Scientists of the University of Michigan at Ann Arbor have achieved a notable milestone in nitride semiconductor research by realising an exceptionally high two-dimensional electron gas density at room temperature in an aluminium nitride/gallium nitride heterostructure. Grown using plasma-assisted molecular beam epitaxy, the structure employs a single-channel design with a 9 nm AlN barrier, enabling electron concentrations above 1 × 10¹⁴ cm⁻² – an outcome that places this material system at the forefront of reported performance levels.

{alcircleadd}

To know the aluminium market outlook for 2026 and beyond, get an access to our report: Global Aluminium Industry Outlook 2026

Reported in Applied Physics Letters (Vol. 127, p. 243505, 2025), the work identifies how precise strain management and interface control can perfectly unlock performance levels, which were earlier considered difficult to sustain in AIN- driven heterostructures. The researchers suggest that the results could accelerate the development of aggressively scaled, thermally stable devices for millimetre-wave power amplification, RF front-end architectures, and other wide-bandgap electronics. For practical deployment, they note that integrating gate dielectrics such as Al₂O₃ or HfO₂, combined with refined interface engineering, would widen the reliability window for AlN/GaN high-electron-mobility transistors (HEMTs).

Rethinking barrier materials for high-density channels

Conventional lateral HEMTs typically rely on an undoped GaN channel capped with an aluminium gallium nitride (AlGaN) barrier to induce a 2DEG. While alternative barriers based on InAlN or ScAlN alloys can enhance carrier mobility, they generally suffer from substantially reduced electron densities. AlN, by contrast, offers the largest spontaneous and piezoelectric polarisation mismatch among III-nitride materials when paired with GaN, enabling exceptionally strong carrier confinement, provided strain is carefully controlled.

In AlN/GaN systems, the combined effects of lattice strain and polarisation discontinuities generate a deep potential well at the interface, where electrons accumulate without the need for intentional doping.

Read More: Alumina’s journey through 2025: A year known for ambition, friction and recalibration

Growth strategy and structural design

The heterostructures were grown on high-resistivity GaN-on-sapphire templates, with an additional 100 nm GaN layer regrown before depositing the AlN barrier. To suppress parasitic conduction, the GaN template incorporated vanadium doping. Barrier thickness was systematically varied, and the entire structure was capped with GaN to shield the AlN layer from atmospheric degradation, particularly oxidation, a known vulnerability of aluminium-rich compounds.

