In the field of petroleum engineering, multistage fracturing in horizontal wells is a core technology for the economical and efficient development of unconventional oil and gas resources (such as shale gas, shale oil, tight gas, tight oil, etc.). Current mainstream horizontal well fracturing techniques and their geological applicability are categorized as follows:

(1) Plug-and-Perf Fracturing.

Principle: A bridge plug is run via wireline or coiled tubing to isolate previously fractured stages. The new stage is perforated with a gun and fractured. This process is repeated. Bridge plugs are categorized as drillable (removed by drilling later) or dissolvable (self-degrading).

Applicability: Long horizontal sections: Flexible stage count.Highly heterogeneous reservoirs: Allows arbitrary adjustment of perforation locations for targeted stimulation of sweet spots.Applicable to shale oil/gas development; serves as the backbone technique of the North American shale revolution.

Advantages: Precise staging, strong adaptability; dissolvable plugs eliminate milling, protecting the reservoir.

Limitations: Long operational cycle; wireline perforation requires multiple pump-down operations; plug drilling adds cost (except for dissolvable plugs).

(2) Sleeve Staged Fracturing.

Principle: Multiple fracturing valves with sleeves are pre-installed on the casing. Sleeves are sequentially opened by dropping balls (of different diameters) or via coiled tubing (CT), enabling stage-by-stage fracturing.

Applicability: Shale Gas/Shale Oil: Preferred for large-scale factory-mode operations; suitable for long horizontal sections. Tight Sandstone: Enables rapid and efficient staging; ideal for blocks with good reservoir homogeneity where precise location control is unnecessary.

Advantages: High operational speed, low cost; enables one-time completion of multistage fracturing.

Limitations: Gradual reduction in sleeve inner diameter restricts future production tubing; inability to precisely control fracture location.

(3) Coiled Tubing Hydrajet Perforating & Fracturing.

Principle: Utilizes a jetting tool conveyed by coiled tubing. High-velocity water jets perforate the formation and leverage the “jet-induced pressure boosting effect” (dynamic isolation) to initiate fracturing directly. Multistage operations are completed by pulling the tool up stage by stage.

Applicability: Open-hole or Cased Hole: Particularly suitable for uncased horizontal wells.Thin Interbeds/Complex Lithology: Allows precise targeting of fracture points, avoiding faults or water zones.Low-Pressure Reservoirs: Eliminates need for mechanical isolation, avoiding packer setting difficulties.

Advantages: No need for plugs or sleeves, enabling full-bore production; flexible operations.

Limitations: Longer operational cycles, higher cost; higher risk of screenout.

(4) Mechanical Packer Isolation Fracturing.

Principle: Multiple mechanical packers (e.g., inflatable or compression-set) are assembled in series on the fracturing string. Stages are isolated by the packers, allowing sequential fracturing.

Applicability: Medium-to-Short Horizontal Sections: Economically efficient when stage count is low. Carbonate Reservoirs: Commonly used in acid fracturing operations; packers exhibit strong acid resistance.

Advantages: Single-trip string run enables continuous operations; no ball seat restrictions, providing large bore access.

Limitations: High risk of stuck pipe; low efficiency for long horizontal sections; requires high wellbore quality.

(5) Diverted Fracturing with Temporary Plugging Agents.

Principle: Temporary plugging agents (e.g., balls, particulates) are pumped during a single fracturing treatment to seal existing fractures. This diverts fluid to new zones, achieving “infinite-stage” fracturing.

Applicability: Naturally Fractured Zones: Leverages natural fractures to create complex fracture networks. Re-fracturing of Old Wells: Activates unstimulated zones.

Advantages: No need for staging tools, reducing cost; suitable for complex fracture network stimulation.Limitations: Diversion effectiveness is difficult to predict; plugging agents may cause reservoir damage.

