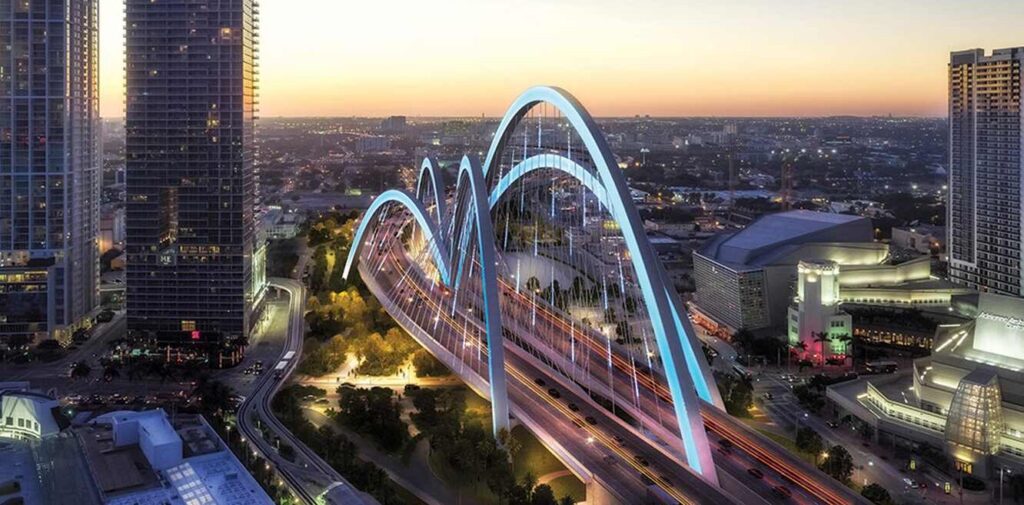

A final rendering courtesy of the Florida Dept. of Transportation

A final rendering courtesy of the Florida Dept. of Transportation

In Miami, the most “complex bridge in the world,” has passed the midway point of completion, with 3 of its 6 magical arches now firmly in place.

Known as “The Fountain Bridge,” the arches are inspired by streams of water the lead developer saw in a Barcelona fountain. It will sit on I-395 and be lit with LED lights to represent the colorful life and heritage of the city of Miami.

The Fountain Bridge as it currently sits – courtesy of the Florida Dept. of Transportation

The Fountain Bridge as it currently sits – courtesy of the Florida Dept. of Transportation

Though its completion will add a rapturous feature to the city’s skyline, the expected completion date has already been extended 5 years past its original, 5-year timeline, owing not only to the massive work going on simultaneously on I-395 and nearby interchanges the bridge will connect, but also to the fountain design itself.

Engineering News Record spoke with project leads about the bridge, who said that it was the most complex they had ever conceived of or worked on.

“This is the most complex design-build segmental bridge, honestly, in the world,” says Riccardo Castracani, business development director for Rizzani de Eccher, the firm responsible for precasting, or at least attempting to precast, the majority of the bridge’s 345 arch segments.

“We’ve never encountered something of this magnitude. As complex as it looks from afar, you can multiply that by ten,” when viewed close up.

By the numbers, the scale of the materials should give an indication as to the project’s scope. More than half a billion cubic yards of earth will be moved, and the arches will require 10 million pounds of just post-tensioning cables. 1.4 miles of interstate highway and several state routes will also be redeveloped to ease current traffic headaches.

The central pier, from which all 6 arches sprout from, will be built with 5,000 cubic yards of concrete set in place, with 1.7 million pounds of steel reinforcements. The superstructure is being built concurrently, and will be mounted on between 19 and 55 staying cables per arch to transfer their weight to the arches. Additionally, the bridge has had to be designed to withstand wind speeds of 140 mph.

Cabling on typical suspension bridges is uniform and unidirectional, but because each arch stands alone, is of different size to the others, and supports different components of the superstructure, the challenges are significant.

A close up on the central pier from which the six arches are in construction – credit, Florida Dept. of Transportation

A close up on the central pier from which the six arches are in construction – credit, Florida Dept. of Transportation

“Depending on where you are in the arch, and which way the cables are pulling, you may have post-tensioning on one side and not the other,” Mike Lamont, major bridges technical director for HDR, the engineering firm of record on the project, told ENR.

“It’s not just the final condition we’re designing for; it’s all of these intermediate construction stages. Cables are pulling on the arches from different angles, which results in a lot of bending in the arches that is an unconventional loading condition for an arch,” he said.

Some of the precast segments of the arches have, as Castracani mentioned, had to be cast according to individual specifications—such as interior cable anchorages where post-tensioning is carried out on just one half of one segment, and maybe just one corner on the next one. Sometimes it would take a week just to cast a single arch segment.

BRIDGES TO LOOK FORWARD TO: Gorgeous Suspension Bridge Set for Completion in 2025 Will Make History Immediately – (LOOK)

Another architect responsible for overseeing the joining of each arch segment noted similar challenges, saying they hadn’t dealt with a single segment for which the process of joining and tensioning could be replicated to another. The procedure for each one had to be planned out individually.

Some arches just aren’t behaving in ways that were predicted, and challenges arose on Arch 5 that saw work extended multiple months beyond schedule.

MORE AMERICAN ENGINEERING: Charlotte Cycling Thoroughfare to Finally Get Long-Awaited Bridge–and She’s A Beauty

Through it all though, the work is coming together, and the dramatic shape of the bridge is beginning to become more and more defined. Chief architect and engineer Donald McDonald is looking forward to the completion. It will grant Miami a one-of-a-kind object of stunning technical complexity and form.

“It’s so unique, there’s nothing like it in the world,” he says. “So it’s really going to be a dynamite thing.”

SHARE This Remarkable Engineering Challenge With Your Friends On Social Media…