Donald Trump can be described as many things. Some would call him a patriot — his ‘Make America Great Again’ stance is evidence of it, while others may call him a flip-flopper — he made a dramatic U-turn on tariffs earlier this week, barring China.

But it’s not often that Trump is referred to as a dreamer, at least until now. As he wages a trade war with China — the US president has levied a whopping 145 per cent tariff on the Asian giant — he hopes for the tech giant, Apple, to produce its flagship product, the iPhone, in the United States.

But Apple executives as well as other analysts believe this is nothing beyond wishful thinking. Additionally, analysts note that even if the impossible is achieved, it would be a very, very expensive affair.

Here’s why.

Trump wants ‘made-in-US’ iPhones

Amidst the

raging tariff war with China, US President Donald Trump believes that America is capable of manufacturing iPhones.

On Tuesday (April 8), the White House Press Secretary Karoline Leavitt said, “Absolutely. He believes we have the labour, we have the workforce, we have the resources to do it,” when asked by reporters if Trump thought iPhone manufacturing could move to the US.

Reporter: “iPhones specifically. Is that something that he thinks is the kind of technology that can move to the US?”

Karoline Leavitt: “Absolutely. He believes we have the labor, we have the workforce, we have the resources to do it.” pic.twitter.com/Ruhu4cZpok

— The Post Millennial (@TPostMillennial) April 8, 2025

“If Apple didn’t think the US could do it, they probably wouldn’t have put up that big chunk of change,” she said, referring to the $500 billion investment the tech giant announced recently.

Trump doubled down on the claim on Wednesday, posting to his Truth Social network that: “This is a great time to move your company into the US, like Apple, and so many others, in record numbers, are doing.

“Zero tariffs, and almost immediate electrical/energy hook ups and approvals. No environmental delays.”

Customers enter the Apple Fifth Avenue store in Manhattan, New York City. Apple’s main manufacturing hub is China, with around 90 per cent of iPhones being assembled there. File image/Reuters

It’s important to note here that Apple’s main manufacturing hub is China, followed up by Vietnam and

India. According to estimates from Evercore ISI, around 90 per cent of iPhones are assembled in China.

Earlier, US Secretary of Commerce Howard Lutnick also pitched a proposal for US-made iPhones while in an interview with CBS. “The army of millions and millions of people screwing in little, little screws to make iPhones, that kind of thing is going to come to America, it’s going to be automated, and the tradecraft of America is going to fix them, is going to work on them, there’s going to be mechanics, HVAC specialists, electricians,” he said.

Lutnick: “The army of millions and millions of human beings screwing in little screws to make iPhones — that kind of thing is going to come to America.” pic.twitter.com/g9TqxGxLHs

— Aaron Rupar (@atrupar) April 6, 2025

Apple speaks on US-made iPhones

But it seems that Trump’s wish for an American-manufactured iPhone isn’t something that Apple envisions could happen. At least, not in the next few years.

In fact, iPhone maker’s founder Steve Jobs as far back as 2010 said that such a situation wasn’t possible. Walter Isaacson’s biography, Steve Jobs, clearly describes meetings between Jobs and then-President Barack Obama in 2010 and 2011, where Jobs explained that the problem is that America lacks the 30,000 properly trained engineers needed to support a factory workforce rivaling the 700,000 workers employed in China: Apple had 700,000 factory workers employed in China, he said, and that was because it needed 30,000 engineers on-site to support those workers.

“You can’t find that many in America to hire,” he said.