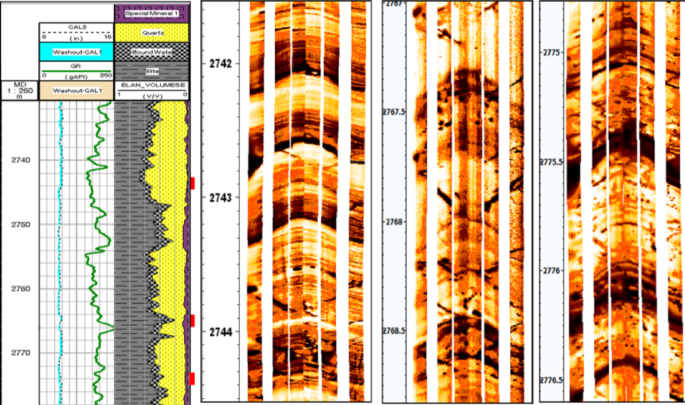

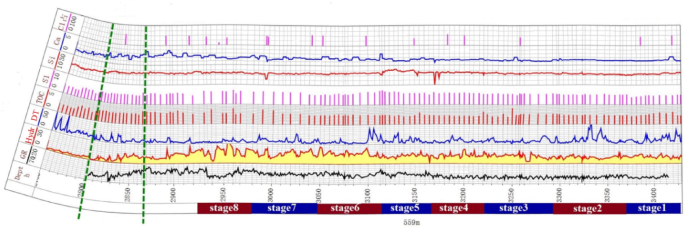

Horizontal well multi-stage fracturing technology has been extensively deployed in tight sandstone reservoirs across the Ordos Basin21,22,23. These field applications provide substantial operational benchmarks for designing fracturing parameters in Well DPX. Integrating historical fracturing experience from horizontal wells in the Ordos Basin while comprehensively evaluating Well DPX’s reservoir geological characteristics, development costs, and engineering risks, drillable plug-and-perf staged fracturing was selected for the multi-stage stimulation pilot. Subsequent fracturing treatment parameters were designed accordingly24,25,26. 8-stage fracturing is applied with two clusters in stage of the second, third, fourth, fifth and the eighth stages, shown in Fig. 17 and the detail parameters illustrated in Table 2. Here long cluster type is used with a perforation length of 1.5–3 m per cluster, larger aperture perforations are adopted to reduce perforation friction.

It is important to implement acid pretreatment according to the well completion and the mini fracturing test situation. In the initial stag, variable flow rate, variable viscosity, and pre ceramic proppant technology is taken to control the fracture height and ensure the propagation of main fraction, usually the flow rate is controlled between 8 m3/min and 12 m3/min27.

The new fracturing fluid adopts a combination of crosslinked fluid and slickwater. Compared with the traditional fracturing fluid containing only crosslinked fluid, it is more suitable for fracturing stimulation of the Chang-7 shale gas reservoir. The action process of the fracturing fluid is as follows: crosslinked fluid is pad fluid, slickwater is used to generate micro factrue, and the crosslinked fluid is used to carry sand at the last period of the process. The Fracturing treatment is implemented with liquid nitrogen to Improve the flowback effect. The injection of proppant is not continuous but intermittent. The optimum range of fracture fluid volume of each stage is between 800 m3 to 1000 m3. Due to high clay content, the fracturing fluid system should be adjusted to to inhibit the expansion of clay. Tables 3 and 4 represent the property of crosslinked fluid and slippery water。.

Considering the closure stress, proppant pressure resistance, crushing rate, conductivity and other factors, the proppant combination is as follows: 100 mesh ceramsite, 30/50 mesh ceramsite and 20/40 mesh ceramsite20,28.

Fracturing operation

In the total eight stages of fracturing, three of them are easily approached, whereas more difficult conditions with high pressure and sand plug are confronted in the other five.

(1)

Instance 1.

