Assembly with two containers and PVC piping delivery clean and renewable gas For daily use, focusing on stability, maintenance, and safety.

An updated DIY biogas system allows you to produce Free cooking gas all year round Using two blue plastic barrels and a simple PVC pipe layout, the system is designed for continuous operation, with a stable output and a feeding routine based on organic waste.

The proposal is noteworthy for combining straightforward assembly, readily available parts, and a process that can be implemented at home. The goal is to reduce reliance on gas cylinders, maintaining a renewable gas source with basic operational control.

— ARTICLE CONTINUES BELOW —

The result depends on three things: proper connection between the two barrels, well-organized piping, and frequent maintenance. Safety is a mandatory step, with leak tests and operation in a well-ventilated area.

The connection between two barrels stabilizes the gas output.

The solution uses two blue plastic barrels as the basis of the system, creating an interconnected volume that improves the regularity of supply. The assembly also uses PVC pipes and fittings, forming the gas transfer pathway to the point of use.

The key difference lies in the combination of simplicity with operational repetition. The system works with routine, proper feeding, checks, and adjustments, without relying on complex components to deliver a continuous flow.

The practical consequence is clear: local production reduces the need to buy gas cylinders and maintains the supply for everyday tasks. The focus is on autonomy with control and safety.

How to connect two kegs for a stable gas output.

The connection between the two barrels is the basis for a more consistent output. Instead of concentrating everything in a single container, the system distributes the volume and improves flow stability with… two interconnected barrels.

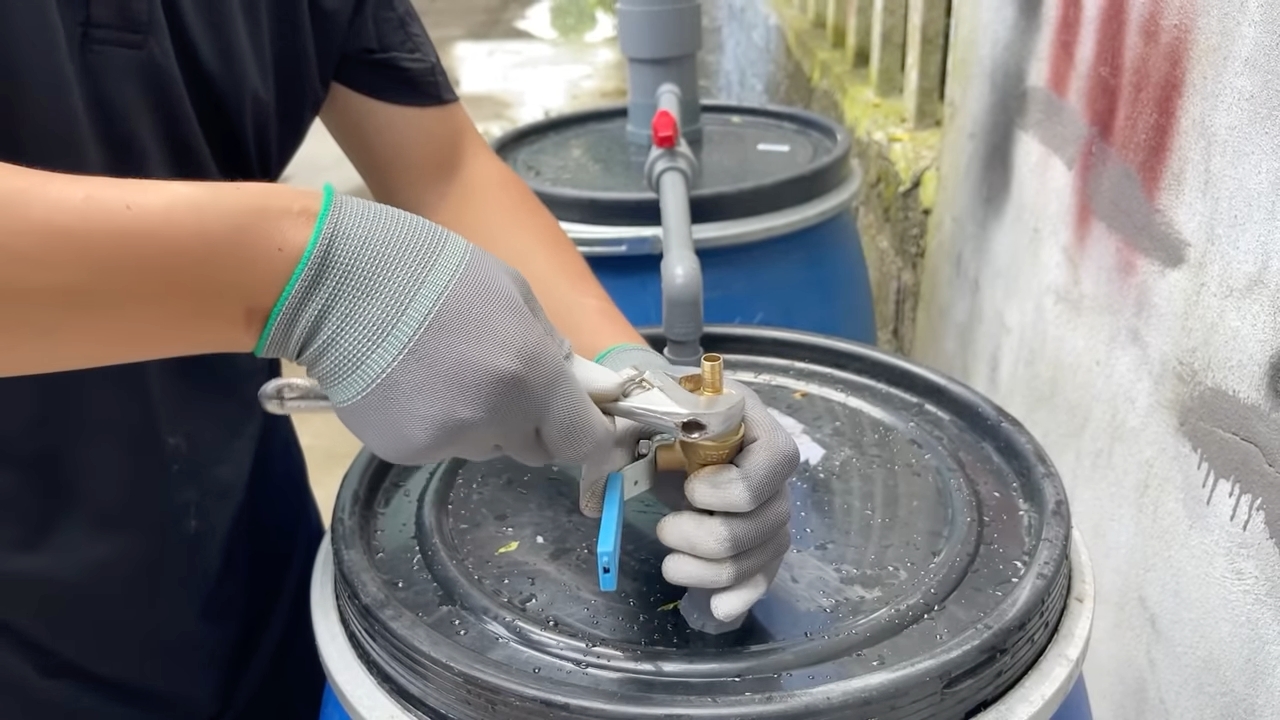

The assembly involves opening passage points and connecting the containers with PVC pipesUsing appropriate connections to keep the path secure, the fit needs to be tight, and the seal becomes critical to prevent leaks.

The impact becomes apparent in practice when the supply remains more consistent. This helps with daily use, especially in situations that require a constant flame and less variation in consumption.

Paying attention to the joints makes a difference. Proper sealing reduces leaks and improves the reliability of the assembly, keeping production more efficient.

PVC pipe layout for safe and efficient transfer.

The pipeline layout is simple, but it requires order and logic in its design. The path uses PVC pipes and fittings, including T-joint and elbow, to guide the flow and organize the line.

The transfer also provides for the use of non-return check valveThis helps prevent gas backflow and improves system safety. This type of component allows for more controlled operation.

The result is a more efficient flow path, with less risk of backflow and less need for intervention during operation. A well-designed line also facilitates visual inspection and spot corrections.

When necessary, the set may include a bubbler type water seal, which creates an intermediate step for control and reinforces safe operation.

Proper fermentation with organic waste maintains stable production.

