[Image: Tetiana Mykhailenko/istockphoto; DI Studio]

Manufacturing engineers have long struggled with materials that crack under stress—limiting how tough they can make everything from airplane wings to car frames. A University of Texas at Arlington researcher is looking to nature for answers.

Shiyao Lin is using 3D printing to re-create the crack-resistant structures found in bamboo stems and conch shells. By combining their structural principles into hybrid composites, Lin aims to develop materials that could outperform current options.

His project is one of six recently awarded grants under UTA’s Research Enhancement Program, which supports early-stage research with the potential to attract funding from federal agencies and nonprofit foundations. The program is administered by UTA’s Office of the Vice President for Research and Innovation.

Shiyao Lin, Department of Mechanical and Aerospace Engineering, College of Engineering at UTA

“This grant will train graduate and undergraduate students with analytical and hands-on skills,” Lin said. He added that the project would help broaden engineering students’ knowledge of zoology and biology.

Lin’s approach explores how natural structures prevent damage at a fundamental level—bamboo’s cellular design helps deflect cracks, while conch shells use layered compositions to resist fractures.

By combining multiple biomimetic designs through multi-material 3D printing, his team is creating composites that could make aircraft components, automotive parts, and protective equipment more durable.

The first step is to create a hybrid design inspired by the two natural models. The team will use a multi-material 3D printer to build the structures, then conduct mechanical testing alongside computational modeling to evaluate how well they hold up under stress.

Lin, a professor in the Department of Mechanical and Aerospace Engineering in UTA’s College of Engineering, titled his project “Novel Damage-Tolerant Composites Enabled by Hybrid Biomimetic Designs and Multi-Material Additive Manufacturing.”

Don’t miss what’s next. Subscribe to Dallas Innovates.

Track Dallas-Fort Worth’s business and innovation landscape with our curated news in your inbox Tuesday-Thursday.

R E A D N E X T

-

The Tech Transfer Showcase spotlights life science innovation at universities and strengthens the development of future leaders and entrepreneurs, BioNTX said. Here are the six university finalists who’ll be pitching at the summit.

-

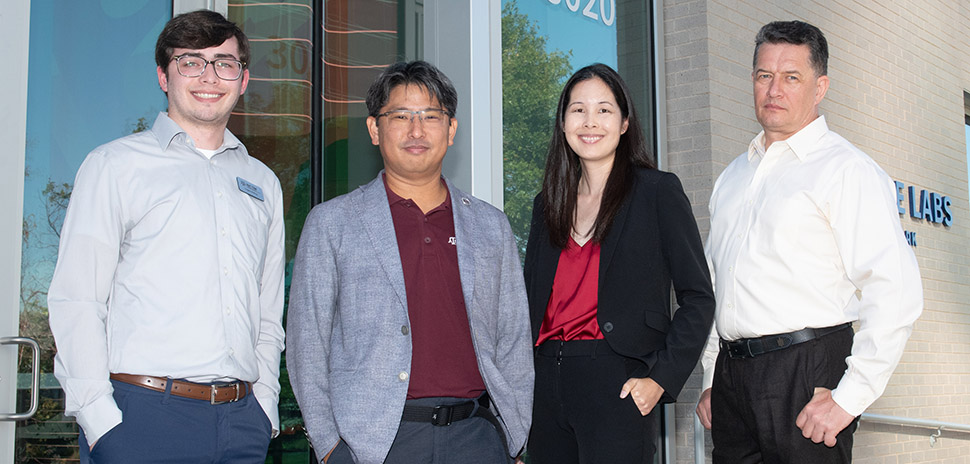

The new center at Bridge Labs will train the workforce powering North Texas’ biotech boom—helping startups speed therapies, vaccines, and breakthrough biologics from lab bench to patients. Funded in part by Lyda Hill Philanthropies, the National Center for Therapeutics Manufacturing Satellite Campus is set to open this summer.

-

The study of data from past storms includes researchers from multiple universities as well as international partners from hurricane-prone regions including the Bahamas, Jamaica, and Costa Rica.

-

University of Texas at Arlington reported its projects contributed $59 million to the national economy last year, an increase of 39% from 2023, according to a new report from the Institute for Research on Innovation and Science (IRIS).

-

Backed by a National Science Foundation grant, the project’s key innovation is WHEELCOM—a device that captures wheelchair movement data to help engineers design smarter, more inclusive buildings.