Originally designed for video games, graphics processing units (GPUs) now power much of today’s AI – from voice assistants to self-driving cars. Unlike regular computer chips, GPUs have thousands of small cores that handle many simple tasks at once.

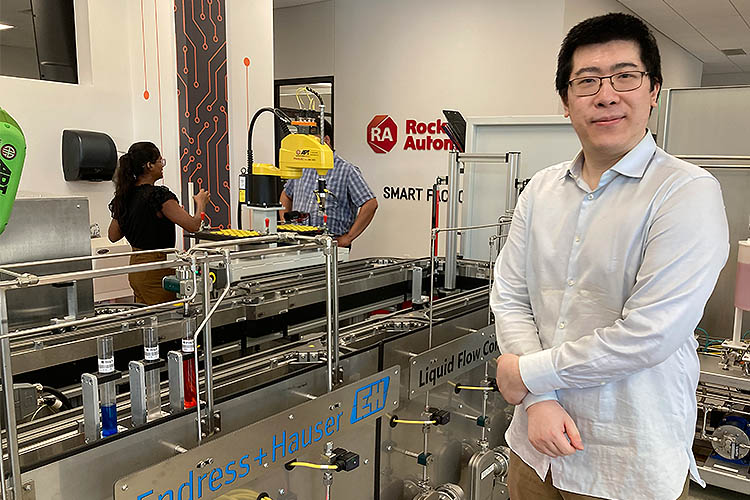

GPUs that are built into larger devices process data locally – at single locations – called “the edge.” This approach saves power, speeds results, and keeps information more private because it doesn’t have to be sent to the cloud, said Roger Shen, assistant professor of electrical engineering.

Edge computing can handle small, local AI models that later can contribute to larger shared models through a process called “federated learning,” while preserving data security.

A GPU, just larger than the palm of your hand, was created for gaming, but can perform many simple, repetitive tasks simultaneously, accelerating mathematical calculations. They can be deployed at individual locations where they can process AI “at the edge” – right were the data is generated.

A GPU, just larger than the palm of your hand, was created for gaming, but can perform many simple, repetitive tasks simultaneously, accelerating mathematical calculations. They can be deployed at individual locations where they can process AI “at the edge” – right were the data is generated.

Another key to energy savings is through better-tailored algorithms, Shen said.

A tradeoff

Efficient algorithms can reduce the number of calculations needed and handle larger data sets without overwhelming servers.

“My focus is on the algorithm side,” Shen said. “This provides a promising solution to the energy consumption issue because an embedded system is simpler – it’s just focused on a specific task.”

There’s always a tradeoff, Shen noted. Using less power often means a model is less precise. But not every task requires perfection. In manufacturing, for example, AI may only need to decide a yes-or-no question: “Is this part defective or not?”

In such a case, a small loss in accuracy is inconsequential and worth the savings in speed and energy.

Embedded AI processing can flag defects in real time and prevent breakdowns before they happen, shaping the next wave of smart manufacturing.

Shen has seen the payoff firsthand. Working with battery manufacturer Clarios, his team used machine learning to analyze why individual cells that passed inspection sometimes failed when assembled into packs.

“Our job was to dig into those production data to see if there was some circumstance that explained why they weren’t playing well together,” Shen said.