From left: Kelly Baggett, Fort Worth Innovation Coordinator; District 10 Councilmember Alan Blaylock; John Lauer, Founder and CEO of Adom Industries; City Manager Jay Chapa; and Michael Hennig, Economic Development Manager, in chambers after Fort Worth City Council unanimously approved $15 million in incentives for Adom’s $229 million cloud-connected electronics factory Tuesday night.

It’s official: Adom Industries is planting roots in Fort Worth.

After a unanimous City Council vote on Aug. 12 approving $15 million in incentives, Adom founder John Lauer says it’s “full steam ahead” on making the city the home of his $229 million headquarters-and-factory project.

“We are ready to plant our tree roots there and let those roots grow as deep as the Trinity aquifer,” Lauer told Dallas Innovates after Tuesday’s vote, noting the startup remains in stealth mode.

The decision capped a competitive site search in which Fort Worth emerged as a leading contender, alongside locations including Arizona, Tennessee, and Oklahoma. Lauer said those options were still under consideration until the council’s vote.

It’s a notable win for a city working to expand its semiconductor and advanced manufacturing profile—and for an entrepreneur with a track record of building and scaling.

Lauer previously co-founded Zipwhip, the business texting pioneer that Twilio acquired in 2021 in a deal worth $952 million at closing. “Adom,” he says, “should be even bigger.”

Bringing ‘Shenzhen Speed’ to the U.S. in Fort Worth

Adom Industries is building what Lauer calls the world’s first cloud-connected electronics prototyping factory. “We’re a data center to a large degree,” he said, “but for atoms, not bits.”

The concept allows engineers anywhere in the world to design, test, and prototype electronics remotely while robots in Fort Worth handle the physical work—then ship prototypes nationwide, “overnight, when they need their prototype boards.”

The facility will sit in North Texas’ logistics corridor, near Alliance and DFW airports, part of what drew Lauer to the region along with competitive electricity costs.

His technology aims to solve a fundamental time problem: “What takes minutes in software takes months in hardware.” Today, many hardware engineers still travel to Shenzhen, China, to access dense supply chains and rapid-prototyping capacity.

Adom’s cloud-connected factory aims to compress those months-long development cycles into near real-time processes, with engineers working from their laptops while AI-connected robots handle testing and production at the Fort Worth facility.

“This will be one of the most high-tech factories in the world,” Lauer said in an earlier interview with Dallas Innovates.

Motion carries: 11 Yea, 0 Nay

At Tuesday’s council meeting, District 10 City Councilmember Alan Blaylock praised the project’s potential impact. “I’m thrilled to move to approve this agreement to bring Adom Industries to Fort Worth,” he said. “Adom will develop and expand microelectronic prototyping in Fort Worth and create a semiconductor fabricating facility accessible through the cloud.”

Blaylock told the council, “More R&D activity will boost our GDP, attract specialized talent, [and] create opportunities for other companies that strengthen industry here,” as he welcomed Lauer during the proceedings.

“You’ve been a real trooper, sticking out this whole meeting,” Blaylock added, noting that the Adom vote came as the very last agenda item of the night. “But I think this is a high note to finish on.”

Councilmember Macy Hill, who seconded the motion, congratulated Lauer, who noted it was his first Fort Worth City Council meeting.

Following the vote, city innovation coordinator Kelly Baggett, who works on Fort Worth’s economic development innovation project, confirmed that the council’s approval landed the deal to bring Adom’s headquarters-and-factory project to Fort Worth.

District 10 City Councilmember Blaylock added in an emailed statement that the Economic Development Program Agreement “supports a cutting-edge project and positions Fort Worth at the forefront of technological innovation.

“I look forward to welcoming Adom Industries, the world’s first AI native cloud factory, to North Fort Worth, and I’m excited to see their platform revolutionize the microelectronics industry.”

$15M in performance-based grants

The approved incentive package provides up to $15 million in performance-based grants over 15 years, tied to Adom’s commitment to create 267 jobs with an average salary of $91,000 and invest more than $240 million in research and development.

Adom plans to expand over four phases from 2027 to 2033, starting with its current Alliance Texas location at 4400 Alliance Gateway Freeway and growing into additional Fort Worth facilities.

