By redesigning LNG receiving terminals, the study demonstrates efficient recovery of ethane and liquefied petroleum gas (LPG) using only ambient-temperature seawater as the heat source. A techno-economic comparison of three process configurations indicates that regasification facilities can simultaneously deliver pipeline-quality natural gas and high-value petrochemical feedstocks, improving profitability, energy efficiency, and environmental performance.

Natural gas is the world’s fastest-growing fossil fuel and the cleanest in terms of combustion emissions. For long-distance transport, it is commonly shipped as LNG, a process that is energy-intensive but leaves behind substantial cold energy—around half of the energy consumed during liquefaction. Today, much of this cold potential is wasted at regasification terminals, where LNG is simply warmed using seawater or air. Over the past decades, researchers have proposed using LNG cold energy for power generation, air separation, desalination, and carbon capture. Among these options, recovering higher hydrocarbons stands out economically, especially in regions with strong petrochemical demand, because ethane and LPG command higher market value than natural gas burned as fuel.

A study (DOI:10.48130/een-0025-0013) published in Energy & Environment Nexus on 16 December 2025 by Shing-hon Wong’s team, The University of Western Australia, demonstrates that smarter use of LNG cold energy can unlock both economic and environmental benefits, offering a compelling pathway for more sustainable and profitable LNG infrastructure worldwide.

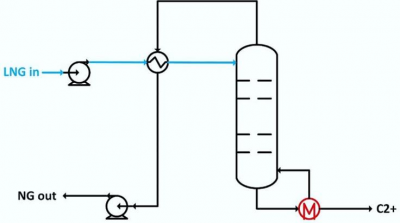

The study first adopted a systematic process‐simulation and optimisation approach to evaluate three alternative LNG hydrocarbon recovery configurations. Using Aspen HYSYS, the researchers optimised key operating parameters—primarily the pressures and temperatures of the demethanizer and deethanizer columns—while fixing all reboiler temperatures at 0 °C to enable effective heat transfer with ambient-temperature seawater. Designs 1 and 2 were optimised by simulating the two columns separately, as downstream operations did not influence demethanizer performance; the demethanizer pressure was varied to minimise ethane loss in the overhead stream, followed by deethanizer optimisation to achieve a 95 mol% ethane product specification. Design 3 required simultaneous simulation of both columns because LNG first cooled the deethanizer before entering the demethanizer, creating strong interdependence between units. In parallel, economic performance was assessed using the Aspen Process Economic Analyzer under consistent assumptions, and discrete sensitivity analyses were conducted to test robustness against changes in LNG flow rate, feed composition, and hydrocarbon prices. The optimisation results showed that Designs 1 and 2 performed similarly, with optimal demethanizer pressures around 1,670–1,690 kPa and deethanizer pressure at 380 kPa, recovering most ethane while keeping methane contamination within acceptable limits; Design 2 extracted slightly more ethane due to improved internal separation. Design 3 achieved the highest ethane recovery—about 5–6% more than the other designs—when operated at 1,600 kPa (demethanizer) and 380 kPa (deethanizer), but required significantly higher compression and reboiler duties. Economic analysis revealed that all designs were profitable under long-term average prices, with Design 2 being the most attractive due to its balance of recovery efficiency and lower operating costs. Sensitivity analysis confirmed that profitability scaled almost linearly with LNG throughput and depended strongly on feed composition, while extreme market conditions—such as ethane priced below natural gas—could temporarily negate economic gains.

The findings suggest that LNG receiving terminals can be transformed from passive infrastructure into value-adding hubs for petrochemical feedstock production. By using seawater, the proposed systems can be integrated into existing terminals with minimal additional energy input. Beyond economic gains, the designs avoid combustion-based heating, potentially lowering carbon dioxide emissions. Environmental impacts associated with cooled seawater discharge are comparable to current practices and can be managed with standard thermal controls.

###

References

DOI

Original Source URL

https://doi.org/10.48130/een-0025-0013

Funding information

The first author (Shing-Hon Wong) receives a PhD stipend scholarship from the Future Energy Exports CRC (www.fenex.org.au). This work has received partial support from the Australian Research Council under the Discovery Projects Scheme (Grant Nos DP210103766 and DP220100116).

About Energy & Environment Nexus

Energy & Environment Nexus is a multidisciplinary journal for communicating advances in the science, technology and engineering of energy, environment and their Nexus.