If only clean plastic can be recycled, why are Korean scientists asking us to keep the grime? The answer could flip the script on what belongs in the bin.

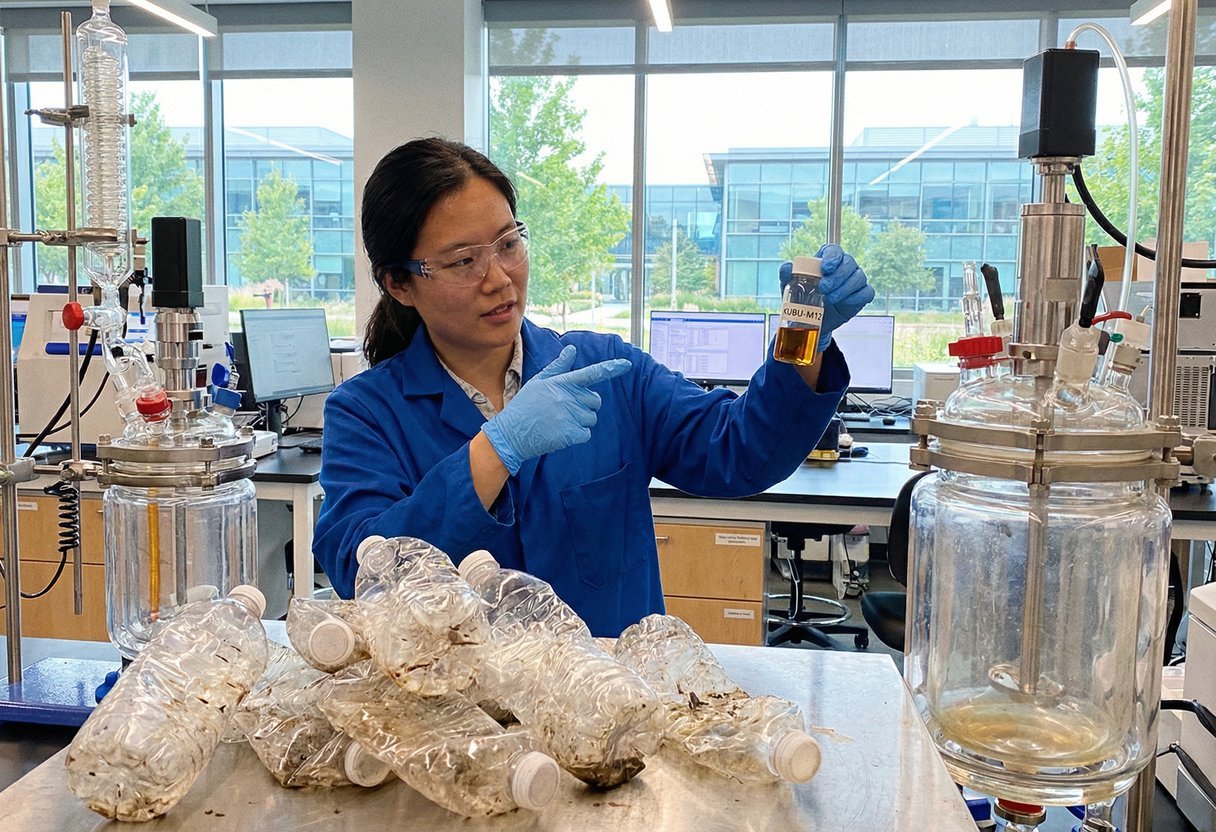

In a lab at Kyungpook National University, a soda bottle with dried ketchup on the rim no longer counts as trash. Under Professor Kim Kyung-jin, a custom biocatalyst dubbed KUBU-M12 pries PET back into its basic ingredients, sidestepping the washing and sorting that bog down most recycling lines. The payoff is not just lab spectacle: material once bound for landfills or the sea can feed a circular supply chain instead. And the stakes are high, with UNEP still counting only a sliver of global plastics as truly recycled.

Plastic pollution: a growing challenge

Plastic pollution has firmly established itself as one of the world’s most pressing environmental challenges. Globally, only about 10% of plastics are recycled; the rest either go to landfills, spill into oceans, or are incinerated, releasing harmful emissions. Among the culprits, polyethylene terephthalate (PET), widely used in bottles and packaging, is notorious and can take centuries to break down in nature.

Yet PET remains indispensable in everyday life because of its durability and versatility. Those same qualities make end-of-life management extremely difficult. A new solution from South Korea could change how plastic waste is treated.

PET plastics and their environmental toll

PET plastics, found in everything from water bottles to clothing fibers, are everywhere. Their production relies on petroleum and carries a heavy environmental footprint. Improper disposal fragments PET into microplastics, tiny particles that infiltrate ecosystems and harm marine and terrestrial life.

The scale is daunting: each year, millions of tons of plastic waste enter the environment. Conventional recycling struggles because PET must be carefully cleaned and often processed with intensive chemicals to be reused effectively, which limits adoption. A way to bypass these hurdles is now within reach.

Meet KUBU-M12: a biocatalyst breakthrough

Researchers in South Korea at Kyungpook National University, led by Professor Kim Kyung-jin, have developed a potent new tool against plastic waste: the KUBU-M12 biocatalyst. Inspired by natural enzymes, it depolymerizes PET into basic building blocks ready for reuse, and it can work in under 48 hours.

KUBU-M12 is notably practical. Unlike many conventional methods, it processes plastics even when contaminated, such as unwashed soda bottles or food packaging. By removing a major bottleneck in recycling, this advance could streamline PET waste management worldwide.

Why KUBU-M12 could change everything

Beyond speed and efficiency, the KUBU-M12 biocatalyst delivers clear advantages:

- Decomposes up to 90% of PET plastics within 48 hours.

- Reduces the need for intensive pre-cleaning processes.

- Potentially allows PET plastics to be recycled multiple times without losing quality.

Such progress can make recycling more cost effective and accelerate a more circular economy. With less new plastic required, reliance on fossil fuels falls and carbon emissions can be reduced.

Reversing the tide of plastic waste

The environmental upside is significant. Landfills and oceans could experience a sharp drop in plastic contamination. Lower demand for crude oil in plastic manufacturing would ease pressure on natural resources, allowing ecosystems to recover.

Real change will take more than breakthrough technology like KUBU-M12; it also depends on public awareness, responsible consumption, and sustained action by individuals, companies, and governments. Start by reducing waste today: reuse that bottle or ensure it is correctly recycled.

The world may not solve plastic pollution overnight, but innovations like this renew hope. The future of recycling leaves inefficiency behind and embraces smarter, greener alternatives.

Source : https://www.science.org/doi/10.1126/science.adp5637