The Manchester Evening News was invited on a tour to mark 100 years of the chocolate digestive The chocolate in crumb form

The chocolate in crumb form

Like all great cities, Manchester has its fair share of landmarks. Old Trafford, the Town Hall, the cathedral, and even – whether we like it or not – the concrete block of the Arndale.

But we’re quite lucky in Greater Manchester to have a number of olfactory landmarks too – places where, if blindfolded, you could probably still tell where you are by the distinctive smell.

There’s the Kelloggs factory in Trafford Park, emanating its breakfast-y goodness over Barton Road and beyond. There’s the Heineken Brewery on Princess Parkway, its delicious malty scent wafting for miles around on breezy days.

But perhaps best of all is the McVities factory in Stockport.

Tour of the McVities Factory in Stockport

Tour of the McVities Factory in Stockport

The red-brick home of the Edinburgh-born biscuit makers has loomed large on the A6 ever since 1917, built to help the company keep up with demand for their Iron Ration biscuits included in soldiers’ emergency rations in WW1.

The brand, now owned by Yildiz, a Turkish food manufacturer, makes some of the country’s most beloved biscuits.

Their north London site is where the actual Digestive biscuits are made, but the Stockport site makes Penguins, Jaffa Cakes and, crucially, the delicious chocolate mix that sits atop the chocolate digestive.

The current recipe for the biscuit dates all the way back to 1892, but it wasn’t until 1925 that some genius would have the idea of covering the crunchy, malty, moreish biscuit with a layer of melted chocolate.

The McVities factory

The McVities factory

As McVities marks the 100th anniversary of what is consistently ranked as Britain’s favourite biscuit, the Manchester Evening News was invited down to take a peek behind the scenes at just how that famous chocolate is made.

As a confirmed sweet tooth, which shows little sign of abating as my 20s march onward, I, like many I’m sure, have history with these biscuits.

I think we in Britain are especially attached to, and protective over, our food. After all, it carries memories, and sensory associations too: the clink as they spill onto a plate, the crunch of the first bite, the snap as you halve them and dunk them into tea (and then inevitably rush to wolf the rest down before it falls to pieces).

Wrapped in tinfoil and popped into lunchboxes; laid out on plates at church coffee mornings; the first thing I grab when off to see a friend who’s had a bad day.

Inside the control room

Inside the control room

My parents actually used them as a bribe to get me to eat apple slices as a child – though I’m not sure that’s a use case McVities will be keen to advertise any time soon.

Suffice it to say, the roots run deep. But enough eulogising – how do they actually make that chocolate we all know and love?

Our journey starts at the very top of the factory. This more modern extension to the Edwardian building was built in the 1980s and now houses, among many other things, enormous silos of sugar some 40 ft high.

Silos filled with sugar (Image: Manchester Evening News)

Silos filled with sugar (Image: Manchester Evening News)

But as soon as you set foot inside the building there is a powerful, pervasive and mouth-watering scent that I’ve been wondering ever since about how to describe.

Imagine Augustus Gloop’s fever dream. Imagine standing over a bowl of melted chocolate and just breathing in. Words fail me other than to implore you to think of the richest, most chocolate-y smell you can imagine, then multiply that by a hundred.

Standing on a metal mesh floor at the very top of the silos, you can feel your stomach swooping as you look down at the floor some 30 ft below you, and the true scale and size of an operation that makes 18,000 tons of chocolate a year – an Olympic swimming pool’s worth every month – starts to sink in.

Tour of the McVities Factory in Stockport(Image: Manchester Evening News)

Tour of the McVities Factory in Stockport(Image: Manchester Evening News)

The sugar is grown in the UK, we are told by general manager Anthony Coulson, and it is mixed with milk powder and cocoa (mainly from the Ivory Coast) to an expert recipe. The Stockport factory makes the chocolate for the milk and plain (dark) varieties of biscuit, as well as the gold caramel variety on occasion.

From the silo room we are led to a kind of control centre. Here, a multi-monitor set-up (looking at once very modern and also retro) allows engineers to view all the different mixes at once, and release them into the refiner system one by one.

Inside the McVities factory

Inside the McVities factory

With multiple failsafes at every step, it’s an intricate operation where ingredient quantities and sizes of the chocolate particulate are measured literally down to the micron (1/1000th of a millimetre).

At the first stage of mixing, the chocolate mixture looks like cement, dropping down onto a conveyor belt with the thudding consistency of wet sand. Wearing a pair of latex gloves, I am invited to take a pinch of the paste from the production line, and it tastes like a kind of chocolate sand. That trademark Mcvitites chocolate flavour is there, but the texture is quite coarse and grainy.

