The Boeing Factory in Everett, Washington, is the world’s largest building – spanning 98 acres – and it is so big it even created its own weather while it could fit Disneyland inside The massive building dwarfs the huge airliners outside(Image: Boeing)

The massive building dwarfs the huge airliners outside(Image: Boeing)

A colossal factory stretching across more than 472 million cubic feet holds the title of the world’s largest building – and it’s so vast that Disneyland could comfortably fit within its walls. The enormous Boeing facility in Everett, Washington dwarfs its closest competitor, the Tesla Gigafactory, by 33%. It has also churned out over 5,000 wide-bodied aircraft since opening its doors in 1967.

The mammoth site covers 98 acres of land. To put that into perspective, the original Disneyland resort in Anaheim, California, takes up roughly 85 acres.

The plant came into existence after Boeing’s then-President and Chairman William M. Allen realised a completely new type of manufacturing space would be needed to produce the groundbreaking 747.

The “jumbo jet” was approximately two-and-a-half times the size of the biggest passenger planes flying at that time.

Several locations for the enormous facility were evaluated, including one in California, but the 747’s chief engineer Joe Sutter had reportedly resisted placing the plant quite that far from Boeing’s Seattle headquarters.

The sprawling structure is large enough to completely contain Disneyland(Image: Boeing)

The sprawling structure is large enough to completely contain Disneyland(Image: Boeing)

The firm ultimately chose a disused military airfield situated just 22 miles from its main offices. Boeing’s initial structures at the location had been utilised to manufacture the legendary B-17 Flying Fortress bomber throughout World War 2.

The building work was finished in remarkably quick fashion, taking just over 12 months, with a price tag exceeding $1billion (£740million) – which actually surpassed Boeing’s entire value at that point, according to Airways magazine. Whilst modest building sites might feature just a skip or two, Boeing faced a mammoth task of shifting 4 million cubic yards of earth to construct the facility, requiring a purpose-built railway line to transport all the excavated material.

The outcome was a factory of such enormous proportions that Disneyland could easily slot inside. It even generated its own microclimate; during its early days, clouds would materialise beneath its 90ft-high roof due to moisture accumulation. However, modern air conditioning systems have now put a stop to this phenomenon.

Boeing 777 freighters and 777X airliners being readied for their eventual buyers(Image: POOL/AFP via Getty Images)

Boeing 777 freighters and 777X airliners being readied for their eventual buyers(Image: POOL/AFP via Getty Images)

Bonnie Hilory, executive director of the Future of Flight Foundation, described the factory to the local Everett Herald as Boeing’s “best product.”

She remarked: “I always tell people there’s one word to describe it and that’s scale. It’s just massive, with the biggest building, the biggest manufacturing and with giant aircraft inside of it.”

The already-colossal facility has seen two significant expansions: initially in 1978 to accommodate manufacturing of the Boeing 767, followed by another in 1992 for the substantially larger Boeing 777. More recently, supplementary structures have been constructed at the factory complex to support robotic assembly of the 777’s fuselage and production of the composite wing for Boeing’s latest 400-seat 777X.

In 2024, around 36,000 workers clock in daily at the massive 98-acre facility, operating across three primary shifts. But not everyone is directly building aeroplanes – some staff members are employed in the site’s own fire brigade, banking facilities, childcare centres, medical surgery or water treatment works.

The factory even has dedicated tour guides on the payroll to show visitors around.

Boeing Vice President and General Manager of the 777/777X program, Jason Clark, leading a press tour(Image: POOL/AFP via Getty Images)

Boeing Vice President and General Manager of the 777/777X program, Jason Clark, leading a press tour(Image: POOL/AFP via Getty Images)

These tours have proved incredibly popular, with 239,579 people shelling out $20 (£15) for the experience last year alone. David and Georgiana King, visiting from Sussex, have taken the tour on two occasions the first time a decade ago and again in May 2025.

“This place brought us out here,” David explained. “It was some of the same as last time but the 787 has been introduced since we were last here so it’s interesting to see how technology has changed.”

Whilst tourists are being shown the main production floor, Boeing staff can travel between different sections of the building without disrupting aircraft manufacturing by using an intricate network of underground passages stretching over two miles. More than a thousand bicycles are available to help them traverse these tunnels, and there are even several vans being driven around the complex.

