EPFL, a research university and engineering school in Lausanne, Switzerland, has researchers who developed a 3D printing method that grows metals and ceramics inside a water-based gel. This approach produces dense yet intricate structures suitable for energy, biomedical, and sensing applications.

Instead of using traditional metal powders, the method starts with a simple hydrogel and addresses limitations in vat photopolymerization, expanding its potential to create stronger and more complex parts.

Expanding the Capabilities of Vat Photopolymerization

Vat photopolymerization is a 3D printing process in which a light-sensitive resin is placed in a vat and selectively solidified by a laser or UV light. Despite its precision, the method has been mostly restricted to polymers that react to light, narrowing its potential for structural or functional parts.

While some methods have been developed to convert these polymers into metals or ceramics, Daryl Yee, head of the Laboratory for the Chemistry of Materials and Manufacturing at EPFL’s School of Engineering, notes that such efforts come with drawbacks. “These materials tend to be porous, which reduces their strength, and the parts suffer from excessive shrinkage, which causes warping,” he says.

A New Approach Using Hydrogels

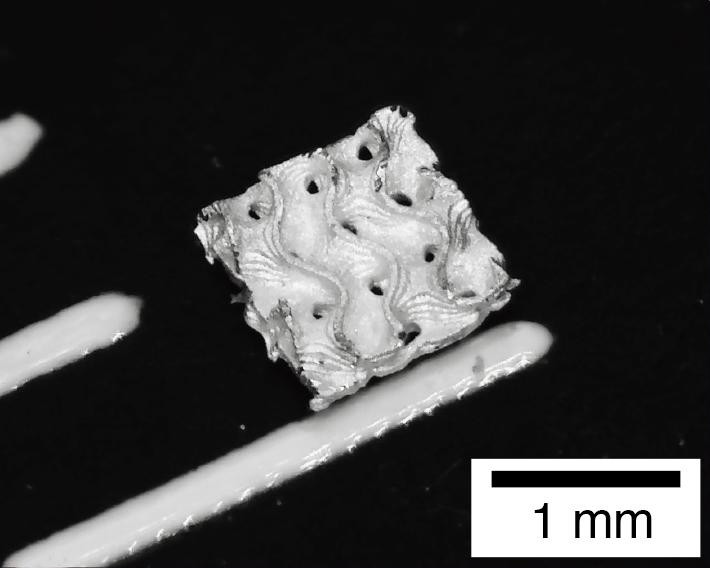

To overcome these issues, Yee and his team developed a new method that instead of directly curing a resin that already contains metal precursors, they first 3D print a simple water-based gel, or hydrogel. This blank structure is then infused with metal salts, which are chemically transformed into nanoparticles that spread throughout the scaffold. Repeating the process several times results in composites with exceptionally high metal content.

After five to ten growth cycles, the hydrogel is burned away in a final heating step, leaving behind a dense metal or ceramic structure that retains the shape of the original print. Because the metal infusion happens after printing, one hydrogel model can be converted into a variety of final materials.

“Our work not only enables the fabrication of high-quality metals and ceramics with an accessible, low-cost 3D printing process; it also highlights a new paradigm in additive manufacturing where material selection occurs after 3D printing, rather than before,” Yee summarizes.

