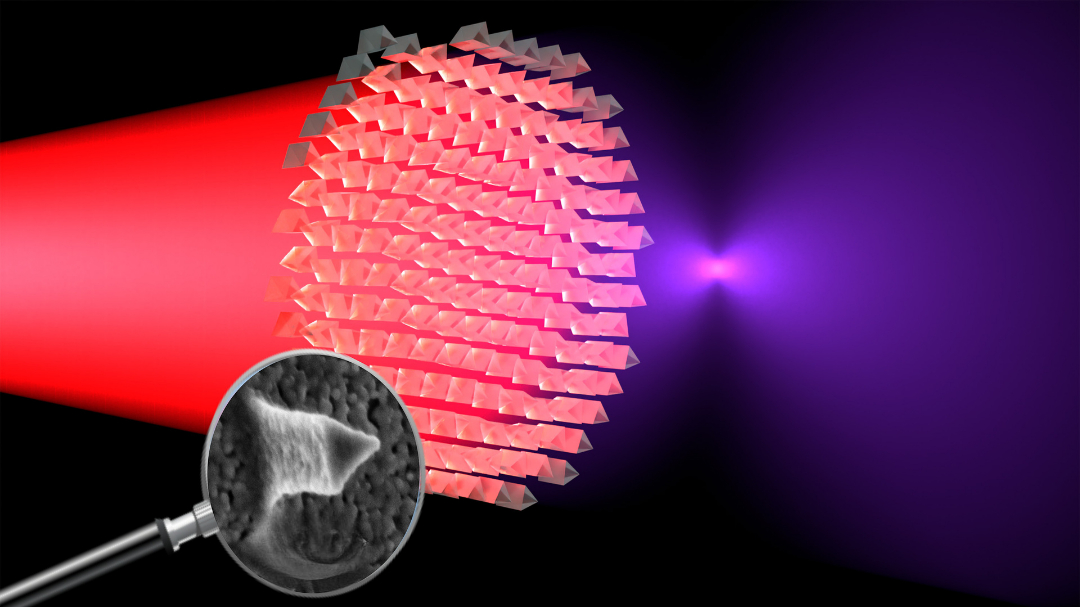

Scientists in Switzerland have developed an ultra-thin metalens that converts invisible infrared light into visible light by halving its wavelength, using nanoscale patterns stamped into a special crystal material called lithium niobate.

Led by Rachel Grange, an associate professor in the field of integrated optics and nonlinear nanophotonics at ETH Zurich, the team of researchers bent and transformed light in a way previously thought impossible with lenses 40 times thinner than a human hair.

This, in turn, paves the way for the creation of compact, high-performance optical components that could potentially be used as security features on banknotes or in the fabrication of ultra-thin elements for cameras.

The new lens can reportedly focus light just like a traditional glass lens, and cut the wavelength of the incoming light in half, effectively shifting infrared light into the visible spectrum.

According to the research team, this advancement could enable infrared-based technologies, including night vision and thermal imaging, to become significantly smaller, more affordable, and easier to use.

Rewriting infrared rules

Made from lithium niobate (LiNbO3), a metal-oxide material used in telecommunications to convert signals between electronic and optical formats, the breakthrough lens relies on a new method of shaping the material at the nanoscale.

