X-ray imaging is a widely used technique in medical, industrial, and scientific fields. However, conventional X-ray imaging relies on the difference in attenuating power of the sample when X-rays pass through it, which gives limited contrast in objects with similar attenuation coefficients, such as soft tissue in medical imaging. In contrast, X-ray phase contrast imaging is a category of methods sensitive to the refraction rather than the absorption of X-rays as they pass through the sample. Coherent refraction, on features that can be spatially resolved, enhances image quality in low-density materials, particularly at high resolution. Stochastic refraction on multiple interfaces, the so-called dark field, has been shown to provide high diagnostic potential in various fields, such as breast, bone, and lung imaging1,2,3,4,5,6.

X-ray grating interferometry (XGI) is one of the methods sensitive to refraction7,8,9. Because X-ray detectors only measure the intensity of the beam, which is directly linked to the beam attenuation, the coherent and stochastic refraction is measured in XGI utilizing a set of high-aspect ratio (HAR) gratings to modulate the signal into an intensity variation10,11. A Talbot-Lau interferometer8,12 is an XGI that uses three gratings: G0, G1 and G2. A phase-shifting diffraction grating G1 induces an intensity pattern of parallel lines, with a period of several micrometers, in the plane of G2. G2 is a periodically-opaque analyzer grating creating a low-frequency Moiré pattern, which is then resolved by the detector behind it. Because the effect only occurs if the X-ray source is sufficiently small, a second periodically-opaque (absorption) grating, G0, is placed in front of a high-power, large-spot source to create an array of narrow sources. For appropriate combinations of the grating separations and pitches these narrow sources can be made to produce parallel-line patterns that coincide in the G2 plane, thereby maintaining and reinforcing the Moiré pattern.

The complex index of refraction of a material is expressed as \(n = 1 – \delta + i \beta\) where \(\delta\) and \(\beta\) describe the shift in phase and the attenuation of the beam, respectively. The complex refractive index imposes a phase shift on the wavefront when propagating through an object, with the gradient of the phase shift leading to a refraction of the beam by an angle \(\alpha\), which is directly related to the retrieved phase shift \(\phi\) of the phase stepping curve by7:

$$\begin{aligned} \alpha = \frac{p_2}{2 \pi d} \phi . \end{aligned}$$

(1)

Here, \(p_2\) is the pitch of G2, and d is the distance between the sample and G2. Therefore, the angular sensitivity in a Talbot-Lau interferometer increases with smaller grating pitches and longer distances between the sample and G2, as smaller refraction angles can be measured, which lead to bigger intensity changes on the detector13. Similarly, uncertainty in the measured signal \(\sigma _{\phi }\) propagates to uncertainty in the evaluated refraction angle using:

$$\begin{aligned} \sigma _{\alpha } = \frac{p_2}{2 \pi d} \sigma _{\phi }. \end{aligned}$$

(2)

The uncertainty \(\sigma _{\phi }\) for a photon-counting detector (absent a sample) is directly linked to14,15:

$$\begin{aligned} \sigma _{\phi } \propto \frac{\sqrt{2}}{V \sqrt{I}}, \end{aligned}$$

(3)

where V is the visibility (the contrast of the Moiré fringe measured on the detector behind G2) and I is the number of detected photons. Both V and I depend on the local quality of the gratings, including the geometry of the microstructures, the materials, and defects.

The design of an XGI system depends on several parameters that mutually influence the uncertainty of the measured refraction angle. Generally, small grating periods are targeted, as systems often have constraints on their total length. However, thicker gratings with taller Au-filled features are needed to efficiently block incoming X-rays, especially at higher X-ray energies. With insufficient height of the absorbing Au, the interferometer’s visibility is reduced. That said, as the aspect ratio of the features increases with increasing grating thickness and decreasing pitch, defects are more likely, leading to reduced visibility, heterogeneous visibility distributions, or unnecessary absorption of incoming photons that do not contribute to the interference pattern. The grating manufacturing technique determines the range of achievable aspect ratios. The two primary manufacturing processes for gold X-ray gratings used in grating interferometry utilize: Au-electroplating through an insulating polymeric template on an electrically conductive layer, as in Deep X-ray lithography and LIGA (Lithography, Galvanoforming, and Plastic Molding) (X-LIGA)10,16,17, or fabrication of an etched silicon template, such as by deep reactive ion etching (DRIE) of silicon18, followed by a bottom-up Au electroplating19. A more detailed description of the techniques is reported in the next section.

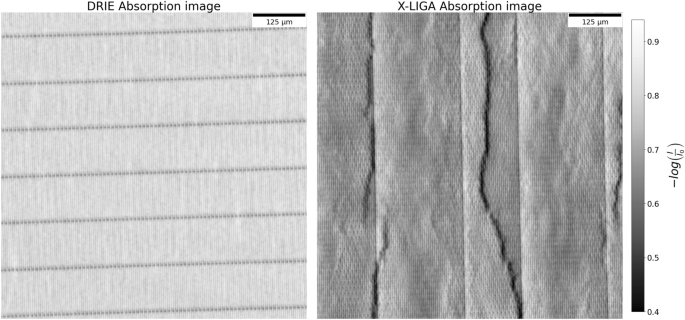

In this study, two pairs of grating sets were compared; the first set contained two X-LIGA gratings (MicroWorks GmbH), the second set contained two in-house manufactured DRIE and Au bottom-up filled gratings. All the gratings have a pitch of 4.2 µm. The X-LIGA gratings have a height of approximately 180 µm, while the DRIE gratings have a height of approximately 145 µm and 153 µm for G0 and G2, respectively. Both X-LIGA and DRIE gratings have comparatively widely spaced transverse line segments (bridges) to stabilize the high-aspect-ratio lamellae during the wet processes (development and electroplating for X-LIGA, electroplating for Au bottom-up of DRIE gratings). This work aims to analyze and understand the effects of the individual geometries and defects of the two grating fabrication techniques on the sensitivity of imaging systems incorporating them, defined as the inverse of Eq. 3 as \(S = \sqrt{I}V\). Previous work has shown the ability to obtain preliminary information about height and lamella inclination in individual gratings by angular X-ray transmission imaging.20. Here, an investigation of the limitations of these fabrication techniques and, eventually, their influence on an XGI system is presented. The work begins by analyzing the transmission profile of gratings produced by DRIE and X-LIGA using synchrotron imaging and studying their cross-sectional profile using scanning electron microscopy (SEM) and computed laminography (CL), respectively. This information is used to model the individual defects and predict their influence using wave propagation simulations. Finally, the gratings are mounted on a table-top Talbot-Lau interferometer and compared pairwise.