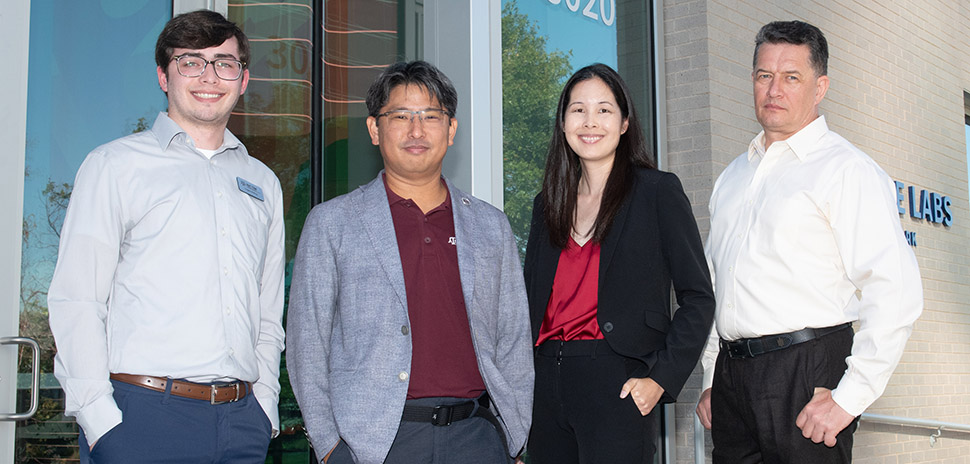

Ribbon-cutting ceremony for the National Center for Therapeutics Manufacturing satellite campus [Photo: UTA]

UTA and the Texas A&M Engineering Experiment Station have opened a new biomanufacturing training and research hub at Pegasus Park focused on workforce training and early-stage biotech development.

The National Center for Therapeutics Manufacturing satellite campus, or NCTM2, offers hands-on training, state-of-the-art lab space and support for early-stage biotech companies. It sits inside Bridge Labs, the two-story, 135,000-square-foot facility that’s quickly become a key life sciences asset in Dallas.

At the opening, UTA President Jennifer Cowley framed the investment as a long-term workforce play designed to connect education, research, and commercialization.

“Together, we are strengthening the biomanufacturing workforce and expanding access to hands-on training,” Cowley said. “We’re also creating pathways for students, researchers, and entrepreneurs to bring lifesaving innovations from concept to market.”

She said the goal is to help North Texas compete for biotech talent as demand for advanced manufacturing skills continues to rise.

UTA President Jennifer Cowley at NCTM2 [Photo: UTA]

A statewide partnership built for workforce growth

NCTM2 is a joint effort between UTA’s Institute for Biomanufacturing and Precision Medicine of North Texas and Texas A&M Engineering Experiment Station, or TEES. The collaboration brings together engineering depth, biomanufacturing expertise, and biomedical research to address workforce gaps identified by life sciences companies across the state.

Rodney Bowersox, deputy director of TEES—a state research agency within the Texas A&M focused on conducting applied engineering research to drive innovation and economic benefit—said the partnership allows each institution to contribute its strongest capabilities.

“By linking our strengths in engineering and biomanufacturing with UTA’s leadership in biomedical innovation, we’re building a training ecosystem that is broader, stronger, and more agile than anything we could build alone,” Bowersox said.

Demand for workers with bioprocessing and good manufacturing practice (GMP) experience continues to grow, particularly as the U.S. works to expand domestic production of vaccines, therapeutics, and other biologics, according to the partners. Regional training hubs like NCTM2 are expected to play a central role in meeting that demand.

Labs and tools for biotech startups in Dallas-Fort Worth

Startups, in particular, often face challenges finding affordable lab space or access to biomanufacturing tools, and with NCTM2, those companies have another option to grow locally.

Dallas City Councilwoman Laura Cadena said the partnership helps keep innovation and manufacturing rooted locally.