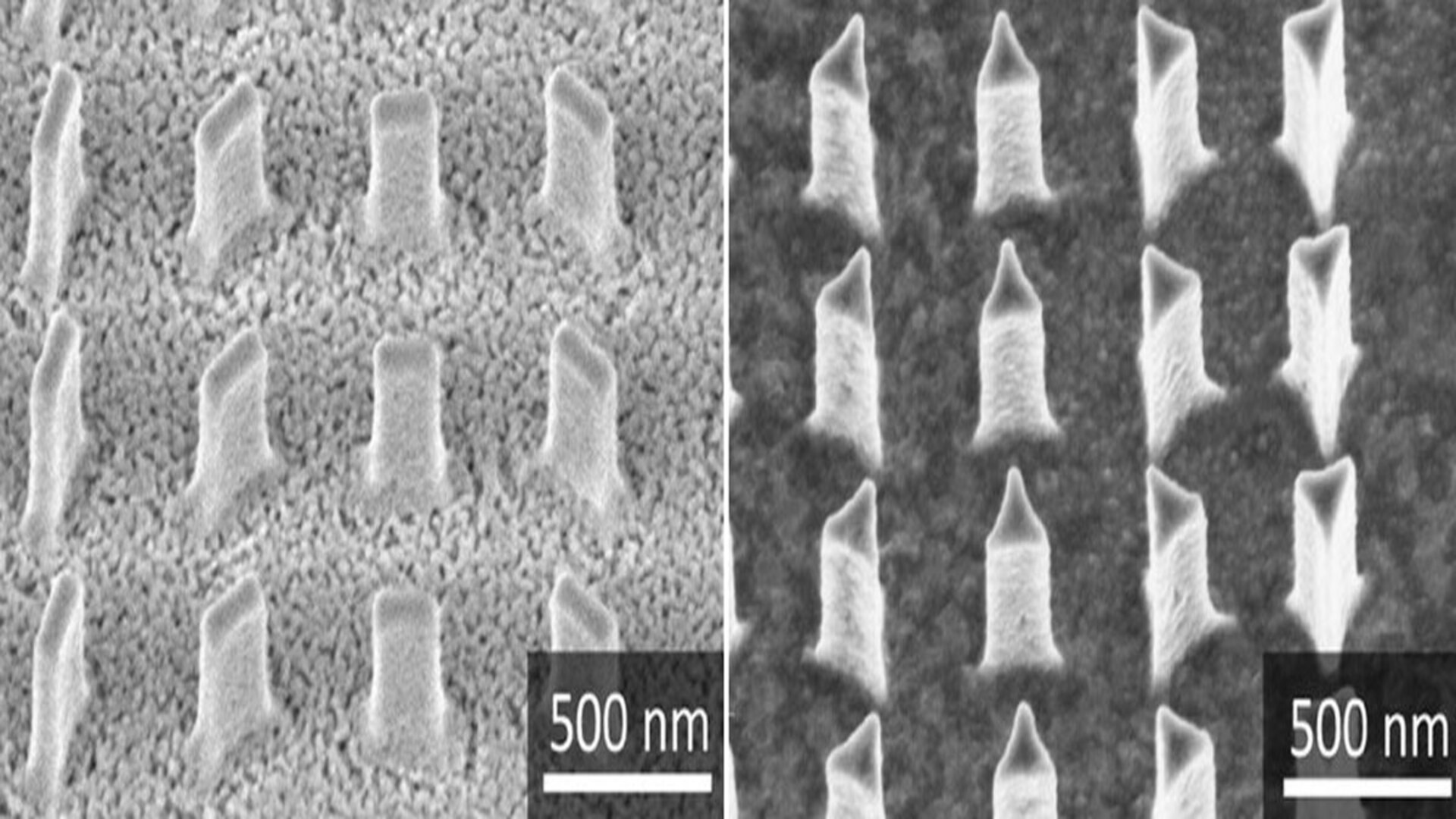

For the research, Grange and her team created a method that combines chemical synthesis with precision nanoengineering. “The solution containing the precursors for lithium niobate crystals can be stamped while still in a liquid state,” Ülle-Linda Talts, a doctoral student at ETH Zurich, said.

“It works in a similar way to Gutenberg’s printing press,” Talts continued, adding that once heated to 1112 degrees Fahrenheit (600 degrees Celsius), the stamped material solidifies into a crystal structure with unique optical properties.