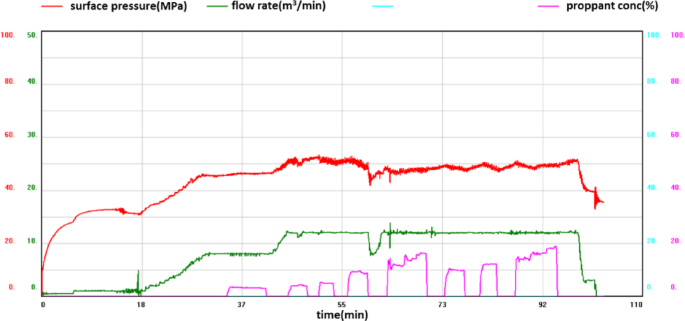

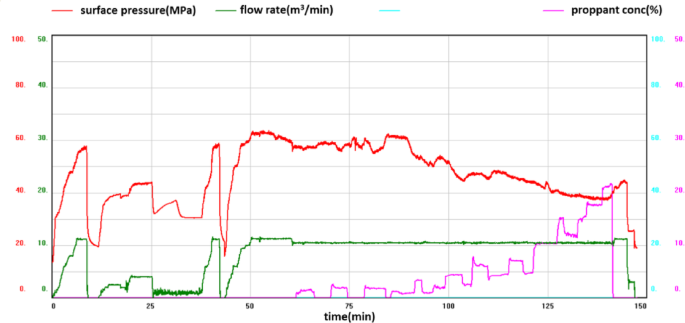

Stage 1 (Fig. 18): Injection process and slug sand-group pack technique are adopted. Slickwater and crosslinked fluid are used alternately. In particular, 440 m3 slickwater are injected, following with 374 m3 crosslinked fluid and 16 m3 acid, totally 40.1 m3 proppant are used.

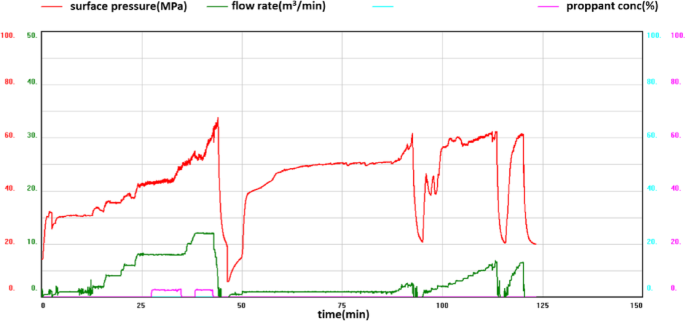

Stage 2 (Fig. 19): Injection process: plug type. Fluid injection type: slickwater and crosslinked fluid are used alternately with 430 m3 slickwater, 430 m3crosslinked fluid and 10 m3 acid, 53 m3 proppant.

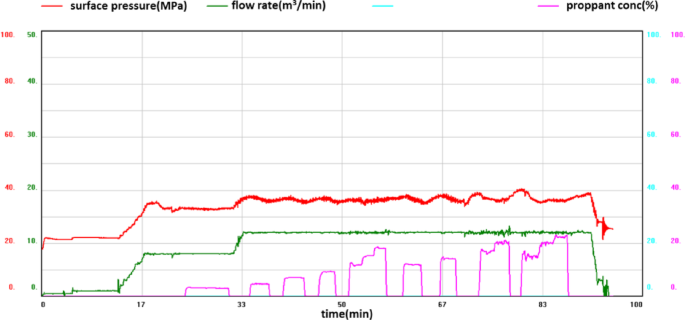

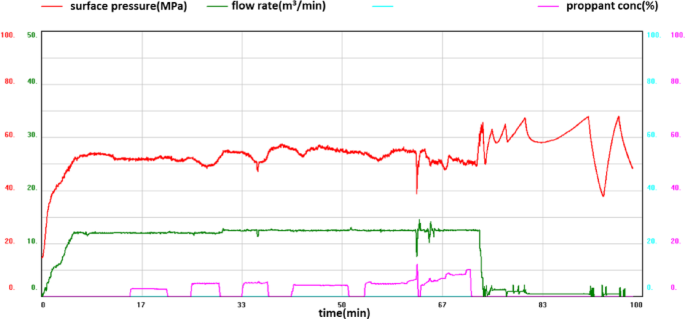

Stage 6 (Fig. 20): Due to the high treatment pressure, the injection process is different from stage1 and stage2.Injection process: multistep type with variable proppant concentration(The ratio of proppant and carrier fluid). Fluid injection type: slickwater and crosslinked fluid are used alternately with 493 m3 slickwater, 700 m3 crosslinked fluid and 13 m3 acid, 42 m3 proppant.

(2)

Instance 2.

Lots of difficult conditions with high pressure and sand plug are confronted in the stage 3, stage 4, stage 7 and stage 8. In the stage 3, when the 3% proppant concentration is injected into formation, the treatment pressure rise rapidly until exceed the limiting safe pressure (Figs. 21 and 22)0.23 m3 proppant is injected after blowing off, reperforating and well clean-up(with coiled tubing).