Traction batteries lose performance after years of use, but many retain 70 to 80 percent of their capacity. That may not be enough for vehicles, but it is still too valuable to waste. A new project in Germany aims to give these batteries a second life instead of shredding them.

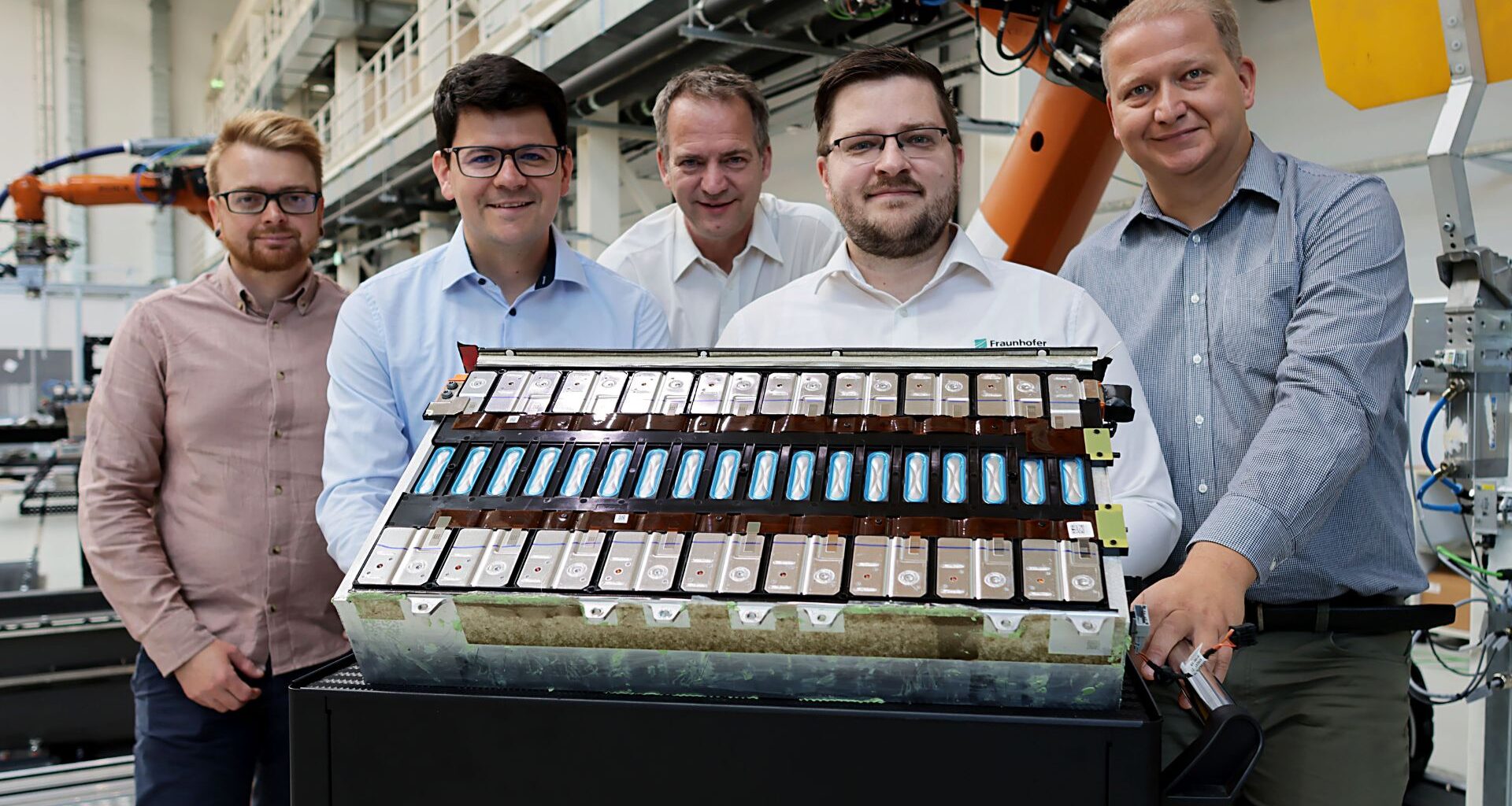

Dr. Rico Schmerler and his team at Fraunhofer IWU, in partnership with EDAG Production Solutions, are leading the work. They want to repair and remanufacture used traction batteries so cells can serve in large storage systems for homes, businesses, or utilities.

Shredding high-voltage storage systems discards valuable resources. The team sees disassembly and reuse as a better option.

By preserving materials, they can extend the life of components and cut reliance on energy-intensive new production.

The need for such solutions is urgent. By 2030, the number of used batteries in the EU will rise more than tenfold. Simple recycling or shredding will not keep pace.

Processes that allow careful disassembly down to the cell level are necessary. This approach makes it possible to replace faulty or degraded cells while continuing to use the healthy ones.

The planned pilot plant in Chemnitz is a direct response to this challenge. It will act as a demonstration of how second-life batteries can be put to use.

The process preserves raw materials and allows non-reusable cells to be passed on to recyclers, who can still recover lithium, cobalt, and other critical elements.

Automated dismantling and analysis

Fraunhofer IWU and EDAG are building the Chemnitz facility with a focus on automation. The plant will handle various high-voltage storage systems with an AI-supported dismantling process.

This ensures safe, efficient, and economical treatment of a wide range of battery designs.

A core element of the project is an integrated system to check the “state of health” (SoH) of every module and cell.

Only components with confirmed performance will reenter service. Fully intact modules can even be reused in new traction batteries, adding more value.

Traditional shredding methods often destroy cells that still have capacity. The Chemnitz approach aims to prevent this loss. Automated disassembly reduces risks for workers and standardizes the process, making it suitable for large-scale adoption in industry.

Data platform and workforce skills

The pilot plant is not only about hardware. It will also function as a data platform. Standardized information will help create consistent methods for battery recycling and reuse. The data gathered will support refinements in both disassembly processes and raw material recovery.

The project also addresses workforce needs. Battery dismantling requires skills that cross multiple disciplines. “Interdisciplinary knowledge in mechanics, electrical engineering, and computer science will continue to gain importance in many professions related to the automotive industry,” the institute said.

By combining second-life use, efficient recycling, and worker training, the Chemnitz plant aims to set a benchmark. It aligns environmental protection with economic value creation.

At the same time, it strengthens Saxony’s position in the European battery supply chain.

The project highlights a shift in how the industry views used batteries.

Instead of seeing them as waste, Fraunhofer IWU and EDAG want to treat them as assets. That approach could shape the future of sustainable energy storage across Europe.