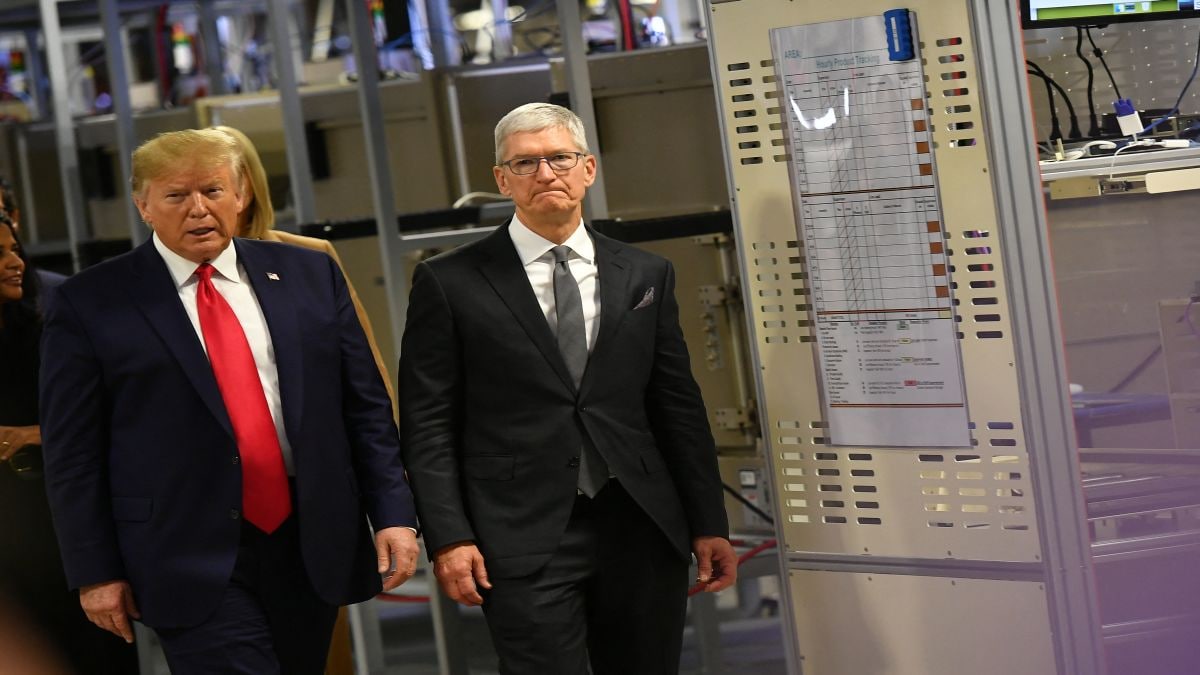

Even current CEO Tim Cook has rejected this notion. In 2017, at Fortune Magazine’s Global Forum event, Cook said companies like his relied on countries such as China not for cheap labour, but for the quality of trained employees.

“…The truth is China stopped being the low labour cost country many years ago and that is not the reason to come to China from a supply point of view. The reason is because of the skill and the quantity of skill in one location, and the type of skill. It is like the products we do require really advanced tooling and the precision that you have to have in tooling and working with the materials that we do are state-of-the-art, and the tooling skill is very deep here. You know in, in the US, you could have a meeting of tooling engineers, and I’m not sure we could fill the room — in China you could fill multiple football fields.”

Tim Cook: Why Apple still uses Chinese manufacturers pic.twitter.com/zd59LweSNS

— FORTUNE (@FortuneMagazine) December 7, 2017

America isn’t Apple land

Other experts have also chimed in on this issue. They believe that the US, unlike what Trump believes, doesn’t have the necessary requirements for Apple manufacturing.

For instance, Apple’s final assembly, test and pack-out (FATP) facilities in Asia are almost towns with several hundred thousand people, schools, gyms, medical facilities and dormitories. One major iPhone factory, a complex in Zhengzhou, has even been dubbed iPhone City.

Worker prepares new Apple iPhones in Shenyang in China’s northeastern Liaoning province. Analysts believe that America can’t provide Apple with the manufacturing and labour required to assemble iPhones. File image/AFP

“What city in America is going to put everything down and build only iPhones? Because there are millions of people employed by the Apple supply chain in China,” Matthew Moore, the co-founder of a startup and a former Apple manufacturing engineer, told Bloomberg. “Boston is over 500,000 people. The whole city would need to stop everything and start assembling iPhones.”

Tinglong Dai, a business professor at Johns Hopkins University, concurred with this sentiment. In a Wall Street Journal report, he is quoted as saying, “It wouldn’t be impossible to buy the manufacturing equipment required, but getting enough people who are able to run it might be. We have a severe labour shortage, and we’ve lost the art of manufacturing at scale.”

Also, if these two issues were miraculously solved, what about the issue of finance? Experts note that it would take millions of dollars for Apple to build the manufacturing ecosystem for an All-American iPhone.

Heavy cost of US-made iPhone

But even if Apple did pull off the impossible and moved manufacturing to the US, it would come at a very high price.

Dan Ives, global head of technology research at financial services firm Wedbush Securities, told CNN that the price of an Apple iPhone could soar to around $3,500 (Rs 3.01 lakh) if it were made in the US.

Apple CEO Tim Cook poses for a selfie with a visitor at the Apple Store on Broadway in downtown Los Angeles, California. If Apple were to assemble its phones here, the cost would triple, according to one tech analyst. File image/AFP

Speaking to CNN, he said that US-made iPhones could cost more than three times their current price of around $1,000 (Rs 86,081), because it would be necessary to replicate the highly complex production ecosystem that currently exists in Asia. “You build that (supply chain) in the US with a fab in West Virginia and New Jersey. They’ll be $3,500 iPhones,” he said.

In a separate interview with CBS, Ives said, “Saying we can just make this in the USA is a statement that incredibly understates the complexity of the Asia supply chain and the way electronics, chips, semi fabs, hardware, smartphones, etc, are made for US consumers over the last 30 years.”

Meanwhile, an April 3 analysis from Rosenblatt Securities warned that tariffs alone could drive the price of the iPhone 16 Pro Max 1TB — currently $1,599 (Rs 1.37 lakh) — up to nearly $2,300 (Rs 1.97 lakh). And that’s before the

US-China trade war escalation went into overdrive.

But, as some noted, it seems unlikely that Tim Cook would even consider moving all of Apple’s manufacturing to the US, considering Trump’s flip-flopping on tariffs.

With inputs from agencies