A significant number of companies in the industry are operating at minimum capacity to maintain infrastructure

Ukraine’s energy system, designed during the Soviet era with enormous reserves to power industrial giants, has suffered critical damage. During the spring and summer shelling campaign of 2024, Ukraine lost more than 9 GW of generating capacity. For comparison, this is equivalent to the total consumption of several European countries. More than 50% of the country’s total generation capacity was destroyed or occupied, including Europe’s largest Zaporizhzhia Nuclear Power Plant (6 GW) and a number of key thermal power plants (Trypilska, Zmiivska).

Despite the heroic efforts of energy workers to restore power, the winter of 2025–2026 became the most difficult test. The January 2026 attacks on transmission substations and generation facilities led to the introduction of strict consumption limits, which in some industrial regions (Dnipropetrovsk and Zaporizhzhia regions) reached the level of emergency blackouts.

The National Bank predicts that the electricity deficit will continue until the end of 2026. This means that energy restrictions are becoming the “new normal,” which will hold GDP growth at -0.5% in 2026 due to this factor alone.

Concentration of industry

The extractive industry is geographically concentrated in regions that are most vulnerable to both shelling and network restrictions:

- The Kryvyi Rih basin. The heart of the iron ore industry. This is where the giants ArcelorMittal Kryvyi Rih and Metinvest Group’s mining and processing complex are located. The region regularly suffers from damage to high-voltage networks, which makes it impossible to transmit energy even when it is generated in other parts of the country.

- Dnipro-Zaporizhzhia hub. The center of the titanium and manganese industry. Its proximity to the front line (Nikopol district) makes the infrastructure vulnerable even to artillery shelling.

- Zhytomyr region. Center of titanium and granite mining. Although the region is in the rear, attacks on distribution networks lead to the shutdown of the Irshansk Mining and Processing Plant and hundreds of granite quarries.

The impact of the energy deficit on the industry is complex and is measured not only in hours of downtime, but also in billions in losses, loss of markets, and degradation of the technical condition of enterprises. Below is a detailed analysis by major sectors.

Iron ore industry

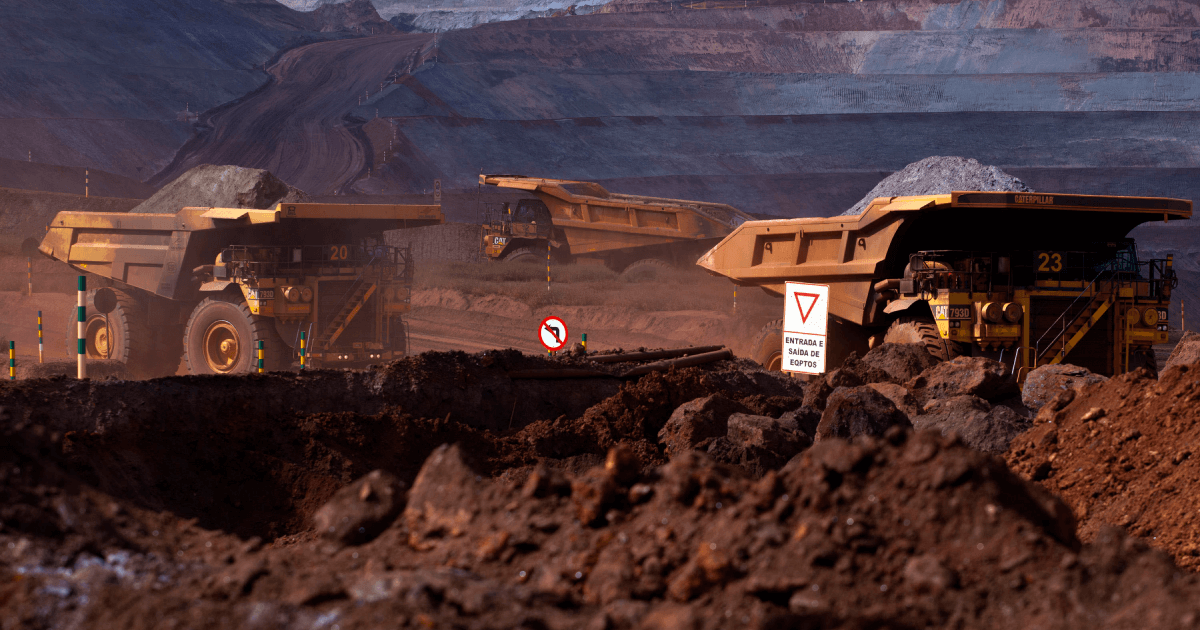

The iron ore industry is the most energy-intensive part of the mining sector. The processes of ore grinding, magnetic separation, flotation, and pelletizing require a continuous power supply of hundreds of megawatts. Data for 2025 and early 2026 show a dramatic decline in production due to the inability to ensure a stable energy supply.

