Each year, rivers pour some 37,000 cubic kilometers of fresh water into the oceans, releasing energy equivalent to 2.6 terawatts, roughly matching humanity’s total power use.

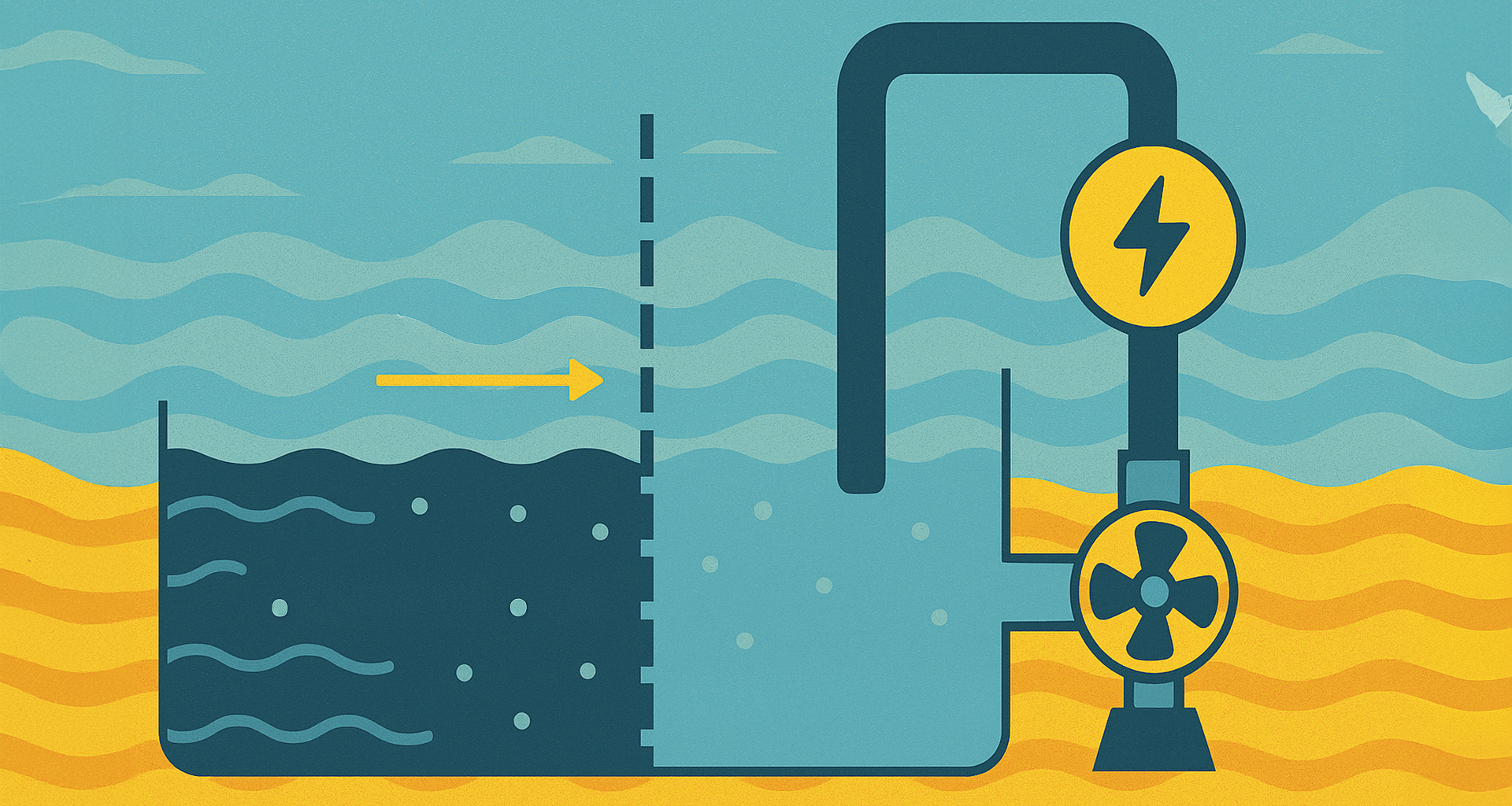

At these mixing zones, the meeting of fresh and salt water creates an osmotic pressure of around 26 bar, the same force you’d find behind a 270-meter waterfall. Engineers have long wondered: what if we could turn this quiet chemistry into electricity?

