An 18‑ft‑diameter section of the Los Angeles Effluent Outfall Tunnel partially collapsed late Wednesday, briefly trapping 31 construction workers roughly six miles from the only shaft access.

Crews from the Los Angeles Fire Department’s Urban Search and Rescue units and paramedics entered the tunnel and found that colleagues of the trapped men had already climbed over a 12-ft to 15-ft pile of soil and debris to reach and evacuate them via a tunnel transport vehicle.

According to a statement by the Los Angeles County Sanitation Districts, the incident occurred around 7:45 p.m.; by 9:20 p.m., all 31 workers were back on the surface, uninjured and had been released after a medical evaluation.

“What started out as a very frightening evening… I just have to tell you that we’re all blessed today in Los Angeles. No one was injured. Everyone is safe,” L.A. Mayor Karen Bass said at an early-morning press conference.

The incident occurred within the joint Clearwater Program’s Los Angeles Effluent Outfall Tunnel, a $630.5-million, seven‑mile‑long conduit designed to carry treated wastewater from the Hyperion Water Reclamation Plant to ocean outfalls near San Pedro, about 7.5 miles north of Long Beach. The tunnel lining consists of bolted and gasketed precast concrete segments which are installed after the TBM has passed.

Interim Fire Chief Ronnie Villanueva added that more than 100 firefighters, drones, search canines and hazardous materials specialists were staged for what was quickly escalated to a major emergency tunnel rescue at 7:58 p.m.

The Clearwater Project replaces existing wastewater tunnels built in the 1930s and 1950s.

Map courtesy Los Angeles County Sanitation Districts

In a statement, the sanitation district said the collapse posed no environmental risk as the tunnel was not in service.

Cal/OSHA and the Los Angeles County Sanitation District have launched joint investigations into the collapse, which engineers say may have been precipitated by “squeezing ground” conditions—when soft or fractured soils exert inward pressure on the TBM shield.

The Sanitations Dept. said Clearwater Tunnel operations have been halted while this investigation takes place and there is no timeframe for how long the process will take.

Construction Operations

The LAFD said the trapped men were operating at the tunnel face—monitoring tunnel boring machine controls, removing excavated soil, and guiding new ring segments into place—when the collapse occurred. Four additional crew members had backup roles just behind them, assisting in muck removal and equipment handling.

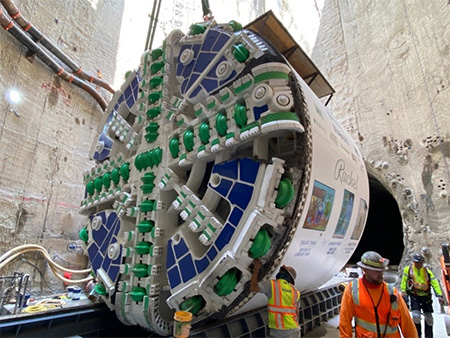

The assembled TBM head prior to launch in 2021.

The assembled TBM head prior to launch in 2021.

Photo courtesy Los Angeles County Santitation Districts

FlatironDragados serves as the prime contractor, employing a Herrenknecht TBM named “Rachel,” to bore 18-ft internal-diameter sections 450 ft below existing roadways.

According to the LAFD, the failure occurred in the soft‑soil portion of the alignment beneath the city of Wilmington. The harbor‑area alluvium there is more susceptible to “squeezing ground” conditions when punctured by a TBM.

As the TBM advances, it installs a precast, segmental concrete liner in 5-ft rings immediately behind the cutterhead. This “construct as you go” approach provides continuous support to the freshly excavated ground and limits deformation, according to the agency.

According the sanitation district, the TBM is expected to finish boring the tunnel this year and construction will be completed in 2027. The new line is scheduled to be operational in 2028. The tunnel will replace aging pipelines installed in 1937 and 1958, cross-fault seismic risks, and overflow during major storms.

Parsons Corp. and McMillen Jacobs Associates led the geotechnical and design phases, using deep-bore and soil analysis to map ground conditions.

FlatironDragados’s safety plan includes recurring inspections of the segmental liner, emergency refuge areas every 1,500 ft and on‑call rescue drills in coordination with LAFD.

Construction work engines operate exclusively underground, with daily pre-shift safety briefings and continuous atmospheric monitoring in trapped-entry zones. Continuous atmospheric monitoring and on-call rescue drills with LAFD are integrated into the construction schedule, which limits all surface disruptions to weekdays and restores sites to pre-construction conditions upon completion.