US-based Lightbridge Corporation has announced that its advanced fuel samples are now fully contained within an experiment assembly, ready for a critical phase of testing.

The assembly is slated for irradiation inside the Advanced Test Reactor (ATR) at Idaho National Laboratory (INL) later this year, a process considered an essential step toward eventual regulatory approval and commercial deployment of the new fuel technology.

The test focuses on Lightbridge Fuel, a proprietary design that utilizes an enriched uranium-zirconium metallic alloy. This is a departure from the ceramic uranium dioxide fuel used in most of the world’s current reactors.

The company posits that the metallic alloy’s material properties could lead to enhanced performance, particularly in terms of heat transfer, which allows the fuel to operate at lower temperatures.

Key factor in reactor safety

This characteristic is a key factor in reactor safety margins. The upcoming irradiation test is designed to gather empirical data on how the fuel behaves under simulated reactor conditions, providing the performance validation required by regulatory bodies like the US Nuclear Regulatory Commission before any new fuel can be licensed for use in commercial power plants.

“This achievement brings us closer to obtaining the rigorous irradiation testing data required for regulatory approval and eventual commercialization of Lightbridge Fuel,” said Dr. Scott Holcombe, Vice President of Engineering at Lightbridge.

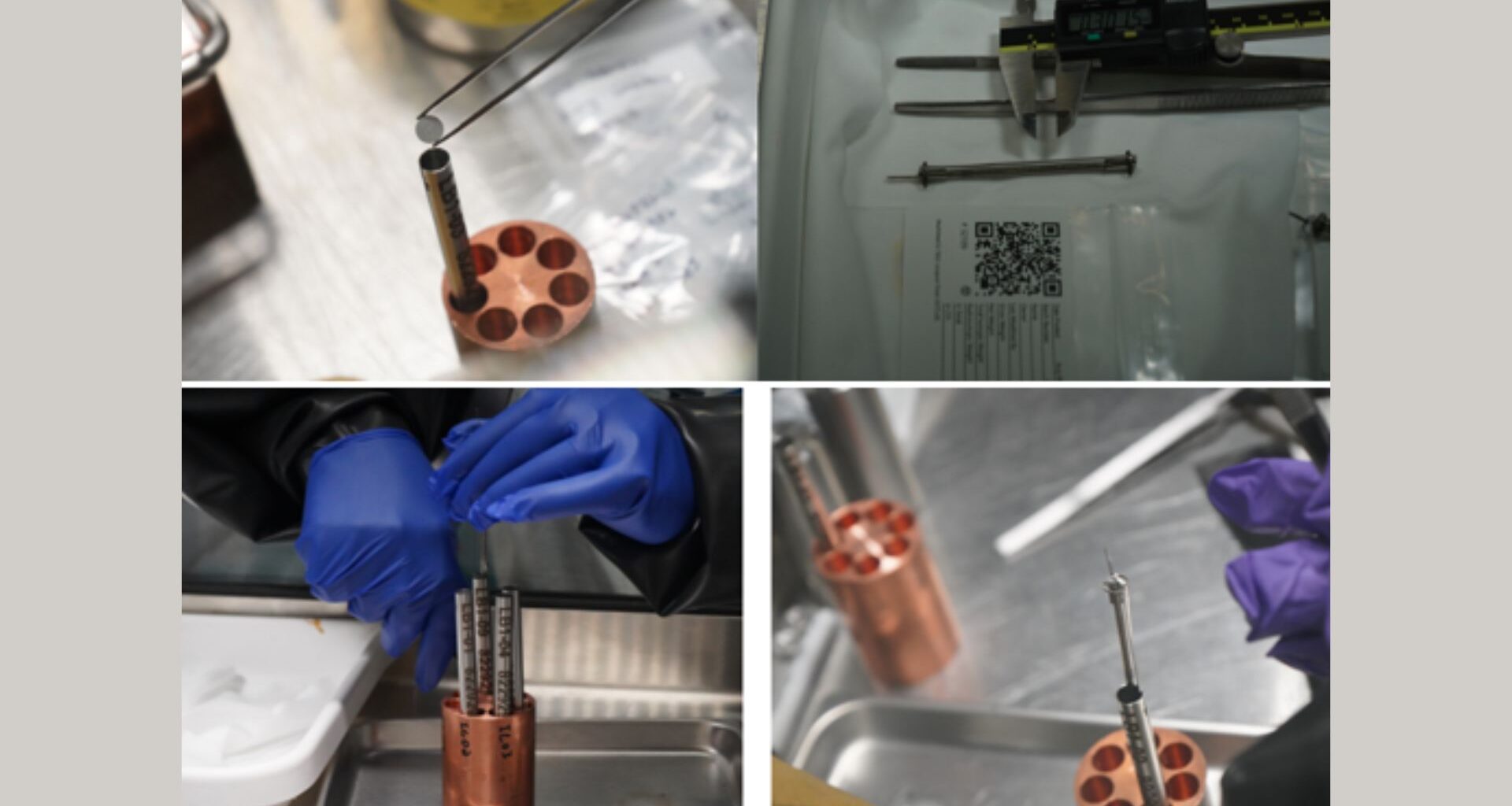

The intricate preparation work was conducted at INL, the United States’ leading center for nuclear energy research. The process involved manufacturing the alloy samples to precise specifications and then meticulously loading them into protective capsules. These capsules were then carefully arranged and sealed within the final experiment assembly.

Ready to be tested

This assembly is now ready to be placed inside the core of the Advanced Test Reactor, a unique facility designed specifically to subject materials to the intense neutron radiation and harsh physical conditions found inside a commercial nuclear power station, but in a highly controlled and instrumented setting.

This project exemplifies a public-private partnership, formalized under a Cooperative Research and Development Agreement (CRADA), which enables federal laboratories to collaborate with private industry to accelerate technological innovation.

“We are proud to collaborate with Lightbridge on the assembly of this irradiation experiment,” said Jess Gehin, Associate Laboratory Director for Nuclear Science & Technology at INL.

“This is an important step in testing and validating the performance of Lightbridge’s advanced fuel in a test reactor environment.”

Next phase for detailed analysis

Following the irradiation cycle in the ATR, the fuel samples will be moved to heavily shielded “hot cells” for post-irradiation examination.

This next phase will involve detailed analysis to assess changes in the fuel’s material structure and integrity, providing the essential data to determine its suitability for powering the existing fleet of reactors and a new generation of small modular reactors.

Earlier, the company has highlighted that the Lightbridge Fuel is not only designed for existing reactors. The company is also developing versions for next-generation small modular reactors (SMRs).