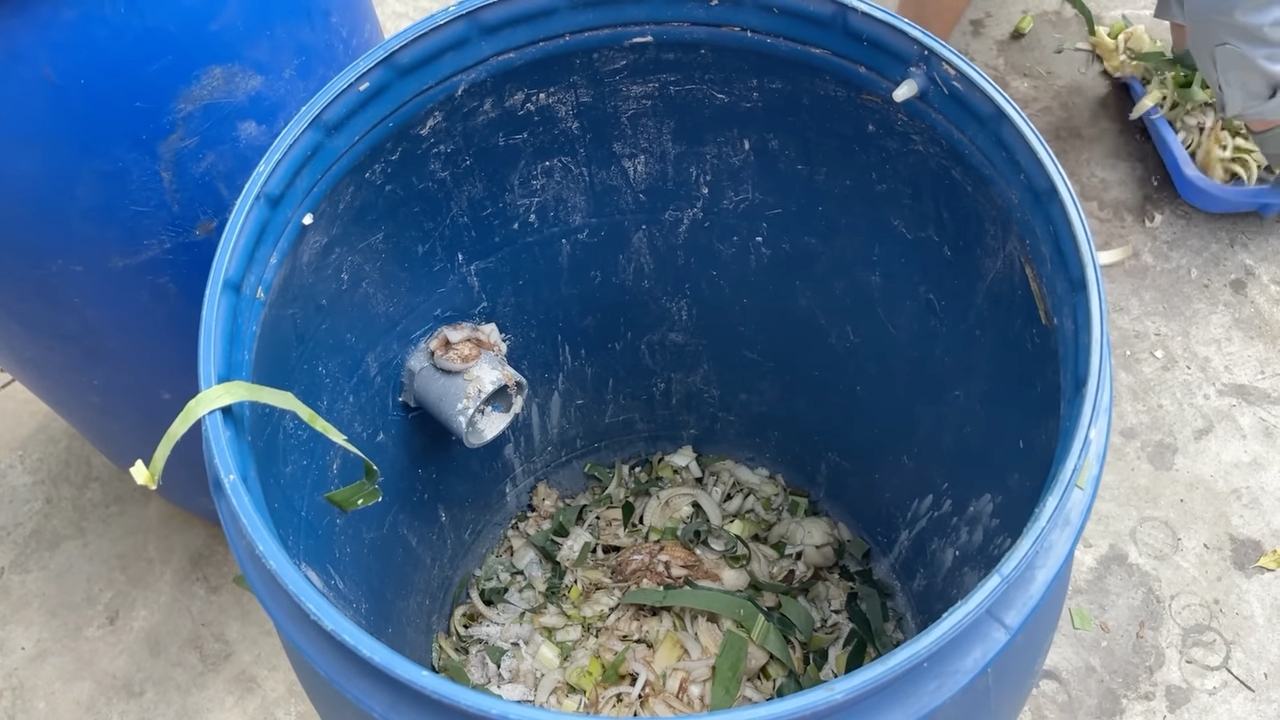

The stability of biogas depends on fermentation and careful feeding. The system uses raw material from organic waste, placed in the barrels to sustain the continuous generation of gas.

The operation requires routine and regularity. Feeding needs to avoid peaks, keeping the internal process more constant and reducing fluctuations in production. Proper sealing of containers also influences performance.

The result is a more stable generation over time, with better predictability for daily use. This consistency comes from controlling the intake and taking care with seals and caps.

One point to pay attention to is monitoring for signs of decreased production. Simple adjustments to the routine can prevent interruptions and keep the system reliable.

How to store, filter, and use gas for daily cooking.

After being produced, the gas needs to be transported to the point of consumption. The line can use gas hoseconnected to the circuit, providing flexibility to position the output according to need.

The set can also receive optional simple filter, installed in the line to reduce impurities and improve gas quality during use. Storage can be done in a volume connected to the circuit, allowing for reserves during periods of higher demand.

The practical change is the possibility of cooking daily without depending on gas cylinders. This reduces recurring costs and decreases the logistics of buying and exchanging them.

To maintain performance, it’s important to check connections and observe system behavior. Small, accumulated faults can reduce efficiency and compromise continuous use.

Tips for maintenance, odor control, and long-term reliability.

Long-term reliability depends on constant maintenance. The system requires repeated checks, cleaning, and correction of gaps in PVC pipes, covers and connection points.

The routine includes reapplying sealant when necessary, keeping the surrounding area clean, and monitoring the water seal’s operation when in use. This monitoring helps prevent instability and can contribute to reducing odors in the environment.

The direct result is less disruption and less need for emergency adjustments. Preventive maintenance is usually simpler than repairs after a failure.

It also helps to keep basic spare parts, such as fittings and short pipe sections, on hand for quick repairs without having to disassemble the entire line.

Points of attention and safety precautions when handling

The operation needs to take place in ventilated areasThis reduces the risk of gas buildup in enclosed spaces. It is also essential to avoid flames and sparks near the system, as biogas is combustible.

The leak test should be done with water and soap, applied to joints to identify bubbles and correct flaws. A non-return check valve It is a central part of preventing backflow.

The set should also use a siphonReinforcing physical barriers and increasing system control. These precautions enhance safety and protect performance, since leaks also mean gas loss.

Periodic testing is recommended, not just after assembly. Handling, vibration, and continuous use can loosen connections, requiring retightening and resealing.

The DIY biogas system with two blue barrels e PVC pipes This shows that continuous production depends on a stable connection, well-designed piping, and a fermentation routine with organic residues. Sealing, backflow prevention, and intermediate steps strengthen flow control.

The impact on domestic use is direct: less dependence on gas cylinders and greater autonomy with renewable gas for cooking. The result is sustainable when maintenance and safety are incorporated into the process, with frequent checks and operation in a well-ventilated environment.

Have you ever built a similar system or are you interested in trying it at home? Leave a comment and share!