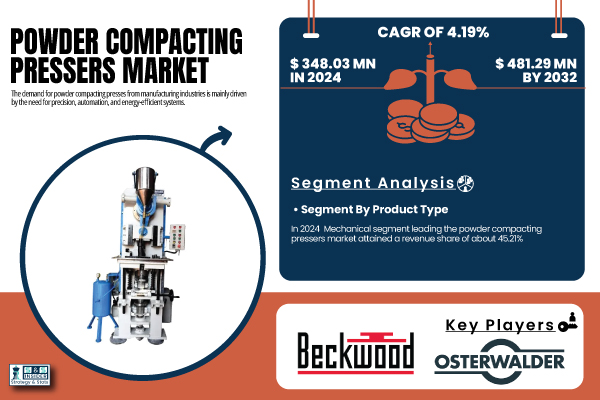

Austin, July 22, 2025 (GLOBE NEWSWIRE) — The powder compacting pressers market size was valued at USD 348.03 Million in 2024 and is expected to reach USD 481.29 Million by 2032, growing at a CAGR of 4.19% over the forecast period of 2025 2032. An increase in demand for precision-engineered components from the automotive, aerospace, medical, and industrial sectors is expected to boost the demand for Powder Compacting Pressers Market. Adoption of the combination of hybrid systems with AI-driven servo-hydraulic drives is accelerating this growth, providing energy-efficient production and repeatable part quality. Compact presses designed to cater to the new-age powder metallurgy application landscape are witnessing high demand from emerging markets that are industrializing quickly and expanding their manufacturing bases.

The U.S. powder compacting pressers market size was valued at USD 84.84 Million in 2024 and is expected to reach USD 108.81 Million by 2032, growing at a CAGR of 3.21% over the forecast period of 2025 2032. Drivers include automation uptake, demand for precision powder metallurgy parts, and pressure to enhance energy and material efficiency in compacting processes.

Gain Access to Powder Compacting Pressers Market Trends: Request Your Sample Report @ https://www.snsinsider.com/sample-request/7843

Key Companies:

- Komage Gellner Maschinenfabrik KG

- SMS group GmbH

- Osterwalder AG

- Maschinenfabrik Lauffer GmbH & Co. KG

- Gasbarre Products, Inc.

- Ajax CECO Erie Press

- Beckwood Press

- Digital Press

- DORST Technologies GmbH & Co. KG

- Cincinnati Incorporated

Powder Compacting Pressers Market Report Scope:

• Growing Integration of Smart Manufacturing and IoT Drives the Expansion of Powder Compacting Pressers Market Share.

Get In Touch for Personalized Insights on the Powder Compacting Pressers Market Report, Inquire Now @ https://www.snsinsider.com/enquiry/7843

Mechanical Presses, Powder Metallurgy, and Automotive Sector Drive Dominance in Powder Compacting Pressers Market in 2024

By Product Type

In 2024, the Mechanical segment dominated the Powder Compacting Pressers Market with a revenue share of approximately 45.21%. While mechanical presses are known for durability and speed in high-volume applications, that leadership is partly due to their established track record for ruggedness, reliability, and cost-feasible operations over the years. These presses are primarily used in mass production and high production environments where parts are intensely manufactured, based upon repeated, uniform cycle compaction, e.g., automotive or industrial component production. Coupled with lower operational and maintenance costs and ease of user control, they have become the manufacturer choice.

By Application

The Powder Metallurgy segment emerged as the leading application area in the Powder Compacting Pressers Market in 2024. The dominance is mainly attributed to the wide range of applications due to using powder metallurgy methods for the production of complex and lightweight parts in industries. It is particularly useful in the manufacture of automotive gears, bearings, bushings, structural parts, and electrical contacts when precision, material utilization, and cost control are essential. Low-waste manufacturing based on powder metallurgy is very much in line with current sustainability trends and enables the production of high-strength parts with very little post-processing. The growth of powder metallurgy as the leading application in the powder compacting presser’s market was mainly driven by the rise in demand for lightweight & high-performance components in automotive & aerospace industries.

By End Use

In 2024, the Automotive sector held the highest revenue share in the Powder Compacting Pressers Market, due to increase adoption of powder metallurgy in electric vehicle (EV) and hybrid vehicle manufacturing. EV drivetrain gears, transmission parts, magnetic cores and other components require high strength, precision, and durability characteristics that powder compacting technology is capable of delivering. As people turn their attention toward lightweight vehicle production and energy efficiency, automakers continue to utilize powder-compacted parts for weight savings without sacrificing any performance. In addition, the growing availability of EVs and the expanding e-mobility infrastructure came in very handy in terms of providing a major demand boost.

North America Leads Powder Compacting Pressers Market in 2024, While Asia-Pacific Emerges as Fastest Growing Region by 2032

In 2024, North America held the largest revenue share in the global powder compacting pressers’ market at approximately 34.56%. This leadership is due to established industrial base, early adoption advantages of advanced manufacturing technologies and the high demand of precision powder metallurgy components in automotive, aerospace, and medical sectors. The increasing demand for energy-efficient and throughput compacting pressers has led U.S. manufacturers and end users to integrate hybrid and servo electric compacting pressers, amidst sustainable quality and environmental standards.

Asia Pacific currently has the fastest CAGR by value at 5.55% during 2025 2032, due to its rapid industrialization, increasing manufacturing base, and high demand from emerging markets, such as China and India. The growing automotive and electronics hub in these nations is opening new avenues that increase the demand for powder compacting pressers specifically designed to mass produce automotive components and consumer electronic parts. Competitive labor costs and favorable governmental incentives lead upgradation of existing equipment and adoption of hybrid and electric press technologies. Demand for highly precise and automatic presses is also spurred by an increase in medical and aerospace manufacturing in the area.

Buy Now Full Insights Report on Powder Compacting Pressers Market 2025-2032 @ https://www.snsinsider.com/checkout/7843

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company’s aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.