H2 Clipper, a company specializing in hydrogen-based transportation and infrastructure, has secured a patent for a breakthrough in aerospace manufacturing.

The newly granted patent covers the use of autonomous and semi-autonomous robotic swarms in large-scale aircraft and aerospace production.

Building on a foundational patent awarded in December 2023, the latest advancement allows for faster, more precise, and cost-effective manufacturing using swarm robotics, marking a significant step forward in autonomous aerospace technologies.

“The issuance of this patent marks a pivotal moment in the evolution of aerospace and aviation manufacturing. By replacing traditional assembly lines with robotic swarms, this breakthrough enables aircraft and large aerospace assets to be built faster, at a significantly lower cost, and with far greater precision,” said Rinaldo Brutoco, H2C Founder and CEO, in a statement.

Precision swarm assembly

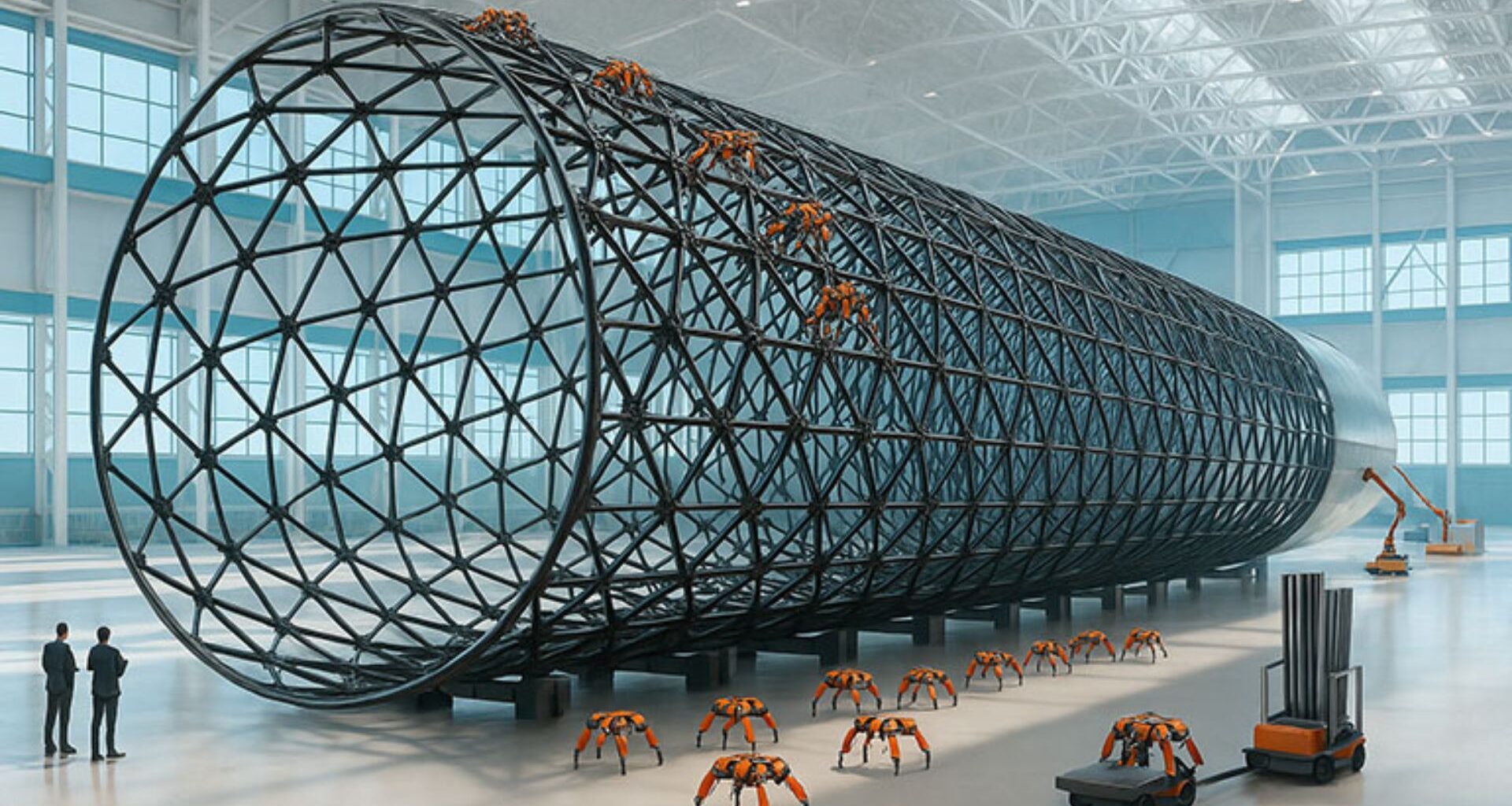

H2 Clipper’s newly patented system uses a swarm of smart robots to build large aerospace structures faster, more safely, and with less space needed. These robots work together like a team, each one handling different tasks such as assembling the aircraft frame, attaching the outer shell, installing parts inside, and checking the quality of the work as they go.

The system is powered by artificial intelligence (AI) and machine learning, which help the robots improve their work over time, reduce mistakes, and stay on schedule. The robots can also adjust their actions automatically to make sure everything fits perfectly.

According to the firm, safety is a big focus of the design. The robots use sensors and AI to avoid bumping into each other and to carry out risky tasks that would otherwise put human workers in danger, like working at high places. Because there are no fixed assembly lines or large structures needed, the system can be operated remotely and expanded to different locations easily.

Another key feature is the integration of heavy-lift robots, which can move and position large parts during the build. This means entire aircraft structures can be built in place, either upright or flat, reducing the need for large manufacturing facilities.

“Conservative estimates based on current aerospace production benchmarks suggest this approach can reduce total manufacturing costs by 40 percent or more, and cut production timeframes by up to 60 percent, while simultaneously improving quality,” said Brutoco, in a statement.

Sustainable aviation tech

H2 Clipper is the developer of the Pipeline-in-the-Sky, a hydrogen-powered airship designed for long-distance global transport without using fossil fuels. The company also created the H2C Safety Pipe, a system for safe, last-mile hydrogen delivery.

Since 2008, H2C has invested heavily in research, development, and patents covering modern airship design, advanced software, and midstream hydrogen delivery solutions.

Traditionally, building aircraft involves moving large parts through multiple stages across vast facilities, leading to high costs and complex logistics. H2C’s approach eliminates this by constructing large aerospace structures in place, reducing time, infrastructure needs, and operational overhead.

This shift inspired the company’s focus on swarm robotics, a smart, scalable solution originally intended for airship assembly but now recognized for its potential in broader aerospace manufacturing.

According to the firm, with its continuation patent now granted, it plans to bring together a select team of experts in aerospace, robotics, AI, manufacturing, and regulation to guide the technology’s next phase. This advisory group will help shape a roadmap for future development and explore licensing opportunities for major aerospace manufacturers.

H2C also envisions forming an industry consortium to drive the widespread adoption of Swarm Robotics across the aviation sector.