A project led by Chinese researchers is exploring the conversion of construction waste into a valuable resource.

A new study led by Tsinghua University shows that recycled sand and gravel from demolished buildings could supply half of China’s construction material needs by 2050.

According to researchers, the use of advanced recycling technologies and circular economy practices could enable some provinces to recover up to 65 percent of aggregates.

The approach could drastically reduce raw material demand, easing pressure on natural resources as China continues to build roads, railways, and skyscrapers.

“Our study indicates that with targeted support, recycled aggregate production could meet a sizeable share of future demand at reasonable recycling rates,” said researchers in the study paper.

Recycling building boom

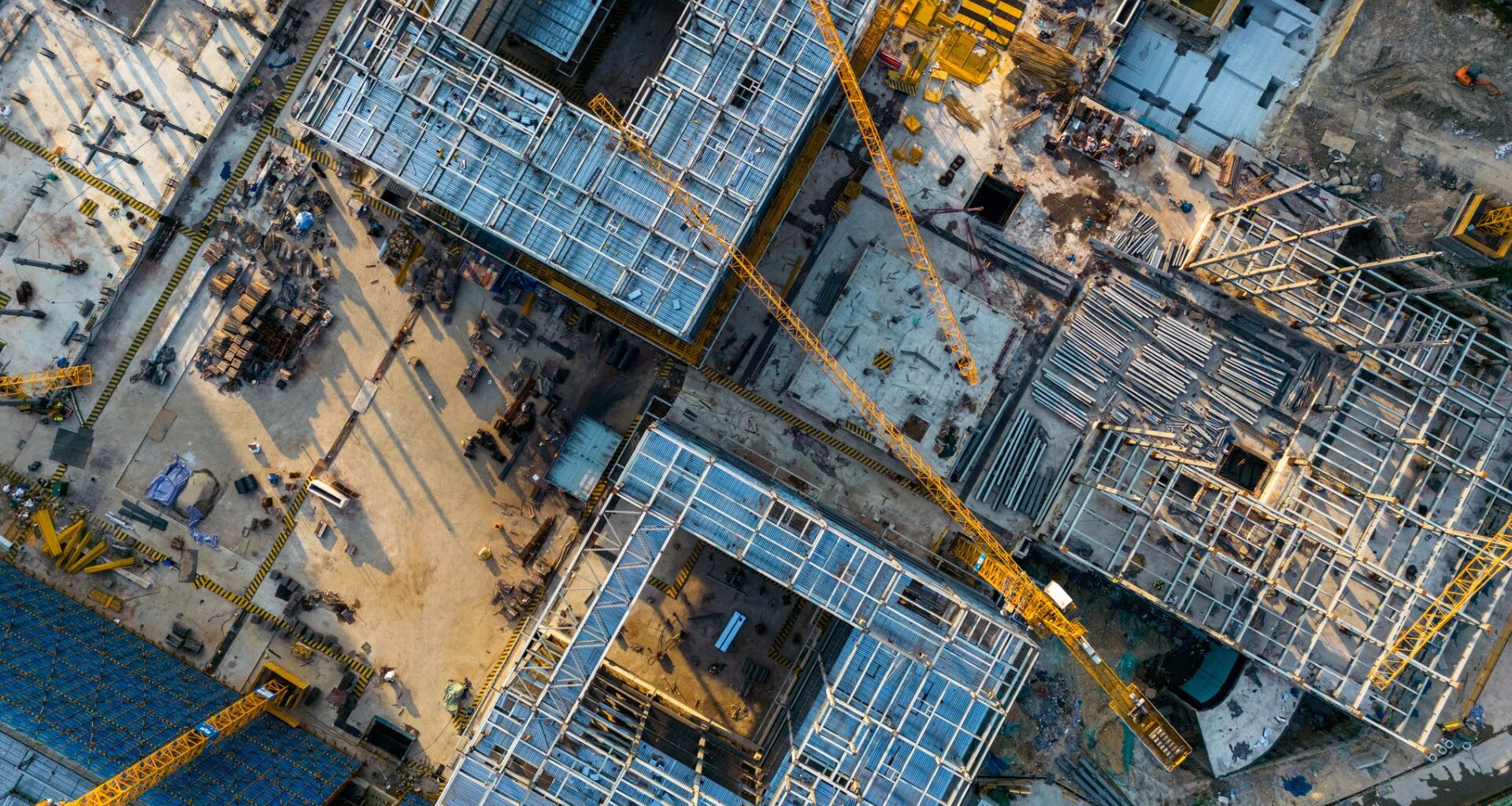

China’s decades-long construction boom has made it the world’s largest consumer of aggregates, accounting for nearly half of global usage. Massive urban projects—such as skyscrapers, railways, and highways—have driven an enormous demand for sand, gravel, and stone.

Historically, concrete production depended heavily on natural sand and gravel extracted from riverbeds, a practice that led to severe environmental degradation in some regions. Before 2005, approximately 80 percent of China’s aggregates came from these natural sources.

However, with growing awareness of ecological impacts, the industry has shifted toward crushed stone and artificial sand, which now account for approximately 80 percent of total aggregate use, according to the South China Morning Post.

This transition has reduced pressure on natural environments while supporting continued infrastructure expansion. Despite the scale of demand—peaking at 18.8 billion tonnes in 2015, equivalent to over 3,100 Great Pyramids of Giza—research into the long-term balance of China’s aggregate supply and demand remains limited.

Circular building blueprint

Researchers from Tsinghua University have now developed the China Aggregate Metabolism Provincial Scenarios (CHAMPS) model to map the supply and use of aggregates across 31 mainland provinces from 1978 to 2050.

The model applies circular economy principles—reduce, reuse, and recycle—to chart a more sustainable path for China’s sand and gravel industry. The strategy includes limiting per capita housing area, adopting lightweight designs, and extending building lifespans.

The team found that China’s aggregate demand peaked in 2015, with most provinces reaching their maximum before 2020. By 2050, annual demand is projected to decline to between 9.2 and 12.4 billion tonnes—a 50 percent reduction from its peak. According to SCMP, despite a shift toward manufactured aggregates, environmental concerns remain due to mountain quarrying. Recycling offers an alternative; however, current rates remain below 20 percent because most structures have not yet reached the end of their lifespan.

Under CHAMPS projections, recycling rates could rise to 35–65 percent by 2050, with recycled aggregates growing from 4 percent of the total supply in 2021 to 48 percent—surpassing manufactured aggregates around 2046. Their use in buildings could increase from 1 percent to 26 percent, and in infrastructure from 9 percent to 83 percent. The researchers emphasized that policy support is crucial for accelerating this transition and building a robust recycling system.

Globally, aggregate demand is expected to peak between 2060 and 2070, with China’s dominance waning as developing regions such as Africa, South Asia, and South America expand. The researchers said their framework could help these regions avoid China’s environmentally costly path and plan for more sustainable construction growth.

The details of the team’s research were published in the journal Nature Communications.