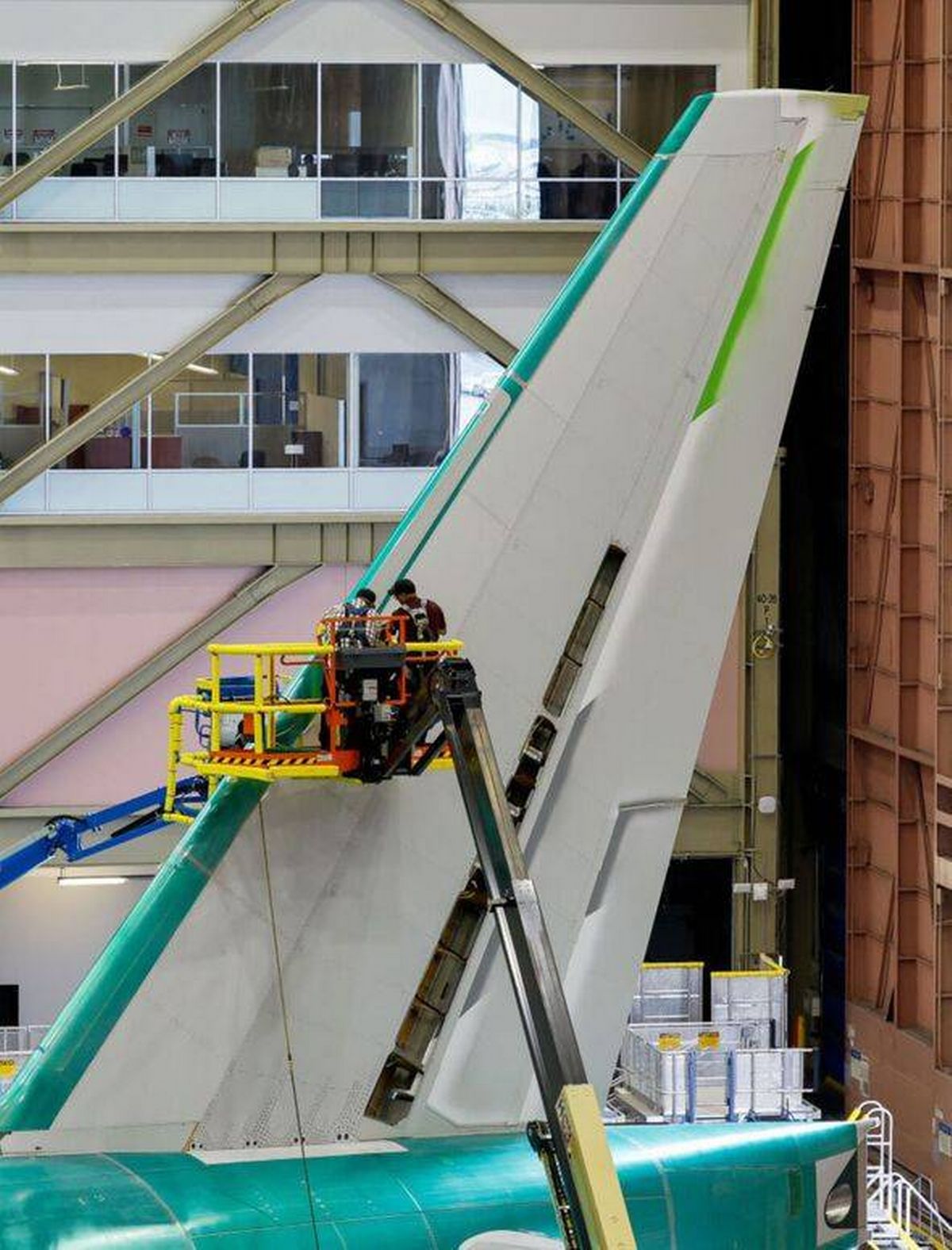

Boeing employees work on a 777(Image: POOL/AFP via Getty Images)

Boeing employees work on a 777(Image: POOL/AFP via Getty Images)

On ground level, there are 12 button-activated doors, with the biggest measuring 82 feet tall and 350 feet across. A fleet of 26 overhead cranes running along 31 miles of rails help manoeuvre the aircraft as they progress down the assembly line at an average pace of approximately 11⁄2 inches per minute.

The last leg of the construction process, which involves painting the completed aircraft, can take up to a week. A 747 typically needs around 454 litres of paint, while a 787 requires slightly less, approximately 370 litres.

It’s a meticulous and time-consuming operation. Boeing predicts that the first 777X will be ready for delivery to customers by 2027.

As of November 2025, there were 619 orders in total for both passenger and freighter versions of the 777X from a dozen customers.