A new method for achieving ultrafast, frictionless levitation has been developed by Japanese researchers at Yokohama National University, offering a transportation breakthrough that facilitates the transportation of miniaturized technologies, including mechanical, electronic, chemical, and biomedical products.

Friction is a major limiting factor in transport systems, such as conveyor belts. The novel levitation technique developed by the Yokohama team aims to eliminate this limitation, allowing for an increase in both speed and precision when moving small items.

The new levitation device is also untethered, allowing for objects to move in all directions with great agility.

Testing a Levitation Device

Extensive experiments confirmed that the device delivers complete friction mitigation, matching the theoretical principles behind its design. In initial tests without the device powered on, an object on a 10° incline slid down the slope at a rate consistent with gravity.

Once activated, the device propelled the object at a speed of three meters per second, demonstrating its effectiveness.

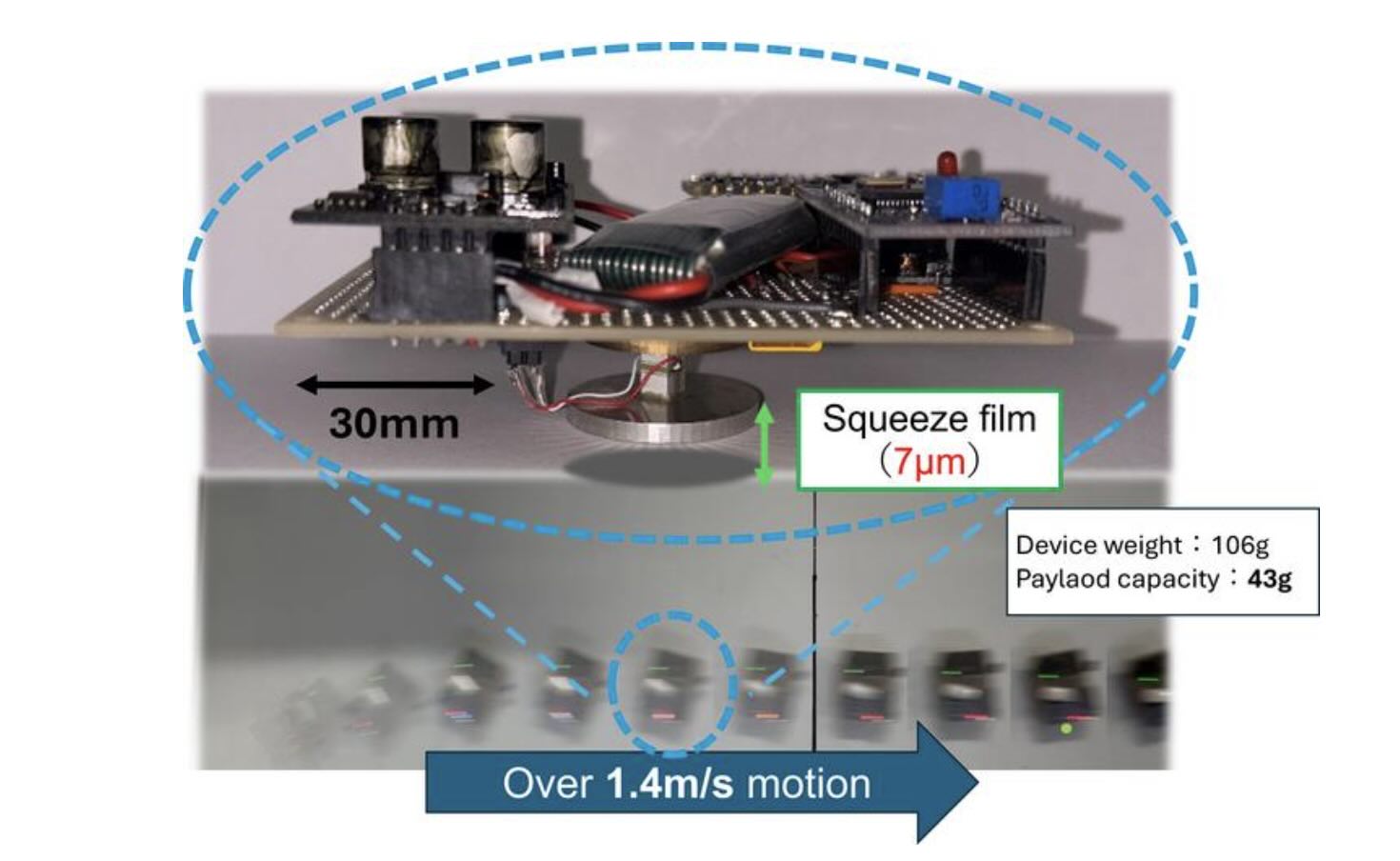

The team then tested the device with added loads. They found that when the combined weight of the device and its load was under 150 grams, it could achieve stable, frictionless levitation. This left roughly 43 grams as the maximum load before the system became overburdened and lost its levitation capability.

The Yokohama team’s frictionless levitation device is capable of ultrafast speed omnidirectional movement. Credit: Yokohama National University

The Yokohama team’s frictionless levitation device is capable of ultrafast speed omnidirectional movement. Credit: Yokohama National University

Acoustic Levitation

Unlike magnetic or pneumatic levitation, which require bulky external equipment, the Yokohama team’s device uses acoustic levitation—harnessing sound waves to suspend objects. This choice helped maintain the compact form factor needed for miniaturized applications. The main drawback of acoustic systems—cables that interfere with positioning—was overcome by integrating a wireless drive circuit.

“While acoustic levitation removes floor friction, conventional systems rely on cables that disturb positioning. We solved this by developing an untethered levitation device with a wireless drive circuit, enabling stable levitation height and high-speed, flexible transport,” said co-author Ohmi Fuchiwaki, associate professor and researcher at Yokohama National University.

Further Transport Innovations

Another key feature of the device’s design is its piezoelectric actuator, which converts electrical energy into mechanical energy. This actuator generates a thin “squeeze film” of fluid between two surfaces, allowing for frictionless, omnidirectional movement without the need for external cables or tethers.

The team has identified its next focus areas for improving the levitation device, with the intention of bringing it from the laboratory into routine use. The primary goal will be to enhance the efficiency of levitation in general by addressing two specific problem areas: load stability and performance on irregular surfaces, which remain significant obstacles to using their device in real-world scenarios.

Once these issues are ironed out, the team has an even larger goal: developing a robot capable of providing contactless delivery services. Such a robot would contain multiple of their levitation devices, supported by a propulsion system to push the frictionless agent along.

Overall, the team envisions that such technology could potentially be very useful, especially in the transportation of delicate items such as biomedical cells or other small components.

The paper, “Ultrafast Untethered Levitation Device Utilized Squeeze Film for Omni-Directional Transport,” appeared in Advanced Intelligent Systems on July 10, 2025.

Ryan Whalen covers science and technology for The Debrief. He holds an MA in History and a Master of Library and Information Science with a certificate in Data Science. He can be contacted at ryan@thedebrief.org, and follow him on Twitter @mdntwvlf.