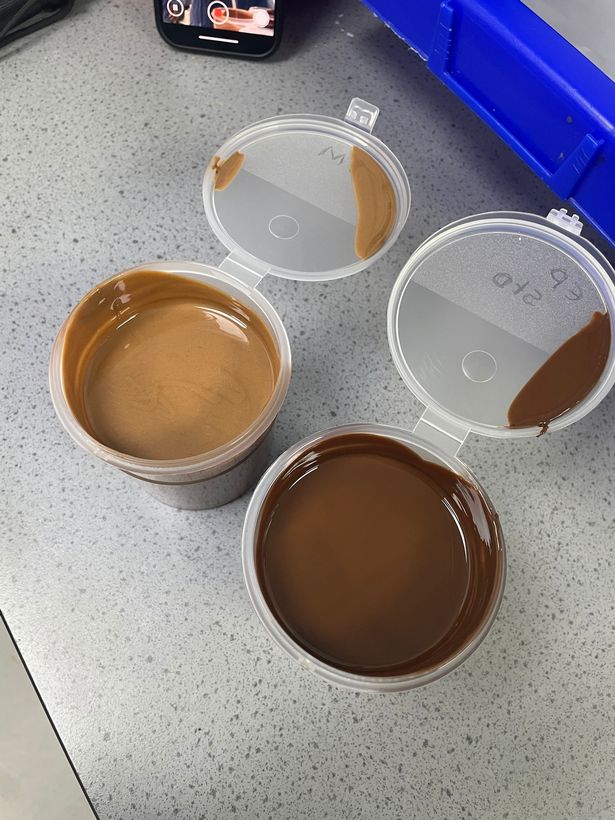

Chocolate heaven(Image: Manchester Evening News)

Chocolate heaven(Image: Manchester Evening News)

But no matter – that’s what the next step is for. From the control centre, the chocolate cement will drop into the main processing room below to be refined.

Like something out of Charlie and the Chocolate Factory, full of steeply climbing conveyor belts and enormous thrumming vats, this main room is startlingly free of people. The process is so precisely automated that just five people monitor it at a time – though the factory altogether employs around 450 people.

The main refining room

The main refining room

Stepping in here, you are enveloped in a fug of warm air – heated up by all the machines working, presumably – and that truly mouth-watering smell of rich chocolate.

At this next step, the chocolate passes over and through a series of refiners that look like enormous metal rollers, all compressing, refining and drying out the mixture until it resembles something like a broken up Flake.

We get to try another sample of the mix at this stage, still warm from the production line, and melting in the mouth in seconds like hot chocolate powder.

The ‘conches’ where the chocolate mix is emulsified(Image: Manchester Evening News)

The ‘conches’ where the chocolate mix is emulsified(Image: Manchester Evening News)

This is then ferried up on conveyor belts about 20 ft into the air where it is then poured into ‘conches’, a sealed, covered vessel where the chocolate ‘crumb’, as it is known, is mixed by giant metal blades with cocoa butter and other emulsifiers to get the desired taste and texture of the finished product.

Each conch contains a whopping six tonnes of chocolate, blending the mixture further for about six hours. Each has a tap, enticingly labelled ‘Chocolate sampling station’ – it’s tempting just to stand underneath it and drink from the tap.

But there’s no need as at this stage we are led to a mercifully cool laboratory off the main room. Here the chocolate mixture is analysed with spectrometers and sampled at every level of the process to check for quality.

Inside the McVities factory

Inside the McVities factory

A staff member brings out tubs of the different chocolate mixes: the plain (dark) and milk flavours, alongside a 90% which tastes like soil. But the other two are rich, creamy, and pure chocolate, the biscuit topping in its most concentrated form. We get a teaspoonful of each, which was more than enough, although I have visions of spreading it it on toast, or more likely, drinking it with a straw.

After this taste of heaven, we are off back to the top floor of the factory again: this time, to a ‘room’ more comparable to an aircraft hangar and kept strictly under lock and key as it is worth, quite literally, millions.

Behind the electronic door is a jaw-dropping sight: sixteen enormous silos, each filled with 36 tons of liquid chocolate. The air is thick with that chocolate scent again, so rich you can practically taste it, and growing even stronger when Anthony opens a hatch on one of the tanks and we peer down, aided by a torch, onto a glistening sea of chocolate more than ten feet deep.

A room worth millions…enormous silos filled with chocolate (Image: Manchester Evening News)

A room worth millions…enormous silos filled with chocolate (Image: Manchester Evening News)

From here, it is pumped straight into tankers and driven down to Harlesden, where within 48 hours it will be piped onto a Digestive biscuit and packaged up in plastic, ready for the supermarket shelves.

It’s a process that is timed to the minute to ensure drivers avoid rush hour both here and down south – and one that produces around 80 million packets of biscuits every year.

Will we still buy that many biscuits in a hundred years’ time? Will the chocolate digestive even still be around? Trends and fads come and go – but it’s hard to see this classic going out of style.