The materials that keep spacecraft from melting and power plants from corroding typically require energy-intensive manufacturing at extremely high temperatures. That constraint limits where and how ultra-durable materials can be used.

Now, a research team led by Southern Methodist University may have found a way around that. In a study published in Science, SMU engineers detail a new material that can withstand extreme heat and chemical exposure, but can be 3D-printed or spray-coated at room temperature.

The research was supported by the U.S. National Science Foundation and the U.S. Department of Energy’s National Nuclear Security Administration.

The SMU team — together with collaborators at the University of Illinois Chicago, Stockholm University, and the University of Washington — “for the first time” figured out how to make the material for cost-effective and energy-efficient manufacturing.

A new approach to extreme environments

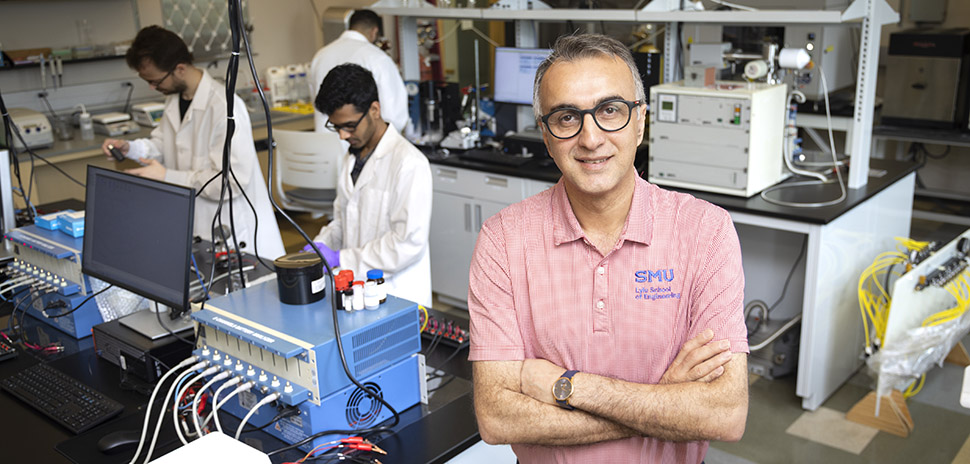

The material—called a high-entropy oxide nanoribbon—was developed by a research team led by Amin Salehi-Khojin, the William T. Solomon Chair of Mechanical Engineering at SMU’s Lyle School of Engineering.

“These nanoribbons exhibit outstanding resilience under extreme conditions and remarkable mechanical properties,” Salehi-Khojin said in a statement.

The material maintained its structure at temperatures up to 1,000°C, withstood pressures up to 12 gigapascals, and showed no degradation after seven days in highly acidic and basic environments.

SMU said it could have broad applications in aerospace, energy, and electronics, all fields where materials are often pushed to their limits.

Nanoribbons, entropy, and fruit salad

Nanoribbons are extremely thin, narrow strips of material, usually just a few nanometers thick. The version developed by the SMU-led team is part of a class of materials known as high-entropy oxides.

High-entropy materials are made by mixing five or more elements in roughly equal parts. Unlike most materials that are dominated by one or two elements, this “equal mix” approach creates what scientists call high entropy or a highly disordered atomic structure.

That disorder is actually a benefit, making the materials stronger, more resistant to heat, and more durable in corrosive environments.

SMU compares it to making a fruit salad using equal parts apples, bananas, grapes, oranges, and berries, making it a more balanced mix than typical recipes.

“This even distribution leads to a highly disordered atomic structure… which can enhance the material’s strength,” Salehi-Khojin said.

A new method for low-dimensional materials

The research team developed a two-step synthesis method to fabricate the nanoribbons.

According to Ilias Papailias, the study’s co-author and a research assistant professor in SMU Lyle’s Mechanical Engineering Department, the team used a sulfur-based etching step to create a 2D structure, then oxidized that structure into one-dimensional ribbons. The process allows precise control over the ribbon size and width.

“This technique provides over two orders of magnitude control on the width and size,” Papailias said. He added that extended oxidation leads to full conversion into 1D systems—confirmed through in-situ experiments.

The resulting 1D-HEO (high-entropy oxide) ribbons offer a combination of strength, heat resistance, and chemical durability that’s rare among materials that can be fabricated without high temperatures.

Potential for industrial applications

While additional testing is needed, SMU said the results show strong potential for use in industries that require materials to perform in extreme environments.

“This new method can revolutionize the material science field by introducing new entropy structures,” Salehi-Khojin said.

Maddie Preston contributed to this report.