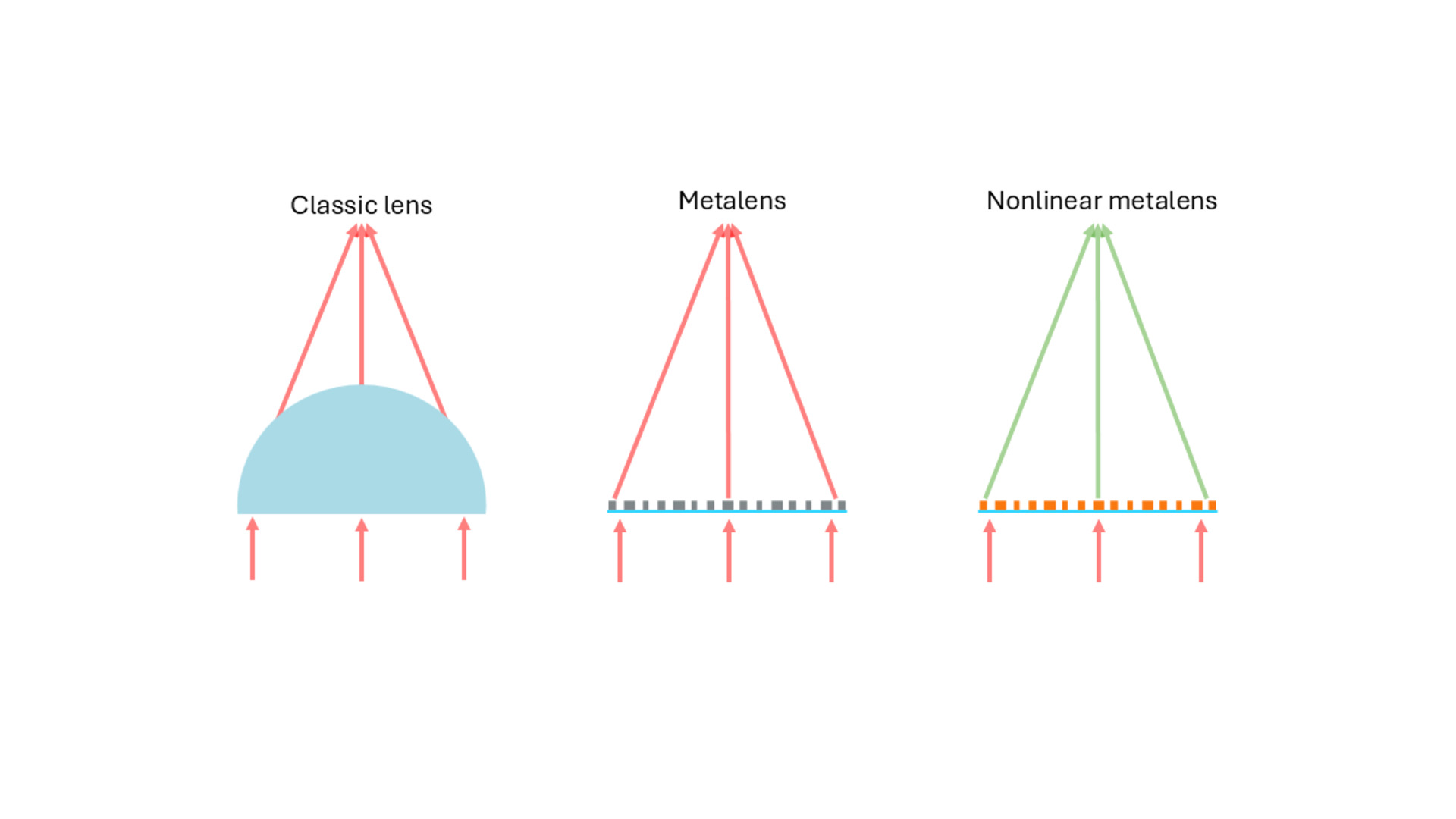

Schematics of a classic lens compared to a metalens.

Schematics of a classic lens compared to a metalens.

Credit: Ü. Talts / ETH Zurich

Producing lithium niobate nanostructures is challenging with conventional methods due to the material’s exceptional stability and hardness, however according to the technique is well-suited for mass production, as the reusable inverse mold makes fabrication faster and more cost-effective.

Lab experiments carried out by Grange and her team demonstrated that the lens could take infrared laser light at 800 nanometers and convert it into visible violet light at 400 nanometers, focusing it to a single point. The light conversion is based on a nonlinear optical effect, which until now required bulky crystals and complex setups.

A breakthrough solution

The researchers pointed out that that the technology could be used across many industries. For instance, the metalenses as well as similar hologram-generating nanostructures could serve as security features on banknotes, using their unique structure and light-conversion properties to help verify authenticity.

According to the team, the technology could make deep-UV lithography equipment simpler and more efficient for building next-gen semiconductors in manufacturing, and lead to smaller and more powerful imaging systems in science and medicine.

Microscopic image of different nanostructures as used in metalenses.

Microscopic image of different nanostructures as used in metalenses.

Credit: Talts ÜL, et al, Adv. Mat., 2025

Grange emphasizes that the development of ultra-thin optical elements, known as metasurfaces, is a relatively new area of research, emerging at the intersection of physics, materials science, and chemistry.

“We have only scratched the surface so far and are very excited to see how much of an impact this type of new cost-effective technology will have in the future,” Grange concludes in a press release.

The study has been published in the journal Advanced Materials.