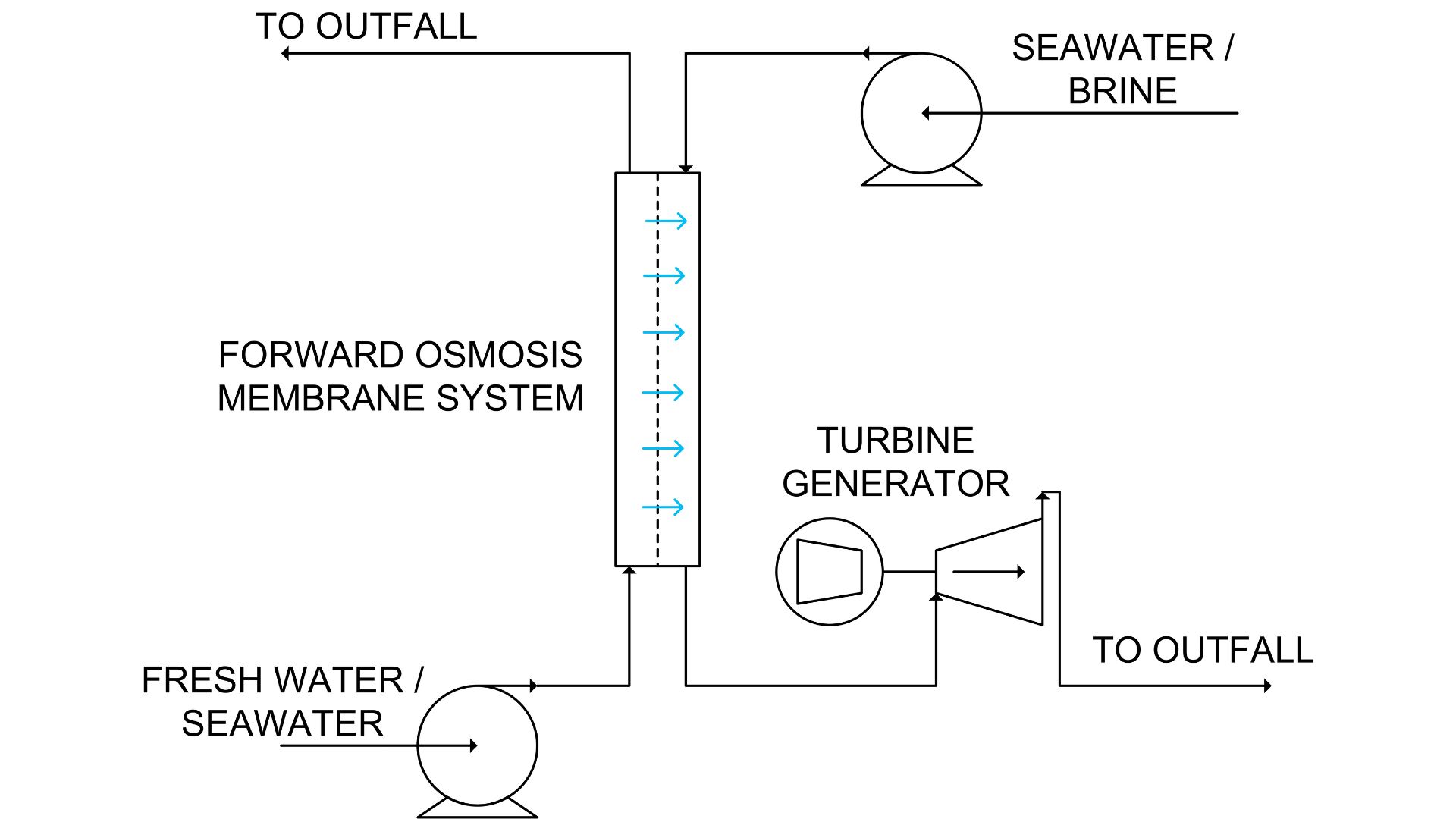

Pressure retarded osmosis (PRO) systems harness this technology by directing freshwater into pressurized seawater. This drives turbines as the volume of water expands.

The global coastline hosts thousands of kilometers of these natural mixing zones. Theoretically, osmotic power could generate up to 5,000 terawatt-hours of power annually. However, the gap between theory and reality is wide.

Commercial PRO systems must achieve at least five watts per square meter (W/m2) of membrane area to remain economically competitive. While some pilot installations have achieved 8 W/m², most current systems operate at 1 to 3 W/m².

