Newswise — Researchers from Universiti Kebangsaan Malaysia, et al. have conducted a review entitled “Advancement in membrane spacer technology: emerging trend and modification of three-dimensional printed membrane spacers for fouling mitigation”. This review was published in Front. Chem. Sci. Eng., Volume 19, Issue 11.

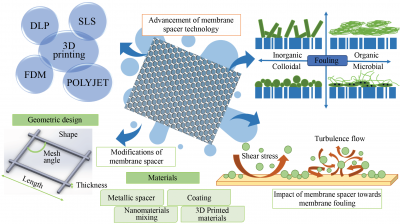

Membrane filtration is an effective water purification method, and membrane spacers are key components influencing system performance. However, fouling (especially biofouling) and related issues like feed channel pressure drop and stagnant zones severely reduce filtration efficiency. The aim of this review was to summarize advancements in membrane spacer technology. The researchers focused on modifications of spacer geometric design (e.g., shape, thickness, mesh angle), material innovation (e.g., traditional polypropylene, metallic materials, nanomaterial coatings), and 3D printing fabrication (including SLS, DLP, Polyjet, FDM methods). They also discussed 2D and 3D simulations for optimizing spacer performance. Key findings revealed that optimized geometric designs (e.g., multi-layer, honeycomb-shaped), novel materials (e.g., ZnO-coated, graphene-blended), and 3D-printed spacers significantly enhance antifouling ability, improve hydrodynamics, and reduce energy consumption.

For more detailed information, the full paper is available at: https://doi.org/10.1007/s11705-025-2606-6.