UCL – Understanding and optimising catalyst materials for sustainable hydrogen generation

Hydrogen is used in the production of chemicals such as ammonia and methanol, as well as the refinement of steels, and there is substantial growth predicted in the use of hydrogen in power, transportation, and synthetic fuel sectors.

However, most hydrogen currently produced is not carbon neutral – it is made from fossil fuels without capturing the resulting greenhouse gas. A solution to this is green hydrogen – made with no toxic emissions by using surplus renewable power to split water into hydrogen and oxygen. Currently this process requires scarce and precious materials catalysts such as platinum and iridium oxide, it is also exhibiting suboptimal levels of efficiency, thus making green hydrogen expensive and minimising adoption of this technology. There is also a lack of understanding of how and why the catalyst materials work on a fundamental level.

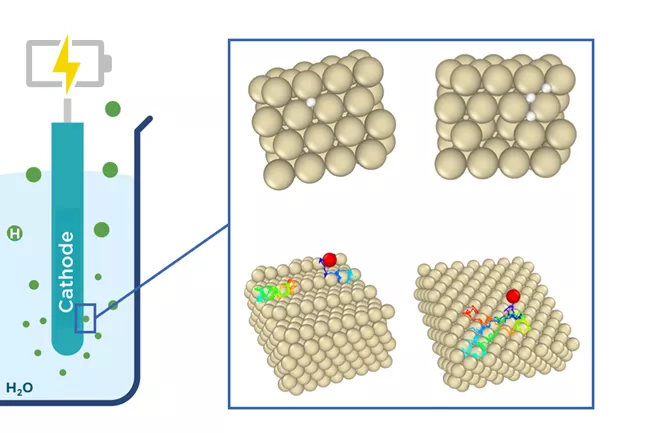

The aim of this research, in collaboration with bp, is to use computational experiments to explore the behaviour of hydrogen on the surface of catalyst materials. We use computational tools such as molecular dynamics and density functional theory to explore the catalyst materials on an atomic scale and identify the effects that catalyst surface alterations have on the behaviour of hydrogen. This will allow us to identify the factors that affect the material’s catalytic performance, and subsequently improve the catalyst materials for water electrolysis by increasing their intrinsic activity.

READ the latest news shaping the hydrogen market at Hydrogen Central

UCL – Understanding and optimising catalyst materials for sustainable hydrogen generation, source