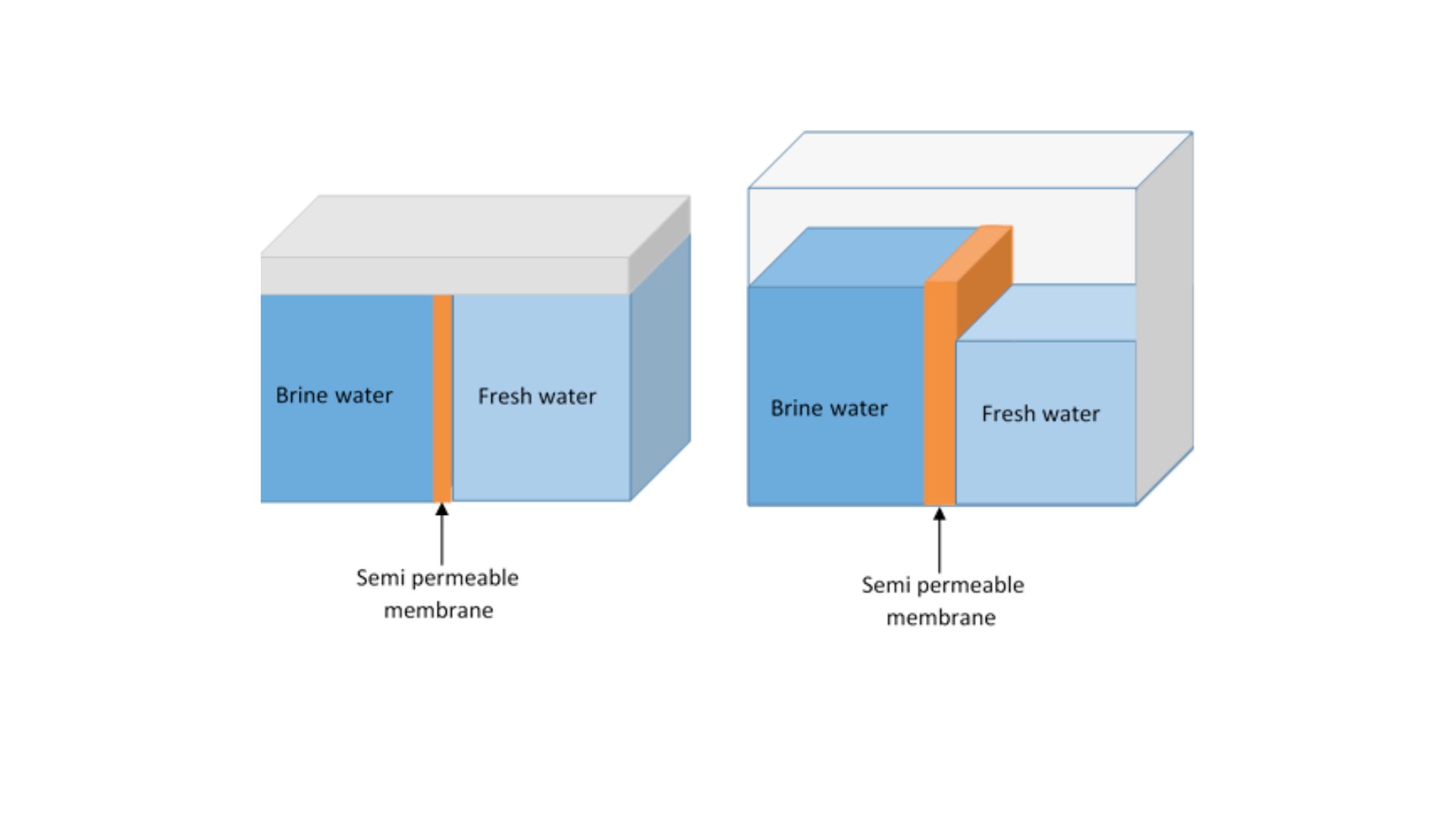

The basic principle of osmosis. Credit: Wikilakz/Wikimedia Commons.

The basic principle of osmosis. Credit: Wikilakz/Wikimedia Commons.

The challenge is controlling molecular-level water transport in environments where salt, algae, and microscopic organisms assault membranes, while the economics compete against rapidly declining solar and wind power costs.

At its core, the technology exploits salinity gradients between water sources.

Engineering electricity from salinity gradients

PRO systems work through osmosis, the process by which water molecules move from an area of low salt concentration to a high concentration across a semipermeable membrane.

Selective permeability takes over when fresh river water encounters pressurized seawater across a membrane. Water molecules migrate toward the saltier side, but the membrane blocks salt ions from passing. This creates serious pressure, 26 bars, waiting to be harnessed.

The membrane permits freshwater to enter the pressurized seawater chamber, expanding its volume. The mixture pushes through turbines that generate electricity.

The key to extracting maximum possible power from this process is the membrane. How much water passes through the membrane and at what pressure determines the electricity generated.

Today, thin-film composite (TFC) polyamide membranes are used in PRO systems. These act as a sieve for water molecules. When flow rates exceed their capacity, the membranes begin to fail.