- Ferrexpo. The company, which is one of the world’s leading exporters of pellets, has been hit hard. According to the production report for the fourth quarter of 2025, pellet production decreased by 47% compared to the same period in 2024, amounting to only 413 thousand tons. The production of premium DR pellets (raw material for green metallurgy) was completely halted (0 tons in Q4 2025) due to technological risks of sudden power outages. Total annual production fell by 9% despite demand on global markets.

- ArcelorMittal Kryvyi Rih. The largest foreign investor in Ukraine is operating at the limit of technical survival. As of 2026, the enterprise is operating at only 50% of its capacity. The planned steel output for 2026 is 1.9 million tons (compared to pre-war capacities of over 6 million tons). CEO Mauro Longobardo attributes this to unstable energy supplies and high tariffs. The mining department operates on a “fragmented” schedule, which leads to accelerated equipment wear and tear.

- Metinvest. Although the group is highly adaptable, it was forced to import coking coal to keep its blast furnaces running, which increased the cost of pig iron by $20–30 per ton. In January 2026, after another wave of attacks, the group’s enterprises switched to a mode of minimum energy consumption, necessary only to prevent man-made accidents.

A sudden power outage is a disaster for a mining and processing plant. Stopping a ball mill loaded with ore causes the pulp to solidify. To restart it, hundreds of tons of rock must be unloaded manually, which takes days. The shutdown of drainage pumping stations in deep quarries (up to 400 m deep) creates the threat of flooding and the loss of expensive equipment (excavators, dump trucks).

Titanium ore

In the first seven months of 2025, exports of titanium-bearing ores plummeted by 93.6% compared to the previous year, amounting to a meager 277 tons. In monetary terms, the decline was 93.1% (to $496,000). This effectively means a halt in exports of strategic raw materials.

Since November 2025, the Irshansk Mining and Processing Plant (Zhytomyr region) has been operating only in critical infrastructure support mode. The Vilnohirsk Mining and Processing Plant (Dnipropetrovsk region) has reduced production by 30–40%.

Graphite

Ukraine has historically been one of the world’s top five leaders in natural graphite reserves. The main and only player in this market was the Zavallivsky Graphite Plant, which had been operating continuously since 1934.

The events of 2024–2025 led to its shutdown, which was a landmark signal of deindustrialization. The shutdown of the enterprise is the result of a “perfect storm” that combined internal energy problems and external market pressure:

- The process of enriching graphite ore (flotation, drying, grinding) is extremely energy-intensive. A three- to fourfold increase in electricity tariffs has made the cost of Ukrainian graphite uncompetitive. The company’s outdated infrastructure, which has not been modernized for years, has prevented it from quickly adapting to new energy prices.

- China, which controls over 70% of the global graphite market and almost 90% of processing for anode materials, pursued an aggressive dumping policy in 2024–2025, saturating the market with cheap raw materials. This led to a collapse in global prices to a level below the break-even point for Ukrainian producers.

The shutdown of the Zavallivsky plant led to a radical change in Ukraine’s status in the graphite market. Whereas the country had previously been a net exporter, statistics for 2024 showed a shift to import dependence: exports amounted to only 2.87 thousand tons (remnants from warehouses), while imports began to grow.

Other extractive assets

Most granite quarries (approximately 200 special permits in Ukraine) have switched to diesel generation. The cost of a kilowatt-hour from a generator is 3–4 times higher than from the grid, which has led to an increase in the cost of crushed stone.

Unlike small manufacturers of building materials, the cement industry is showing some resilience thanks to the consolidation of capital by large players. Here, too, there are worrying trends indicating that production capacity is approaching its ceiling.

There is a critical gap between current capacity and projected reconstruction needs. The optimistic forecasts for 2022, which predicted the rapid start of large-scale reconstruction, were based on the assumption of resource availability. The reality of 2025–2026 shows that in order to achieve the required production level of 12–15 million tons per year, the industry needs years of modernization and a stable energy supply. A 67% increase in electricity tariffs in 2025 has significantly reduced the investment attractiveness of capacity expansion.

The loss of control or destruction of enterprises in the east and south of the country (particularly in areas of active combat) has changed the logistics map. Cement, as a heavy and cheap product, is sensitive to transportation costs. Rising rail tariffs and port blockades are putting additional pressure on the final price for the consumer, making Ukrainian cement less competitive even on the domestic market compared to potential imports from Turkey or Romania.