Evaluating Strength and Complexity

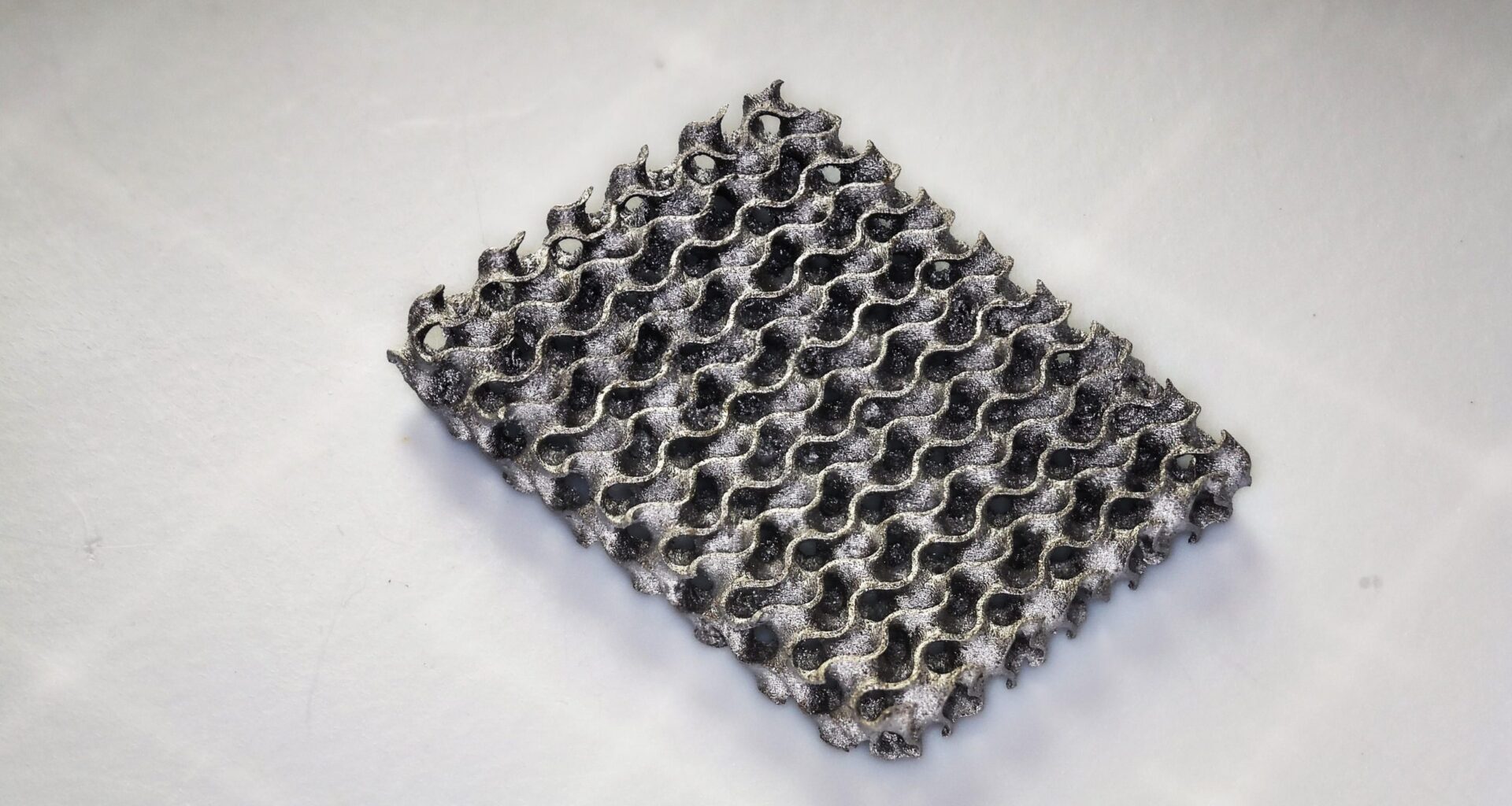

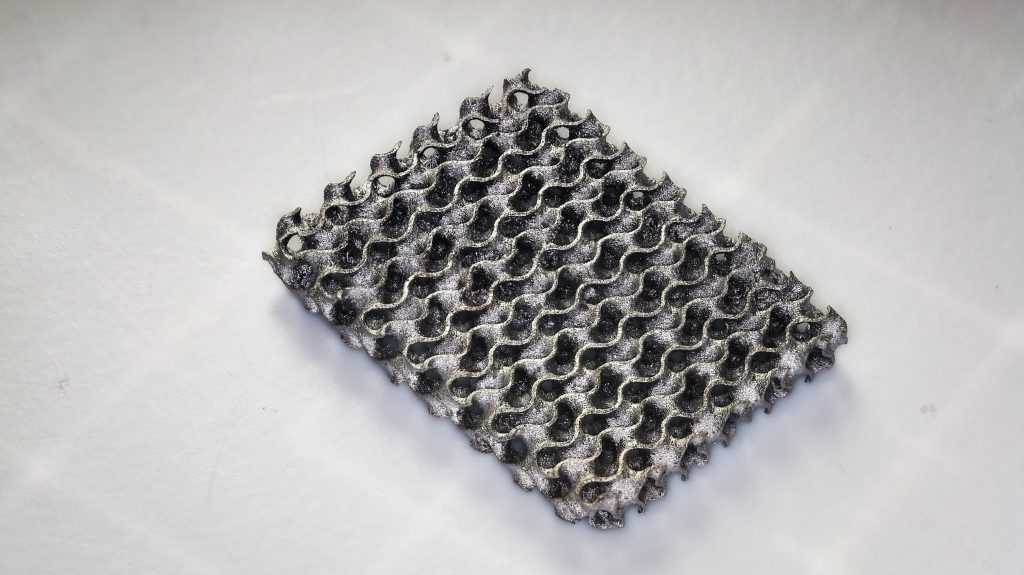

For their experiments, the team produced intricate lattice structures called gyroids from iron, silver, and copper to demonstrate that their method can create components that are both strong and geometrically complex. They tested the mechanical performance using a universal testing machine, which applies controlled pressure to measure strength.

“Our materials could withstand 20 times more pressure compared to those produced with previous methods, while showing only 20% shrinkage compared to 60–90%,” PhD student and first author Yiming Ji noted.

For future developments, the team is focusing on making the process more efficient for potential industrial use. Key objectives include improving material density and reducing production time, since the multiple infusion steps, while important for strength, make the method slower than other polymer-to-metal 3D printing techniques. “We are already working on bringing the total processing time down by using a robot to automate these steps,” Yee says.

Hydrogels in AM

Hydrogels have become an increasingly important medium in AM research due to their versatility as printable scaffolds. Earlier this year, researchers at EPFL and Uppsala University developed a novel technique that enables the fabrication of composite materials via volumetric additive manufacturing overcoming long-standing limitations in the field. Published in ACS Materials Letters, the study demonstrates how post-printing hydrogel infusion can convert transparent VAM-printed parts into functional composites with high filler content.

In another study, Caltech advanced metal 3D printing through hydrogel infusion additive manufacturing, showing how polymer templates can be transformed into functional metal structures. Hydrogels have also been explored in bioprinting and space applications, from xolography-based tissue engineering to improving radiation protection for astronauts.

Want to help shape the future of AM? Join the Expert Committee for our 2025 3DPI Awards, launching later this summer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our YouTube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows Large iron gyroid. Photo via EPFL.