PRO system design. Credit: Starsend/Wikimedia Commons.

PRO system design. Credit: Starsend/Wikimedia Commons.

Salt builds up at the membrane surface, like sediment in a pipe, reducing the effective pressure by 30 to 50 percent. Internal resistance from the membrane’s structure saps additional efficiency.

If lucky, this results in a system that can extract half the energy that is theoretically possible. So while osmotic power has potential, our current technology limits what can be extracted.

The membrane bottleneck

Most TFC membranes today can handle about 15-20 bar pressure before deforming. Push harder, and the delicate polymer layers compress, crushing the channels, allowing water through.

Biofouling poses an even messier problem. River water carries bacteria, algae, and organic matter that treat membrane surfaces like prime real estate. Within weeks, biofilms slash water flux by 20-40%.

Current solutions include using chloramine as a disinfectant, periodic backwashing to prevent biofilms from forming on the membrane, and air scouring. These methods work only temporarily and add cost and complexity to the process.

Engineers have tried hydrophilic coatings, zwitterionic polymers, and even UV treatment. But nature is remarkably persistent. If there’s a surface and nutrients, something will grow on it. The fouling problem worsens in warm climates, where biological activity peaks year-round.

Biofouling seen on an electric cable. Credit: Lamiot/Wikimedia Commons.

Biofouling seen on an electric cable. Credit: Lamiot/Wikimedia Commons.

The economics make these challenges harder to ignore. While solar and wind costs have plummeted below $0.03 per kilowatt-hour in optimal locations, osmotic power still faces projected costs of around $0.14—nearly five times as expensive. Membranes alone account for 30-40% of capital costs, and they need replacement every 3 to 5 years, if they last that long.

The Statkraft prototype that changed the field

Osmotic power is a young technology, with the first osmotic power prototype opening in 2009 in Norway with Statkraft. The facility located at Tofte, Hurum, promised to demonstrate PRO’s commercial potential. Four years later, the project was abandoned.

Statkraft achieved just 1 to 3 W/m² power output, far below the 5 W/m² threshold for economic viability. The 2-4 kW prototype faced high operational costs that prevented commercial viability.

Yet Statkraft’s failure provided crucial data. Engineers demonstrated that power density increased from less than 0.1 W/m² to close to 3 W/m² during their research period.

Most importantly, the prototype confirmed that the system could produce power reliably 24 hours a day, proving PRO’s technical feasibility—not its economic viability with 2009-era membranes.

Pathways to viability

The hybrid advantage

Rather than standalone plants, engineers increasingly see PRO’s future in hybrid systems.

Statkraft’s osmotic power plant prototype in Hurum, Norway. Credit: Bjoertvedt/Wikimedia Commons.

Statkraft’s osmotic power plant prototype in Hurum, Norway. Credit: Bjoertvedt/Wikimedia Commons.

Reverse osmosis (RO) is the process that drives water purification systems. An external high pressure is used to overcome osmotic pressure, forcing clean water through the membrane while leaving salt behind.

RO plants provide the perfect infrastructure match. High-pressure equipment is already installed, and the concentrated brine waste they produce enhances osmotic pressure. A PRO unit capturing energy from RO brine could recover 0.5-1.0 kWh per cubic meter of desalinated water, cutting net energy consumption by 20-30%.

The Public Utilities Board in Singapore pilots this method, and Japan examines PRO integration at coastal industrial locations where existing processes offer operational advantages.

Hybrid configurations avoid PRO’s highest barrier—upfront capital costs—by utilizing infrastructure already on site. The approach also addresses RO’s brine disposal challenge while producing powers.

Building a better membrane

Apart from the capital costs, the membrane technology also impacts commercial viability.

