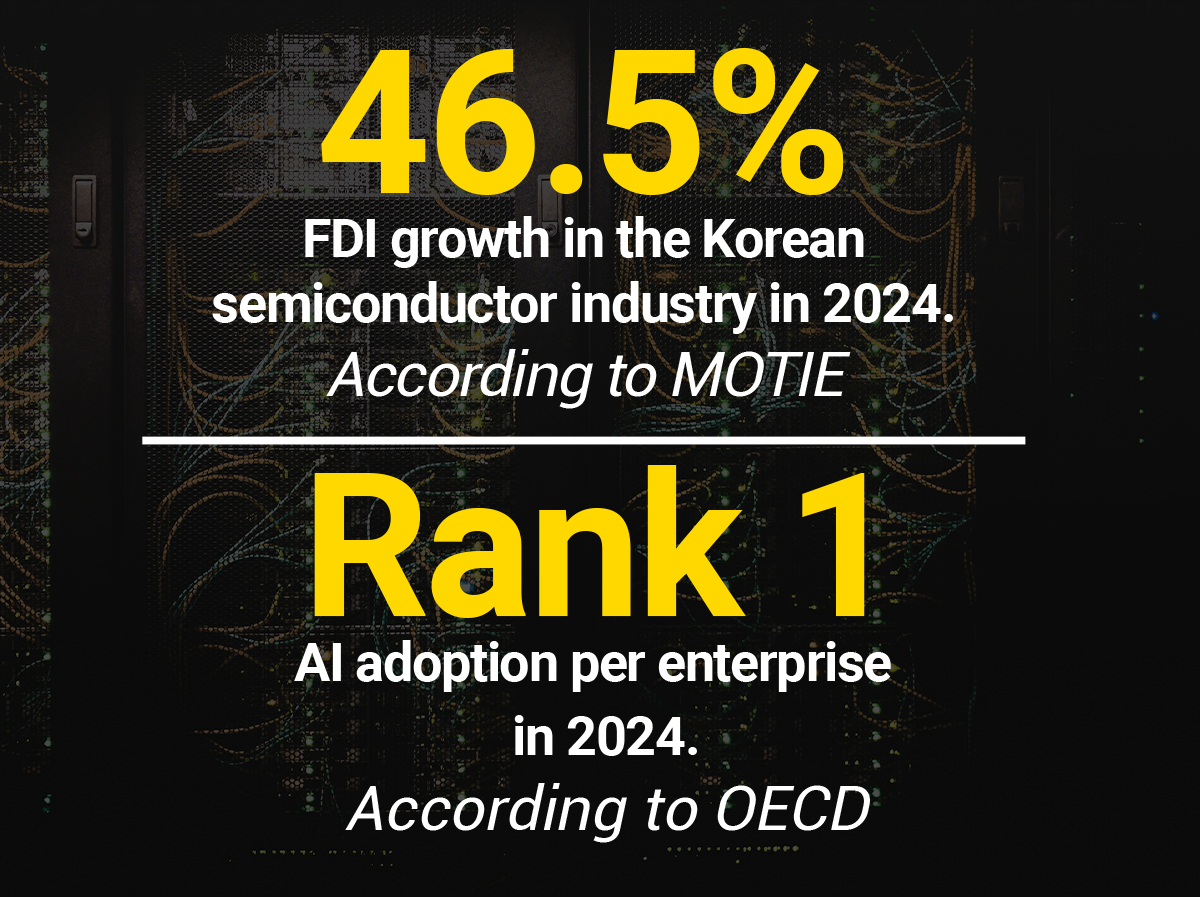

South Korea has evolved into a land of opportunity for investment in innovation. Last year, 2024, saw a record high in foreign direct investment, specifically in semiconductors, rising over 46 percent to $1.3 billion. Semiconductors remain the country’s flagship sector, as companies such as Samsung and SK continue to refine physics and engineering. Samsung Electronics intends to pioneer the mass production of the 2nm node, while SK Hynix was the first to deliver an HBM4 sample to NVIDIA’s GPUs early this year, thereby solidifying its leading position in HBM for AI accelerators.

South Korea is often wrongly overlooked as a center of innovation despite its central role in the development of critical technologies. Park Systems is a prime example of South Korea’s technological leadership, offering the world’s most advanced nanometrology solutions through its state-of-the-art atomic force microscopes (AFM). In the semiconductor and chip sectors, nanometrology technology is vital for both front-end and back-end processes. “These industries face persistent challenges in measuring increasingly small structures with traditional tools,” founder and CEO Sang-il Park says.

Source: MOTIE and OECD.

