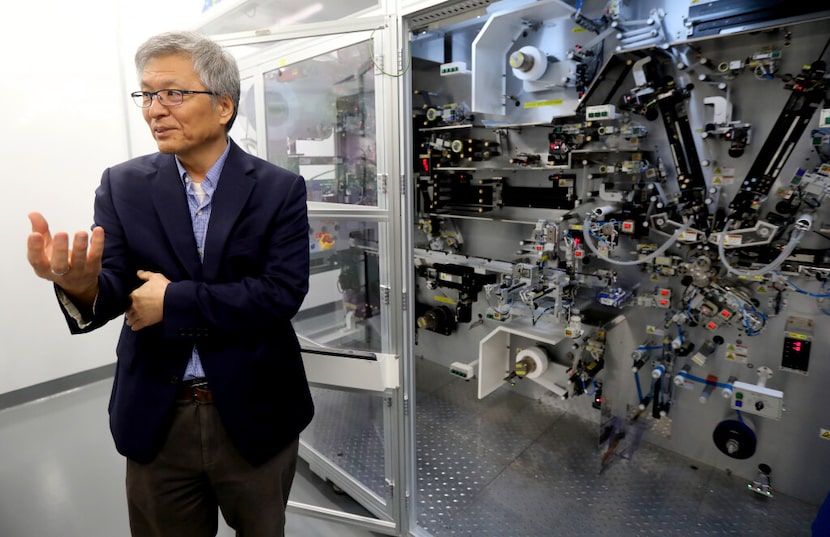

Dr. Kyeongjae Cho, professor of materials science and engineering, talks about the Winder Machine at UTD’s Batteries and Energy to Advance Commercialization and National Security (BEACONS) a 15,000-square-foot facility that opened earlier this year, at UTD Dallas, in Dallas, Texas, Wednesday, November 19, 2025.

Anja Schlein

BEACONS director Kyeongjae Cho stopped by a lab station and picked up a finished battery.

“What we are doing here is really reengaging manufacturing production, connecting with innovation and streamlining the whole process of novel batteries,” Cho said. “This is really leading the change the whole country is trying to achieve.”

Hopeful the upward trend will continue

The revival is a harbinger of the state’s broader manufacturing activity, which is accelerating, according to a recent survey by the Federal Reserve Bank of Dallas

Business executives responding to the Dallas Fed’s survey reported factory activity expanded at a markedly faster pace in November.

The production index, a key measure of state manufacturing conditions, rose 15 points to 20.5, signaling a notable increase in output growth. Expectations for the next six months also remained positive.

Tony Bennett, president and CEO of the Texas Association of Manufacturers, said Texas’ manufacturing renaissance is more about the transition to advanced and smart manufacturing.

“There have been so many advances in production and processing and now with AI coming along rapidly, you’re going to see a whole ‘nother element to manufacturing,” Bennett said.

Bennett is optimistic the upward trend in domestic production will continue and Texas is set to remain a leader with the odds stacked in its favor. Pluses include infrastructure that’s close to ports; highways and markets; a young workforce; strong education systems with technical colleges and higher education institutions; low energy costs, and business-friendly tax environment.

“You can see why folks are coming here,” he said.

This reporting is part of the Future of North Texas, a community-funded journalism initiative supported by the Commit Partnership, Communities Foundation of Texas, The Dallas Foundation, the Dallas Mavericks, the Dallas Regional Chamber, Deedie Rose, Lisa and Charles Siegel, the McCune-Losinger Family Fund, The Meadows Foundation, the Perot Foundation, the United Way of Metropolitan Dallas and the University of Texas at Dallas. The News retains full editorial control of this coverage.