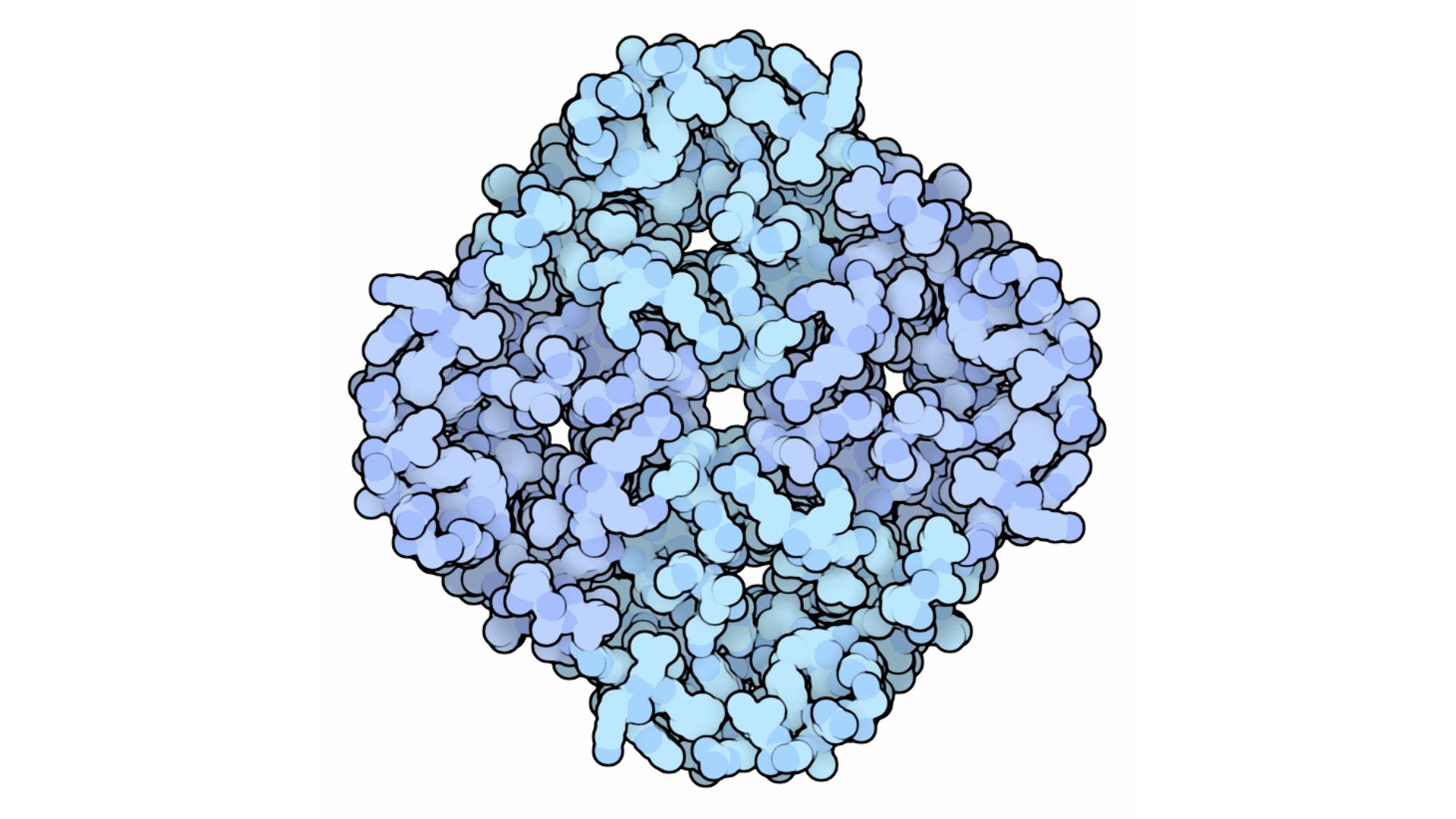

Engineers are turning to nature for inspiration, and aquaporins exemplify why. These specialized proteins—ubiquitous across living cells—serve as water channels, effectively filtering water.

Illustration of an aquaporin molecule. Credit: David Goodsell/Wikimedia Commons.

Illustration of an aquaporin molecule. Credit: David Goodsell/Wikimedia Commons.

Biomimetic membranes incorporating these proteins achieve water permeability an order of magnitude higher than conventional commercial alternatives. Danish company Aquaporin A/S is now scaling production of these aquaporin-based membranes, though costs remain high.

Near-term solutions focus on membrane architecture. By engineering support layer architecture, thin-film nanocomposite membranes counteract internal concentration polarization and salt accumulation within the membrane’s porous structure, reducing the driving force for water flow.

Laboratory studies have also shown that surface modifications using polyethylene glycol (PEG) reduce fouling.

Where osmotic power fits in the energy mix

In reality, osmotic power won’t replace solar or wind as a dominant renewable energy source. Integration emerges as the only viable trajectory.

Hybrid systems combining desalination plants and advanced biomimetic membranes overcome the cost and performance constraints that limited previous efforts, including Statkraft’s 2009 prototype.

For coastal cities and island nations, osmotic power offers something unique. Unlike other renewable sources of energy, which are intermittent, osmotic power runs 24 hours per day, independent of the weather.

As Japan’s recently opened facility, Denmark’s SaltPower facility, and Singapore’s testing demonstrate, the technology is moving from pilot testing to commercial deployment.

The question isn’t whether osmotic power works, but where it makes economic sense—and that answer increasingly points to places where salt water, fresh water, and existing infrastructure converge.