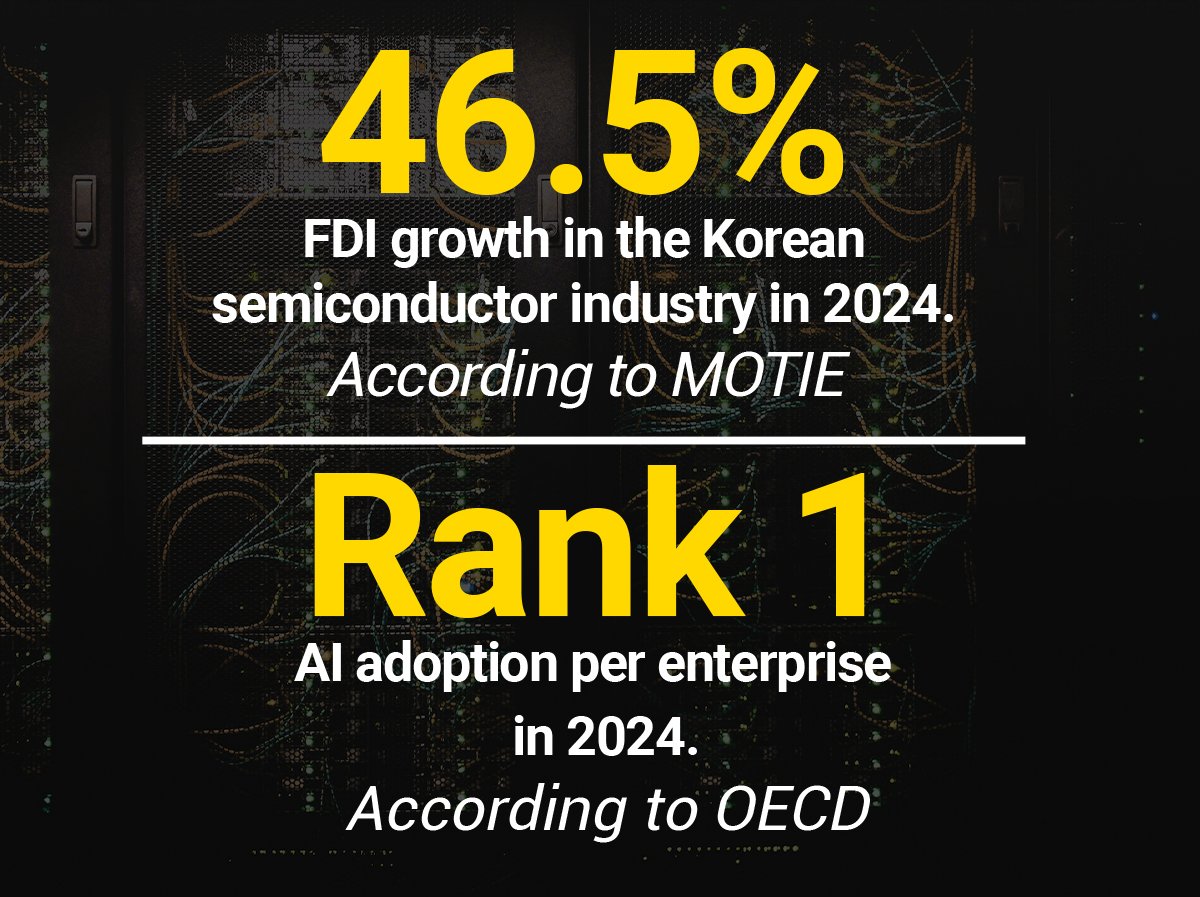

Source: MOTIE and OECD.

In semiconductor wafer production, chemical mechanical planarization (CMP) is crucial for ensuring precision, yield and quality. KC Tech develops both the machinery and the slurry in close partnership with its clients. “Our strategy is to build partnerships that allow us to jointly develop technologies tailored to the unique needs of each region,” says CEO Ho Keun Yang.

Successes such as these, although often overlooked, have been instrumental in advancing modern technology. These advancements aren’t created in a vacuum; South Korea’s substantial investment and education play a significant role in shaping the future of development and innovation. Sejong University‘s AI Convergence College combines AI, data science and IT with electrical engineering, robotics and mechatronics to create a hub for advanced industries. President Jonghwa Eom explains, “First and foremost, we aim to cultivate a strong foundation of essential skills among our students.” At its core, the college aims to provide technology-focused courses that emphasize problem-solving and teamwork, preparing budding innovators in South Korea for future technological challenges. The country is creating a virtuous circle to become the world leader in AI development and implementation.

Korean software firms are global contenders in the race for AI, with Younglimwon Soft Lab creating ERP solutions that leverage AI to transcend the one-size-fits-all solutions typically offered by international giants. “The enterprise software platforms of the 21st century must strongly integrate cloud computing, mobile accessibility and AI-driven automation to enhance efficiency and decision-making,” CEO Young-Bum Kwon says.

Factory floors across Korea are adopting AI to improve operations and throughput. Samkee, specialist in aluminum die-casting, was among the first to utilize it to automate part inspections, a previously manual and labor-intensive process. “With machine learning and AI vision technologies, we have reduced human error and significantly improved reliability and robustness,” CEO Chihwan Kim explains. AI inspections are becoming commonplace across industries, with top battery manufacturer Sebang Global Battery implementing them across its operations. In the modern market, fraught with geopolitical challenges like tariffs and regional instability, reliability and resilience are paramount. “The ability to maintain a flexible supply chain and respond to regional market conditions has become more critical than ever,” CEO Jung Hee Park explains. The company has built supply chain resilience by diversifying logistics and sales networks globally and integrating operations vertically.

Through strategic investments in innovation, government support and its thriving business ecosystem, South Korea continues to grow into a reliable partner for technology and manufacturing.

This report has been paid for by a third party. The views and opinions expressed are not those of Newsweek and are not an endorsement of the products, services or persons mentioned.