The company is also seeking $20 million from the Texas Semiconductor Investment Fund and $10 million from the National Science Foundation to support the project.

Lauer envisions customers ranging from defense contractors and major semiconductor companies like Texas Instruments to healthcare firms, startups, and universities seeking cloud-based access to expensive testing equipment.

Read our in-depth profile for more on the deal, how Adom’s technology works, and what it means for electronics manufacturing,

Don’t miss what’s next. Subscribe to Dallas Innovates.

Track Dallas-Fort Worth’s business and innovation landscape with our curated news in your inbox Tuesday-Thursday.

R E A D N E X T

-

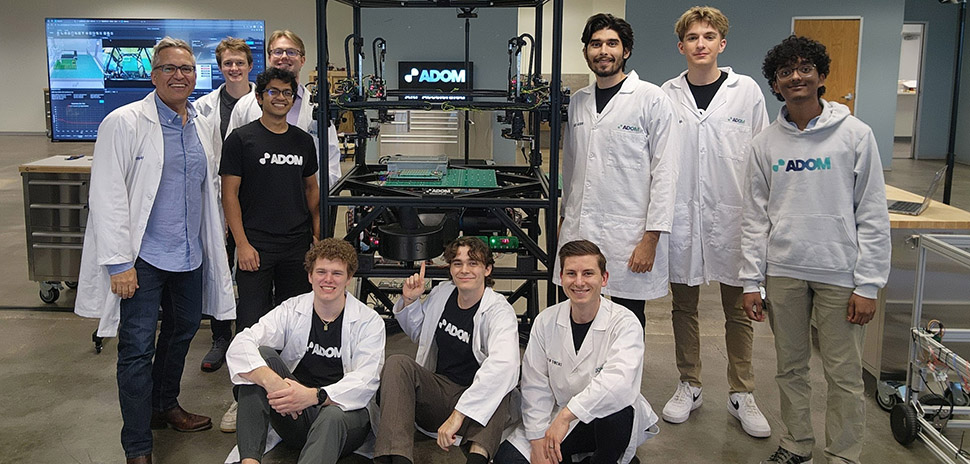

The stealth-stage startup, led by tech entrepreneur John Lauer—who sold his last company for nearly $1 billion—is developing what it calls the world’s first cloud-connected electronics prototyping factory. “This will be one of the most high-tech factories in the world,” said Lauer. The stealth-stage startup, led by tech entrepreneur John Lauer—who sold his last company for nearly $1 billion—is developing what it calls the world’s first cloud-connected electronics prototyping factory. “This will be one of the most high-tech factories in the world,” said Lauer. Update Aug. 13, 2025: The Fort Worth City Council voted unanimously on Aug. 12 to approve…

-

![A NASA illustration depicts the idea of a future air taxi hovering over a municipal vertiport. [Rendering: NASA/Lillian Gipson and Kyle Jenkins]](https://www.europesays.com/us/wp-content/uploads/2025/08/DRC-NTCOG-NASA-970-970x464.jpg)

The federal research laboratory slated for Texas A&M-Fort Worth will be focused on innovative aviation technologies—including drones, air taxis, and supersonic and hypersonic aircraft.

-

North Texas has plenty to see, hear, and watch. Here are our editors’ picks. Plus, you’ll find more selections to “save the date.”

-

Premature babies diagnosed with bronchopulmonary dysplasia (BPD) face the risk of rehospitalization, delayed brain development, and respiratory problems throughout childhood. No FDA-approved therapies are available for BPD—which is why the new FDA designation for AyuVis’s drug candidate, AVR-48, could lead to game-changing impact.

-

“Some moments are priceless.” Fort Worth-based Bison Coolers …. reflecting on the company’s Google Super Bowl ad appearance, via LinkedIn. Despite the Cowboys missing out on Super Bowl LIX, a Fort Worth family business scored big during the championship game. Bison Coolers, founded by former Southwest Airlines employee Jeremy Denson in 2011, was featured in Google’s “50 States, 50 Stories” campaign highlighting how small businesses use AI technology and the tech giant’s Gemini for Workspace. The opportunity almost slipped away when Denson initially dismissed Google’s email as a routine update while at a trade show, according to the Dallas Business…