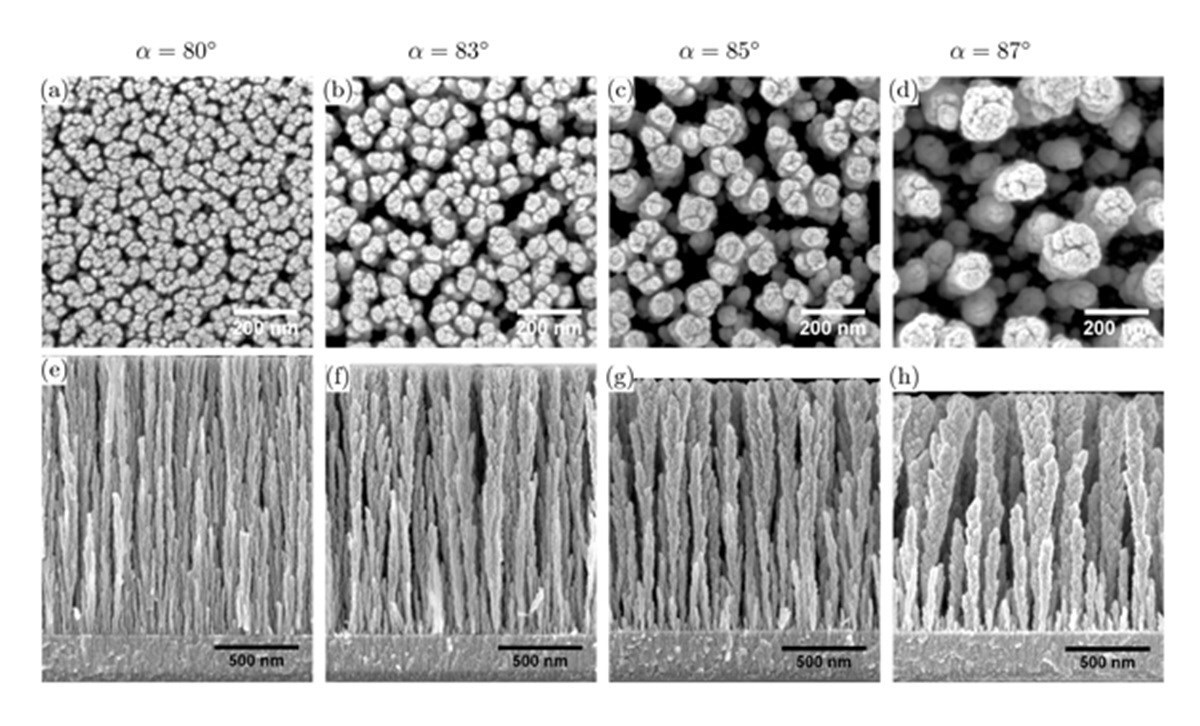

Growth was carried out at 600°C under metal-rich PAMBE conditions. According to the team, maintaining excess metal during deposition enhances surface adatom mobility, promoting lateral growth and yielding smoother, more uniform films.

Electrical performance trends

Van der Pauw Hall-effect measurements were used to extract carrier density, mobility, and sheet resistance at room temperature. As AlN thickness increased from 3 nm, electron mobility showed a consistent decline, falling from an initial value of 925.2 cm²/V·s. In contrast, carrier density rose sharply with barrier thickness, peaking at 1.3 × 10¹⁴ cm⁻² for the 9 nm sample.

The researchers attribute this record density to a combination of atomically abrupt interfaces and finely tuned strain control during epitaxy. However, when both mobility and density are considered together, the lowest sheet resistance, 166 ohm per square, was observed in the 6 nm barrier sample. This value places the structure among the best-performing AlN/GaN heterostructures reported to date. The 6 nm device exhibited a 2DEG density of 7.8 × 10¹³ cm⁻².

Strain relaxation and Its consequences

Closer inspection of the sample with a 9 nm AlN barrier showed the emergence of fine cracks, a clear sign that the layer had started to release accumulated strain. While the structure still supported a very high electron density, these structural imperfections translated into higher sheet resistance. The researchers note that, although theoretical calculations place the onset of strain relaxation for AlN on GaN at roughly 6.5 nm, real-world growth conditions mean that relaxation can begin earlier due to factors such as surface unevenness and the formation of defects.

A careful optimisation of the growth conditions helped researchers to preserve structural integrity even beyond this critical threshold, enabling the formation of ultra-high-density 2DEGs. They suggest that further mitigation of cracking, through approaches such as selective-area epitaxy or advanced strain engineering, could allow full exploitation of these densities in next-generation architectures, including Fin-HEMTs and multi-channel devices.

Mobility degradation mechanisms

The observed reduction in mobility with increasing barrier thickness was analysed in terms of three dominant scattering mechanisms: Coulomb interactions between carriers, collisions with polar optical phonons, and interface roughness scattering. Atomic force microscopy over 2 µm × 2 µm areas revealed surface roughness values of 0.21 nm for the 6 nm barrier and 0.28 nm for the 9 nm barrier, suggesting increased interface disorder at higher thicknesses.

A noticeable downward inflexion in mobility between the 6 nm and 7.5 nm samples points to the onset of enhanced interface-related scattering.

Temperature stability and cryogenic suitability

Low-temperature Hall measurements were also conducted, focusing on the 6 nm barrier structure. At 300 K, the sheet resistance measured 175 ohms/square and remained largely stable down to approximately 100 K, below which temperature-dependent scattering mechanisms became more pronounced. Importantly, the persistence of finite carrier density at cryogenic temperatures confirmed the absence of carrier freeze-out.

This behaviour demonstrates that the 2DEG is polarisation-induced rather than donor-driven, with negligible contributions from buffer leakage or unintentional silicon incorporation. The researchers observed a modest increase in carrier density at elevated temperatures, which they attribute to lattice contraction and corresponding changes in piezoelectric polarisation and band alignment.

Benchmarking against prior work

When compared with previously reported AlN/GaN heterostructures, the results establish new performance benchmarks, particularly in the relationship between barrier thickness, 2DEG density, and sheet resistance. The findings underscore the viability of AlN barriers for pushing electron densities to new limits without sacrificing operational robustness.

Taken together, the study demonstrates that carefully engineered AlN/GaN interfaces can deliver both extreme carrier densities and stable transport properties, reinforcing their potential for high-frequency, high-power, and even cryogenic electronic applications.

Explore- Most accurate data to drive business decisions with 50+ reports across the value chain