The chemical industry remains heavily reliant on fossil fuels to synthesize everyday products such as plastics, cosmetics, and medicines. To make these essential chemicals more sustainably, Erwin Reisner’s research group at the University of Cambridge has developed a “semi-artificial leaf” (Joule 2025, DOI: 10.1016/j.joule.2025.102165) that uses sunlight to produce hydrogen and formate—key compounds that can serve as building blocks for chemical manufacturing.

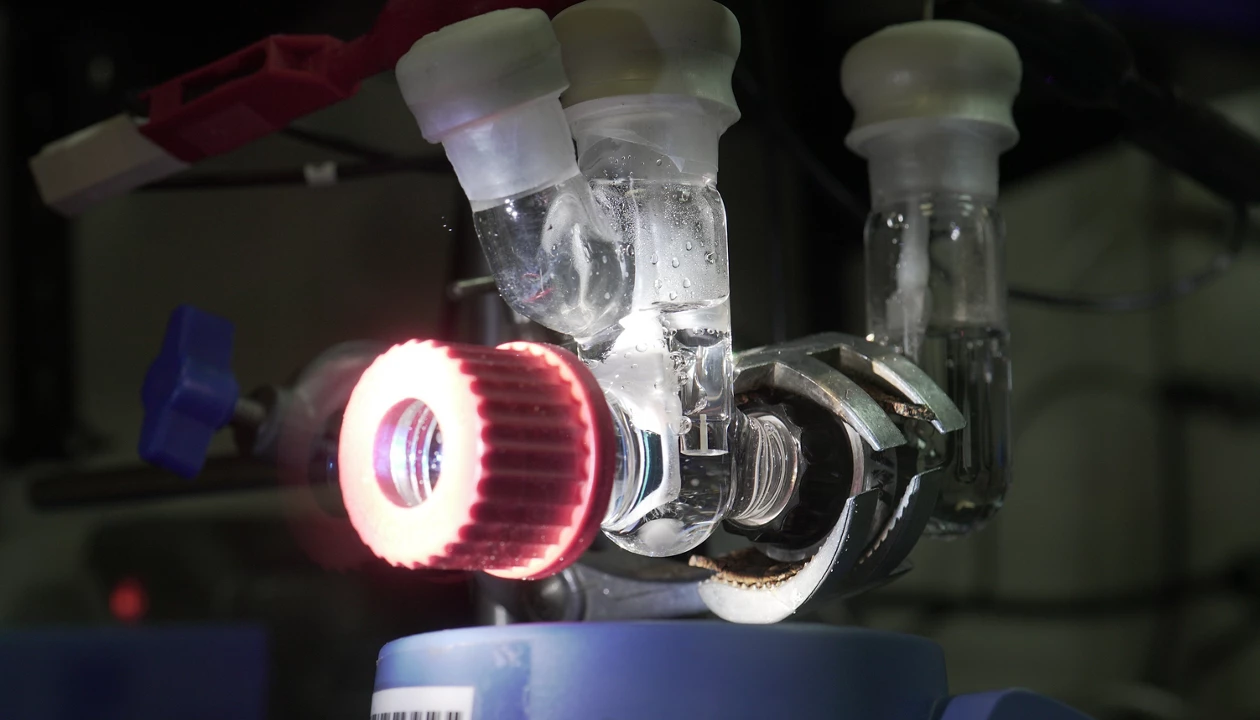

The device uses an organic semiconductor as a solar panel to generate electrons that are used to convert water and carbon dioxide to chemical fuels. The system uses natural enzymes as catalysts for the reaction and operates in a clean buffer system of sodium bicarbonate, mimicking the process of photosynthesis in a leaf.

“This marks an important step for the solar-fuel and artificial-photosynthesis community,” says Vivek Polshettiwar, a chemist at the Tata Institute of Fundamental Research, who was not involved in the study. “By directly coupling earth-abundant organic semiconductors with enzymes, without the need for sacrificial buffers, they’ve created a truly integrated biohybrid platform.”

While the group has explored artificial-leaf devices in the past, according to author Celine Yeung, this is the first time an organic solar cell has been interfaced with enzymes. With catalytically active sites finely tuned by evolution, enzymes facilitate reactions with higher selectivity and lower energy requirements than metal catalysts, which are often expensive and toxic. Together, these features create a cleaner, more sustainable alternative for solar-driven chemical production.

Reisner’s team also showed that the formate produced by the device can directly power a ruthenium-catalyzed asymmetric hydrogenation reaction, a common step in pharmaceutical synthesis. “This was a proof of concept,” Yeung says. Now the team plans to make some improvements. “We want to construct a full domino cascade reaction to synthesize more complex products.”

“This is basic science,” Reisner says. “We are delivering the roots to commercialization.” Yeung notes that a key limitation is that the enzymes are sensitive to oxygen, making it difficult to operate the device outside of laboratory conditions. “More importantly, we have to create more value in the process,” Reisner adds. Polshettiwar agrees that enzyme stability and long-term performance can pose challenges but thinks they can be overcome. He hopes the discovery will find its way into real-world technologies soon.

Chemical & Engineering News

ISSN 0009-2347

Copyright ©

2025 American Chemical Society