For Dan Ovadya, CEO of FloraGen LLC, the future of controlled environment agriculture (CEA) doesn’t rest solely on advanced lighting systems or automation. It starts with something much more fundamental: the seed.

“There’s a ton of hype in the seed industry so we believe in robust trial designs and using quality data to make the best genetic selection for your farm.”

It’s a grounded insight from someone whose career has spanned more than 30 years in controlled environments, genetics, and breeding innovation. Today, FloraGen, an agtech company based in Davis, California, collaborates globally with breeding companies across all crop types, offering both strategic advisory services and proprietary technologies.

But Dan believes it remains important to stay connected to the biology. “Artificial intelligence may help you analyze seasonal fluctuations in night temperature but it will not grow your plants for you.”

The fundamentals of genetics in CEA

He emphasizes on not losing sight of the basics, especially when it comes to genetics.

“Even the smallest CEA farms should be trialling three to five genetics in-house,” he says. “It doesn’t matter if it’s lettuce, cannabis, or strawberry, you’ll see dramatic differences in performance just from the seed.”

FloraGen’s advisory arm works closely with breeding companies across vegetables, ornamentals, row crops, and cannabis. The focus: helping clients use accelerated breeding, precise phenotyping, and data-backed crop modeling to shorten timelines and improve outcomes.

“Breeding today is like mining for gold,” he explains. “You’re going through a lot of dirt to find the nugget of gold. The faster you screen, the more you get out. And we can now help clients run four generations of tomato in a single year.”

That speed isn’t possible without the right environment, and that’s where FloraGen’s second core area comes in.

Why climate still rules the equation

FloraGen has spent over 15 years building a detailed climate analysis platform, designed to help growers and investors make better decisions before they break ground on a facility. It’s a response to a recurring problem Dan sees in CEA: poor site and system design due to weak environmental planning.

“We look at 30-year temperature and lighting data averages to determine where the best place is to build a greenhouse, for whatever crop you’re trying to grow,” he says. “Too many people skip this step or do it in-house. Then they wonder why the greenhouse doesn’t hit the performance spec.”

The analysis doesn’t stop with macroclimate. FloraGen also uses crop modeling to provide highly specific targets for each crop’s ideal environment.

“Light is the number one driver of crop productivity. But ask ten people how much light a strawberry needs in a greenhouse, and you’ll get ten different answers. We give clients exact targets, including day temperature, humidity, and lighting, based on biological data.”

This applies to both commercial production and R&D settings. For breeders, it means the ability to test a variety’s genetic potential such as Brix level in tomatoes or sugar content in strawberries, under exact conditions.

Designing fluctuation into controlled systems

But what about replicating the real-world fluctuations that crops experience outdoors? When it comes to strawberries, infamously sensitive to light, temperature, and photoperiod, Dan says it starts with identifying the genotype.

“Strawberry is one of the most complex flowering systems in agriculture,” he explains. “You have day-neutral and short-day types, and each responds very differently to environmental cues.”

So how do you simulate fluctuating conditions in a greenhouse?

“You need to build a model around the specific variety and its reproductive triggers. Then we look at the farm’s own sensor data, light, temperature, and humidity, and use that to recommend improvements. It’s not a one-size-fits-all answer.”

Working with breeders: Trusting the data

One of FloraGen’s core services is supporting breeders in optimizing their trials, especially when making decisions that depend on small environmental differences.

“If you’re phenotyping 20 tomato varieties and you can’t trust your Brix data, the whole trial can lead you in the wrong direction. We provide advice on how to control your trial environment so the data is meaningful.”

Modern breeding is increasingly blending environmental manipulation with molecular tools. Ovadya helps clients use light, temperature, and even photoperiod tweaks to push flowering in slow crops like cabbage or broccoli.

“We’re able to force flowering, generate seed, and move the process along faster. That, paired with molecular breeding, is where the industry is heading.”

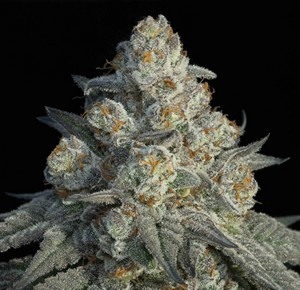

Cannabis as a complex but just another crop

Cannabis as a complex but just another crop

FloraGen also runs a substantial cannabis breeding programme, where it has developed a novel female-female breeding system and a sizable genetic library. Ovadya views cannabis through the same lens as any other complex crop.

“It’s just another crop in some ways. On the other hand, cannabis is tricky in certain ways, legally, genetically, operationally, but it’s also an opportunity to apply good science to a very unique consumer product.”

Despite speculation that the industry might shift toward seed-based production, Dan remains pragmatic.

“A lot of people said cannabis would move from clones to seeds, and I believed that too. But right now, clonal propagation is still very viable and profitable. I wouldn’t over-invest in trying to force that change.”

The consumer voice

Dan encourages breeders and growers to remain open-minded to consumer trends and continue experimenting.

“Most of the time, we trust that the client knows their market. But I always encourage them to trial new genetics and not just stay in the safe zone,” he says.

He points to innovations like baby kale in the U.S. or Sun World’s table grape varieties as proof that new products can shape entire markets if breeders are willing to explore.

“Even if you’ve grown the same lettuce for 10 years, there’s always something better out there. The question is: are you trialling it?”

For more information:

FloraGen

Dan Ovadya, CEO

[email protected]

www.floragentech.com