CATL’s rapid growth across Hungary, Germany, and Spain marks a major shift in how the company operates in Europe. It is no longer only supplying batteries from abroad. Instead, it is becoming deeply involved in Europe’s industrial and workforce ecosystem. Through new factories, training partnerships, and community programs, the company is building a long-term European presence that supports local economies and clean-energy goals.

Hungary: Debrecen Plant Nears Launch and Strengthens the EV Supply Chain

CATL’s new battery cell factory in Debrecen is moving into its final phase before full operation. The greenfield site is set to play a central role in Europe’s EV supply chain. When it opens, it will deliver 40 GWh of annual capacity, all of which is already fully booked by customers. Mass cell production is expected to begin in early 2026.

While the cell lines prepare for launch, module assembly has already been running for more than a year. The plant has produced more than 120,000 battery modules, enough to power over 30,000 electric vehicles across Europe. The number of employees is also rising quickly, and CATL expects the local workforce to reach 1,500 people by Q1 2026.

Matt Shen, Managing Director of CATL Germany and Hungary, said

“Our Debrecen investment is a major step towards strengthening CATL’s European presence. We are planning for the long term, bringing our most advanced and sustainable manufacturing technologies to Hungary.”

A Facility Designed for High Environmental Standards

Environmental protection is central to the Debrecen plant’s design. CATL built the facility to meet Europe’s strictest environmental requirements, along with additional Hungarian regulations. Several achievements highlight this commitment:

-

Energy use was reduced by almost 30 percent compared with the earlier IPPC permit.

-

Potable water demand cut to one-third, supported by water-saving cooling technologies.

-

ISO 14001 certification was achieved in October 2025, confirming strong environmental management.

-

Greening activities were launched around the site, improving local biodiversity.

CATL already operates ten carbon-neutral plants worldwide. The company expects Debrecen to reach carbon-neutral status within two years of opening, using renewable electricity and installing on-site solar capacity.

Building Local Talent and Creating a Stable Industrial Base

The battery giant has been hiring steadily since 2023. The Debrecen site now employs more than 1,000 people, with two-thirds coming from Debrecen and nearby regions. Recruitment covers a broad range of functions, including production, logistics, quality, finance, IT, and HR.

According to Alexandra Kitta, Head of Recruitment at CATL Debrecen, the company aims to create a modern and stable workplace with strong learning opportunities. CATL offers competitive salaries along with cultural and professional training programs. Employees also gain access to international expertise while building skills in advanced battery technology.

Strengthening Community Connections

Beyond manufacturing, CATL is investing in Debrecen’s cultural and social life. The company supports major local events and brings new traditions to the region, such as the Chinese Lantern Festival and the Mid-Autumn Festival. Community programs focus on children and environmental protection, reflecting its commitment to building long-term relationships with residents.

Germany: Developing Battery Skills Through Training, Industry Links, and the Dual System

Germany plays a major role in CATL’s European strategy. The company is investing heavily in workforce development, technology testing, and partnerships with educational institutions.

New IHK Certificate Course Builds Battery Expertise

At the end of 2025, CATL introduced the IHK-certified course “Basic Battery Technology for Trainees.” This two-week program gives second-year trainees foundational knowledge in areas such as battery safety, sustainability, cell manufacturing, and industry standards.

Nineteen trainees joined the first class. Over time, the course will open to participants from outside the company. Supported through the BatterieMD network, the program includes both hands-on training and digital learning modules that cover the full battery value chain.

This initiative is also an important step toward creating a dedicated battery-technology career path within Germany’s dual vocational system. Despite rising industry demand, Germany still does not have a standardized training track for battery specialists. CATL’s efforts could help shape a modern curriculum that combines theory and practice.

Expanding Testing Capacity in Thuringia

CATL’s training efforts support a growing physical presence in Thuringia. The company began battery cell production in Arnstadt in 2022, its first plant outside China. These cells now power high-performance European vehicles.

Simultaneously, it is also doubling the capacity of its large testing center, which is already certified by Volkswagen for both cell and module testing. The company has invested EUR 1.8 billion in its German operations and employs more than 1,700 people. Training programs focus on chemical processes, Industry 4.0 technologies, and workforce localization.

Deepening Training Partnerships

CATL runs a vocational training center at Erfurter Kreuz and collaborates with key partners, including TÜV Süd, IHK, Debrecen Vocational Training Center, University of Debrecen, and University of Miskolc. Dual study programs and in-house training help build a strong pipeline of skilled workers for Europe’s growing battery sector.

Spain: New 50 GWh LFP Gigafactory with Stellantis

CATL’s expansion reached another milestone with the groundbreaking of a new gigafactory in Zaragoza, Spain. The project is a 50:50 joint venture with Stellantis and will use lithium iron phosphate (LFP) technology. With a capacity of 50 GWh, the plant represents one of Europe’s largest battery investments to date.

Production is expected to begin in late 2026. When fully operational, the factory will supply battery packs for up to one million electric vehicles each year, helping cut more than 30 million tons of CO₂ over their lifetime.

The project includes an investment of up to EUR 4.1 billion and will create more than 4,000 direct jobs. Thousands of indirect jobs are also expected as suppliers and service providers expand around the site.

This gigafactory strengthens Europe’s battery value chain and reflects CATL’s evolution from supplying Europe to operating “in Europe, for Europe.” The Spanish plant will primarily serve Stellantis brands, while the combined Hungary and Spain operations will support a stable European customer base.

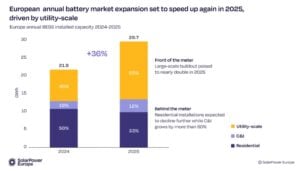

Europe’s Battery Storage Market Accelerates

Wood Mackenzie expects Europe’s battery storage capacity to climb from about 11 GW in 2024 to 16 GW in 2025, a 45% jump. The firm also projects steady growth through the next decade, with deployments rising at a 9% annual pace and reaching roughly 35 GW by 2034.

In this space, Germany will remain the largest market, supported by strong utility-scale and commercial demand. But the region also faces grid bottlenecks, more than 500 GW of connection requests, and rising revenue pressure as more projects come online.