“By expanding biomanufacturing capacity and accelerating the development of new medical technologies in partnership with Texas A&M Engineering Experiment Station, UTA is helping ensure that lifesaving innovations are created—and deployed—right here in our community,” Cadena said.

She said the work also supports local hospitals and care providers while bringing new technologies closer to patients.

Positioning North Texas for the next era of therapeutics

Jon Weidanz, UTA’s senior associate vice president for research and founding director of the university’s Institute of Biomanufacturing and Precision Medicine for North Texas, or IMPRINT, said the initiative lays groundwork for future growth.

The new satellite campus aligns with national efforts to strengthen the U.S. bioeconomy and accelerate production of next-generation medicines. And in North Texas, it reinforces the region’s role at the intersection of research, training, and industry, according to the partners.

“We are proud to bring IMPRINT’s expertise in precision medicine, synthetic biology, and translational therapeutics to this transformative partnership,” Weidanz said. “Together, we are building the backbone of Texas’ next-generation biomanufacturing ecosystem and positioning North Texas as a national leader to produce the medicines of the future.”

Don’t miss what’s next. Subscribe to Dallas Innovates.

Track Dallas-Fort Worth’s business and innovation landscape with our curated news in your inbox Tuesday-Thursday.

R E A D N E X T

-

The new center at Bridge Labs will train the workforce powering North Texas’ biotech boom—helping startups speed therapies, vaccines, and breakthrough biologics from lab bench to patients. Funded in part by Lyda Hill Philanthropies, the National Center for Therapeutics Manufacturing Satellite Campus is set to open this summer.

-

The investment strengthens UTA’s pipeline for high-demand engineering talent and supports research on AI-enabled safety systems for nuclear plants.

-

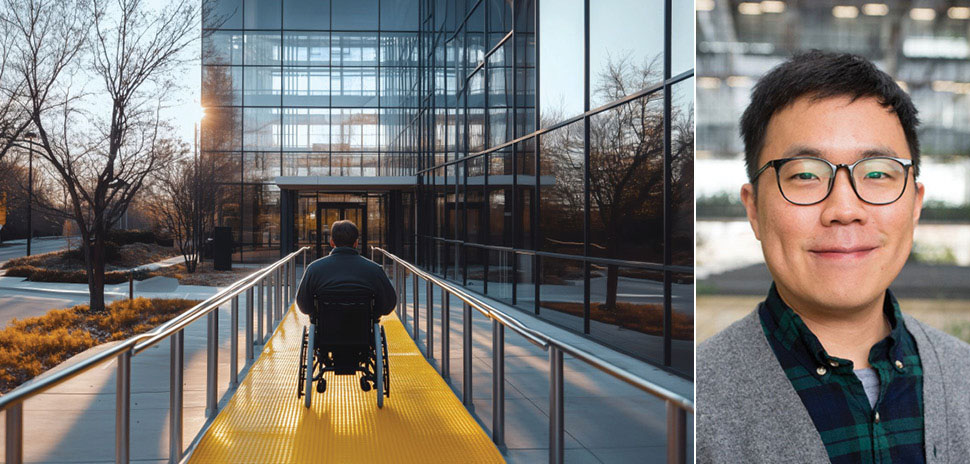

Backed by a National Science Foundation grant, the project’s key innovation is WHEELCOM—a device that captures wheelchair movement data to help engineers design smarter, more inclusive buildings.

-

The pilot will test Last Energy’s 5-megawatt PWR-5 design at Texas A&M–RELLIS while the company advances a plan for 30 commercial microreactors in Haskell County northwest of Dallas-Fort Worth to serve data center growth.

-

Founded in 2012, Universal DX is focused on “cracking cancer’s code” via its multi-omics and machine learning models. Starting with colorectal cancer, it’s building a “multi-cancer platform” that can ID the unique DNA regions associated with different types of cancers.