10

In a series of recent updates from Relativity Space, the company highlighted progress on its upcoming Terran R launch vehicle and supporting infrastructure for the rocket’s first flight, scheduled for 2026. The company is currently concentrating on three key areas: Terran R launch infrastructure, Aeon R engine testing, and the production of Terran R.

Block 1 of Terran R, the first version of the vehicle, is designed to teach Relativity how to successfully and efficiently recover the first stage before Block 2 ultimately takes over. With an annual flight goal of 50-100 flights per year, Relativity is relying heavily on the rocket’s reusable nature to enable regular flights and lower costs. The company believes that demand is outpacing the market, and is working to fill some of the gaps within the market with Terran R.

Measuring 86.6 m in height and 5.4 m in diameter, Terran R is expected to lift a maximum of 33,500 kg to low-Earth orbit (LEO) when expended, 23,500 kg when reused to a 200 km LEO, 20,000 kg when reused to a 400 km LEO, and 5,500 kg when reused to geostationary transfer orbit (GTO).

LC-16 infrastructure continues to rise

Relativity has been developing Launch Complex 16 (LC-16) at the Cape Canaveral Space Force Station in Florida since January 2019. After supporting the only flight of the company’s Terran 1 rocket, Relativity has been busy converting the site to support Terran R operations.

Recently, the foundation of the horizontal integration facility was poured along with many other concrete areas around the pad. Pipes were also installed for the expansion of the pad’s fluid systems, including water, liquid oxygen (LOX), and liquid methane (LCH4) fuel lines.

In March, the first propellant tanks of the tank farm were installed, the flame trench was excavated, and fabrication of the launch mount began. The first steel columns for the horizontal integration facility were raised in April, and the eastern flume wall of the flame diverter was recently installed. Next, the pad’s new water tower will be constructed to support the pad deluge systems, with foundation work currently underway.

Our launchpad is rising at Cape Canaveral’s LC-16, where Terran R’s future flights will lift off. Construction is progressing across key areas: the horizontal integration facility is underway, foundation work for the water tower is in progress, and the east flume wall of the… pic.twitter.com/wTQhPCTIDi

— Relativity Space (@relativityspace) June 12, 2025

The A-2 engine test site at NASA’s Stennis Space Center in Mississippi has also begun to undergo numerous upgrades and retrofits, preparing it for future Aeon R test firings.

See Also

Aeon R engine testing continues

Relativity has continually worked to ensure that the Aeon R engine operates reliably, with the goal of early reuse in the program. Terran R will utilize a total of 14 engines: 13 Aeon R engines on the first stage and one vacuum-optimized Aeon Vac engine on the second stage. As such, Relativity has a dedicated team at Stennis, where they have been regularly testing development versions of the Aeon R engine.

In March, it was announced that Aeon R had accumulated over 2,500 seconds of runtime, confirming it could withstand its reusable lifespan. The engine also achieved its longest burn yet in March, exceeding 160 seconds. In April, teams tested the engine’s thrust vector control capabilities that will control Terran R in flight. The engine achieved 5.5 degrees of motion, which is the maximum gimbal range allowed by the stand.

This, along with several upgrades, pushed Aeon R from development to qualification testing, which has seen the completion of its main combustion chamber and the injector assembly passing acceptance testing. With all the upgrades from the engine’s development applied, the qualification Aeon R engine was sent to Stennis Space Center.

Testing is locked in. 🤝 Our Aeon R qualification engine, built in Long Beach,CA has been activated at @NASAStennis and kicked off strong—with 11+ hot fires in May including a new internal record: 4 hot fires in under 10 working hours. pic.twitter.com/32VzSW81Sn

— Relativity Space (@relativityspace) June 11, 2025

This first qualification engine fired over 11 times in May and surpassed previous records by igniting the same engine four times in under 10 working hours. Relativity expects Aeon R qualification testing to be completed by the end of the summer. What’s more, the vacuum-optimized second stage engine, Aeon Vac, recently began manufacturing.

Terran R production in full swing

Following a major update at the beginning of March regarding the status of Terran R, the production of the medium-lift rocket has increased significantly.

Production of flight parts is underway, with the primary barrels and domes for liquid oxygen and liquid methane being manufactured, as well as the vehicle’s outer structures. This production is already being ramped up to support Terran R’s expected high-flight rate.

In March and April, the first stage of the first Terran R completed welding and passed inspection. The many composite overwrapped pressure vessels (COPV) utilized within Terran R were welded and cleaned before integration. On the second stage, the common dome and the LOX barrel were joined via the circumferential friction stir welder (CFSW) — the first time such a process had been completed for flight hardware. Relativity’s implementation of the CFSW on flight hardware will allow the company to significantly ramp up production of Terran R components.

In May, the first stage LOX dome was loaded onto the CFSW for its second weld. The second stage transfer tube was also welded, bringing the second stage close to completion.

In another effort to increase efficiency and decrease production times, Relativity began using automated drilling to drill thousands of holes on thrust structure panels. The company also introduced the first automated phased array ultrasonic testing (PAUT), which inspected the first flight CFSW weld. Another automated PAUT is currently being installed to support inspection of structural stringers, which are installed using a new horizontal friction stir welder.

While production of stage tanks and components was ongoing, hardware for Terran R’s avionics hub officially entered production.

Terran R production is ramping up. As we push toward first flight, manufacturing across our Long Beach factory is accelerating:

🔧 Key highlights from May:

– Automated drilling processed thousands of holes on thrust structure panels

– LOX dome loaded onto the CFSW for its next… pic.twitter.com/dqBPnIvhwC— Relativity Space (@relativityspace) June 10, 2025

The installation of PAUTs and CFSWs is just a piece of the upgrades Relativity is making to its production facilities to increase Terran R production rates. Relativity also acquired new dome flipping tools that simplify the mating of the tank sections, and a new vertical turning lathe was added to the production line to increase the production of new barrel and dome sections.

By April, the initial load tests on a prototype barrel section had been completed, confirming the structural models developed in the software. A new structural test stand was also completed for full-scale testing operations, and engine loading simulators were added in May.

As Relativity heads further into 2025, it is focused on completing the production of the first Terran R vehicle and completing critical infrastructure nationwide for the testing and launch of the rocket and its components. The first flight of Terran R is currently scheduled for the second half of 2026.

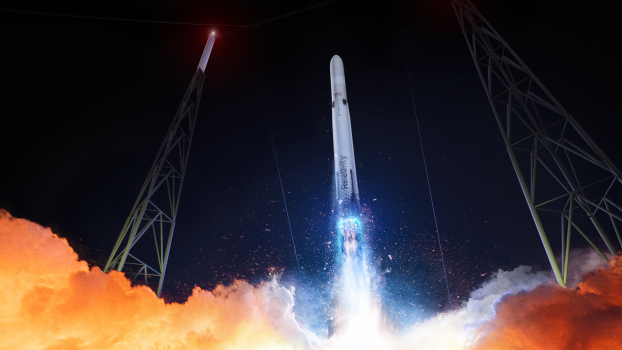

(Lead image: Artist’s impression of the Terran R launching from LC-16. Credit: Relativity Space)